Are you struggling to communicate design intent on the shop floor? Our comprehensive sheet metal design services solve this problem with meticulous precision and efficiency. Our expert CAD teams specialize in mechanical CAD design for sheet metal, accounting for tooling capabilities, metal sheet types, required finishes, and critical dimensions, ensuring accurate and tailored shop drawings useful for sheet metal contractors, fabricators and manufacturers.

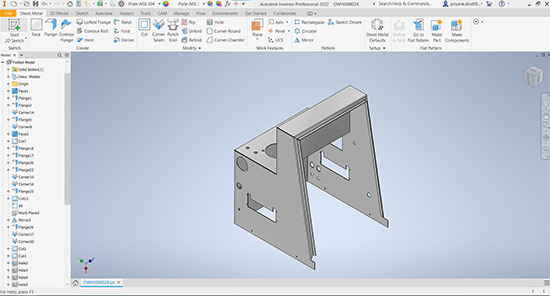

Whether it’s handrail connections or balcony assemblies, we provide clear communication and accurate hardware calculations for custom sheet metal fabrication. Streamline your workflow from pre-planning and bend schedules to welding and laser cutting, shearing and installation with BOMs, DXF files, shear and cut lists, and more. Boost production efficiency, minimize errors, and achieve exceptional results with Design for Manufacturability (DFM) for sheet metal, 2D flat pattern design and SolidWorks sheet metal models.

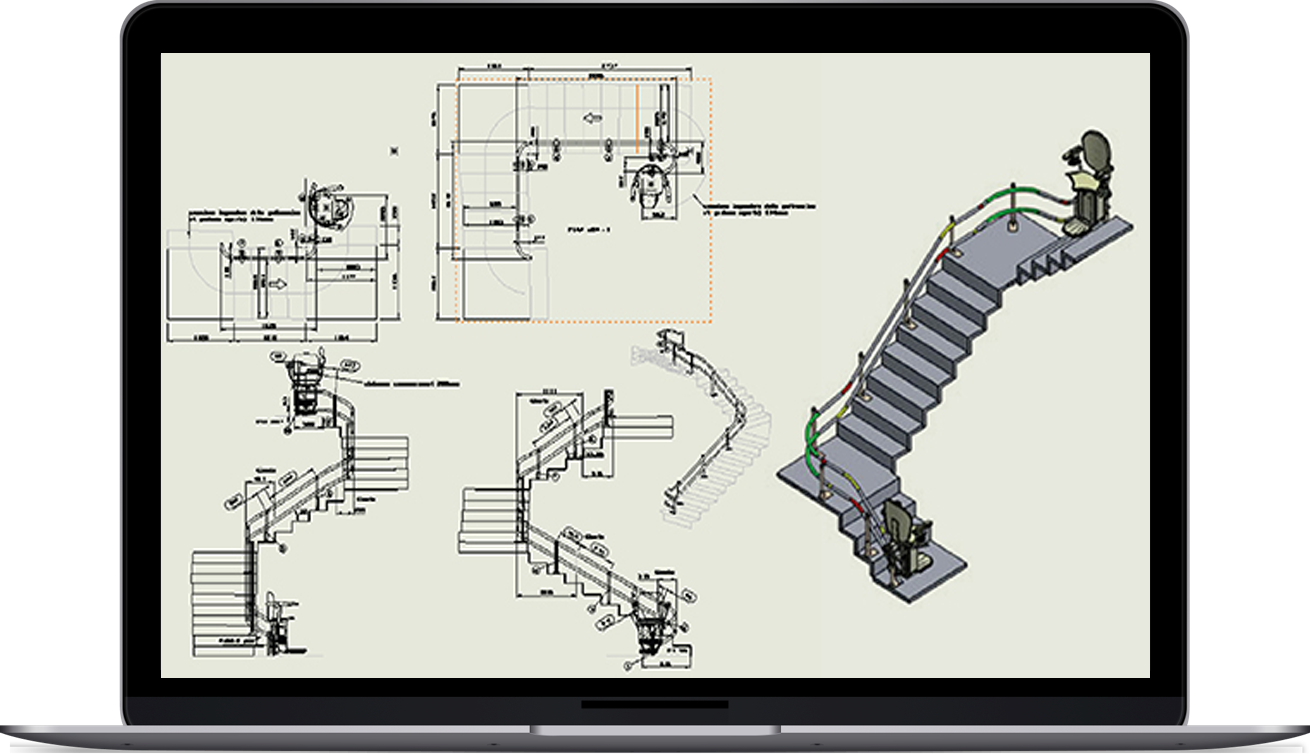

2D CAD Digitization

Get high-quality mechanical 2D conversions to CAD from paper plans, images, sketches or mark-ups.

