BIM’s technology-enabled approach to accurately representing buildings in a three-dimensional space encourages collaboration across all phases of a building project from planning and design to construction and management.

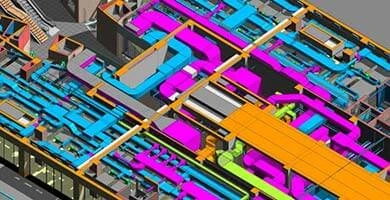

Tools such as Revit and Navisworks facilitate the creation of detailed and data rich models in BIM. These models are backed by extensive databases, enabling a comprehensive perspective at each stage of a project. With BIM, MEP consultants can navigate designing and optimization in a manner that closely reflects physical realities.

Table of Contents

Incorporating BIM within MEP consulting workflows has set new standards in excellence to optimize designs, resolve clashes, reduce rework, and enhance project quality.

It allows MEP consulting firms to visualize and simulate every component of the MEP system for faster decision-making and problem-solving throughout the entire project.

BIM integration has entirely changed our approach to MEP design and installation and our insights in this helps MEP consultants understand this change. We dive into fundamental concepts of BIM MEP modeling, its benefits, performance strategies, challenges, case studies and BIM MEP trends. Whether you are new to BIM or an established MEP consultant, this guide promises to be a handy reference.

Building Information Modeling (BIM) plays an important role in fueling precision in MEP systems design, reducing errors, and enhancing project collaboration.

Traditional techniques pose many problems for MEPF (Mechanical, Electrical, Plumbing and Fire protection) consultants, such as inaccuracies, inefficiencies and frequent clashes in layouts or drawings. Outdated 2D drawings are prone to errors, workflows are often isolated, and there’s a noticeable lack of detailed visualization.

BIM-based Revit MEP modeling provides solutions to these obstacles. It helps MEP consultants refine and improve the planning, design, and construction processes related to MEP systems. With BIM tools, MEP consultants can enhance project accuracy and achieve better MEP coordination and efficiency throughout the project lifecycle.

The collaborative nature of BIM drives coordination between various disciplines, including architecture and structure, mitigates conflicts, and creates a system driven by optimized performance. As clients increasingly demand new-age BIM capabilities for their construction projects, it is imperative that MEP consultants reinforce their present workflows with BIM processes and tools.

Unlock the power of precision with MEP BIM drawings and details

Get Started »BIM objects represented within physical building components in digital and 3D forms contain geometry and data attributes. MEP consultants need to use BIM objects in 3D models and specify MEP systems precisely.

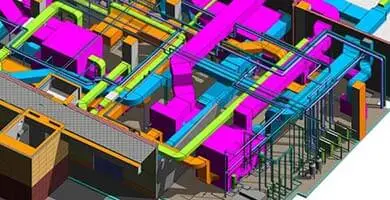

Clash detection entails critical BIM processes that identify and resolve conflicts between various MEP building components. For MEP consultants, it ensures that MEP systems do not influence one another or the architectural and structural disciplines.

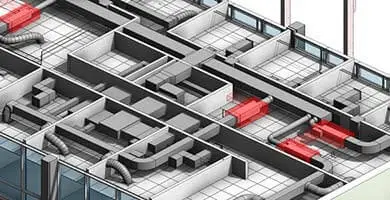

Federated 3D models unify trade-specific BIM models that includes Architecture, Structure, and MEP into a single coordinated 3D model. The integration of all these models into a single coordinated and clash-free model reduces errors and mitigates rework.

1. Assessing Current Workflow: The first step for a MEP consultant includes identifying opportunities for BIM implementation by understanding existing workflows and aligning them with client or project requirements. For this, the following needs to be analyzed:

2. Staff Training and Skill Development: Investing in staff training is critical to successfully implementing BIM. MEP professionals need to acquire these skills to deploy workflows and use BIM tools. It is crucial to equip MEP professionals with the necessary skills and knowledge to effectively implement BIM. For this, MEP consultants need to evaluate the following:

3. Select the Right BIM Software in MEP Consulting: Using the right BIM software is essential to facilitate compatibility with multiple trades, usability, and software capabilities for 3D MEP modeling.

Choosing BIM software that aligns with the needs of MEP consulting ensures compatibility, usability, and robust 3D MEP modeling capabilities. To choose the right software, the following needs to be kept in mind:

A BIM Execution Plan outlines project-specific BIM needs, milestones, and responsibilities. A BIM Execution Plan (BEP) drives greater clarity and consistency to execute projects.

Components of a BIM Execution Plan:

Benefits of a BIM Execution Plan:

Setting up standardized naming conventions for elements and files within the 3D BIM model draws-in organization and makes projects consistent at multiple stages.

Key Considerations:

By incorporating BIM Execution Plans and Naming Conventions, teams can establish a strong foundation for effective BIM implementation, fostering collaboration, consistency, and project success.

Leverage MEP BIM drawings to maximize productivity and minimize errors

Talk to us today »Creating MEP Models

Clash Detection and Resolution

Clash detection capabilities provided by BIM support MEP consultants in identifying and resolving interference issues between MEP systems and other building systems during early design, leading to significant rework reduction.

Performance Analysis

Documentation and Deliverables

An Irish engineering contracting firm specializing in MEPF systems outsourced its BIM project needs for an industrial warehouse project. The business need was to create coordinated and clash-free 3D models for a fire-protection system in 3D BIM. Deliverables also included fabrication drawings like builders’ work drawings for pre-fabrication.

The BIM engineers at Hitech CADD Services generated an information-rich 3D model that was coordinated and clash-free using Revit. Clash reports were generated in Navisworks. Accurate fabrication drawings and complete documentation sets were also reated at various stages of the project. The coordinated MEPF model helped the client –

Fire hose connection in corridor

Fire hose connection in corridor

Fire protection ceiling void model

Fire protection ceiling void model

3D Fire protection header room

3D Fire protection header room

A leading engineering and construction company in the Middle East partnered with Hitech CADD Services to work on an airport terminal project. These projects included office buildings, passenger terminals, and tiers, including North and South. The model had to be coordinated for Architecture, Structure, and MEPF.

The client partnered with Hitech CADD Services on the MEPF discipline to create a 3D MEPF model at LOD 400, generate clash detection reports, produce detailed quantity takeoff reports, and ensure that the MEPF layout and model worked in harmony with architectural and structural design. A team of MEP engineers generated a clash-free 3D model in Revit at LOD 400 by integrating architectural and structural models. The coordinated and clash-free 3D model in Revit at LOD 400 with other deliverables supported the client with –

BIM Clash Detection

BIM Clash Detection

Clash Resolution

Clash Resolution

MEP Clash Detection

MEP Clash Detection

MEP Conflicts Checking

MEP Conflicts Checking

Integration with IoT (Internet of Things): BIM and IoT synergize, allowing MEP systems to interact with smart buildings. Real-time data from IoT sensors aids predictive maintenance, energy optimization, and performance tracking. BIM enables Digital Twins, enhancing control and remote monitoring for increased efficiency and reduced operational costs.

AI and Machine Learning in MEP Design: AI and ML algorithms generate efficient MEP systems by factoring in constraints and parameters for optimized generative design. Simulations driven by AI and ML optimize MEP performance considering factors like weather, energy consumption, and occupancy. ML models predict potential issues for proactive maintenance, reducing downtime.

Cloud-Based Collaboration: Cloud-based BIM processes facilitate remote collaboration for MEP consultants in real time. Cloud storage ensures universal access to updated BIM data, enhancing coordination and decision-making. These solutions provide version control, minimizing data conflicts and enhancing MEP design precision.

Sustainability and Green Building Practices: BIM optimizes energy efficiency by aiding in the design and analysis of MEP systems, adhering to regulations. MEP consultants use BIM for life-cycle assessments, evaluating long-term impact and cost-effectiveness. BIM tools assist in selecting eco-friendly systems and materials, enhancing sustainability and building practices.

These future BIM trends for MEP consultants will reflect the importance of technology and sustainability in the AEC industry to enhance efficiency, systems performance, and environmental responsibility to design and implement MEPF systems.

BIM has proven to be more than a trend in the world of AEC and technology. It has fueled transformation to empower MEP consultants with faster, smarter and more precise work. As the MEP landscape continues to grow, stakeholders and clients expect BIM to be a standard practice in planning the building design process, construction and maintenance.

Furthermore, BIM facilitates collaboration across various teams and trades to remove silos and foster an integrated approach to the design and construction of MEP systems. The resulting project deliverables and results are efficient and sustainable.

To conclude, the benefits of BIM adoption for MEP consultants are indisputable. Following this detailed guide can support MEP consultants, and their firms position themselves as leaders in the AEC industry. It is time to embrace BIM with its processes and tools to secure a winning future for MEP consulting.

You may also like

Top 5 Global MEP BIM Outsourcing Companies

Top 5 Architectural BIM Companies to Outsource

Top 5 Sheet Metal Design Companies to Outsource