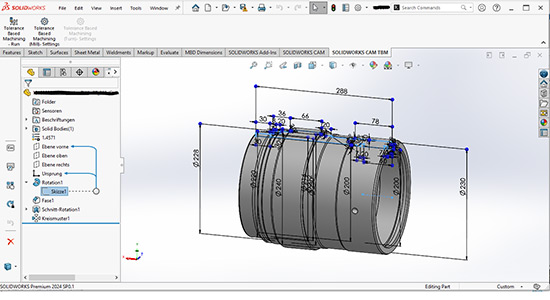

Sheet Metal Design with DFM

Sheet metal designing in CAD with k-factor, edges, miter, bends, flanges, rib, gusset, collars and more with DFM guidelines.

Layout Drawings

The simplest stage of drawings, layout drawings, help you define the scope of your project and rapidly create prototypes for assembly or fabrication drawings.

GA &Assembly Drawings

Our CAD team is fully equipped to cover basic project layout with individual component and assemblies to provide references.

Detailed Shop Drawings

Our pre-fabrication design and drafting team works tirelessly to get you the right sheet metal shop drawing with all the essentials addressed.

Fabrication Drawings &Estimation

Get comprehensive 2D fabrication drawings with coding and listing along with estimates for accurate bid values.

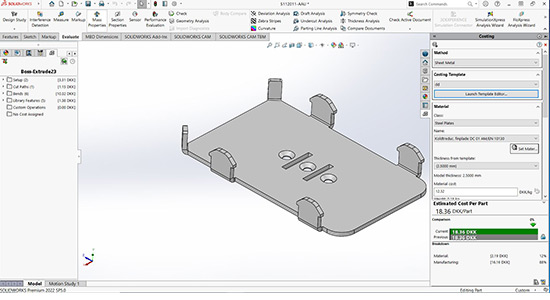

Automation in SolidWorks

DriveWorks implementation for custom sheet metal doors, louvers, etc. building products, as well as various architectural products.

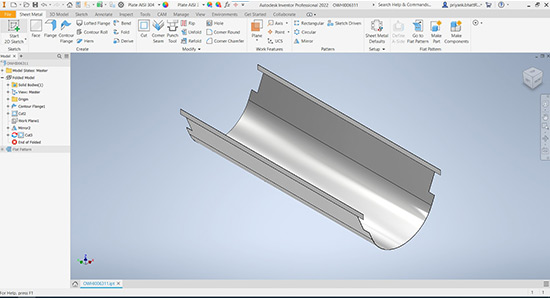

3D Modeling &Documentation

3D sheet metal modeling, assembly drawings, BoMs and other documents such as part list, DXF files, NC files etc.

GD&T

We follow ASME and other international standards as requested for our GD&T drawings.

We consider several factors such as material type, sheet thickness, required tolerances, and bend radii. Additionally, manufacturing capabilities, environmental conditions, and specific client requirements play crucial roles in completing the work accurately.

The two primary factors taken into consideration by our sheet metal design engineers for radius bending calculations are material thickness and the bend angle. These factors ensure precise and reliable bend formations in the sheet metal.

Yes, the CAD process is integral to our work, ensuring precision and accuracy in the design phase. It allows us to create detailed and exact models that meet all specified requirements.

The typical delivery time for sheet metal design is between 1 to 2 weeks. However, this timeframe can vary depending on the complexity of the project and specific client needs.

We price sheet metal work based on several factors including material costs, the complexity of the design, the time required for fabrication, and the volume of the order. Each of these elements is carefully evaluated to provide a fair and competitive price.

Our team utilizes industry-leading software such as AutoCAD, SolidWorks, and Inventor for designing sheet metal components. These tools help us create accurate and efficient designs.

Yes, we provide both flat patterns and comprehensive manufacturing drawings. These deliverables are essential for the fabrication process and ensure that the final product meets all specifications.

The deliverables of our sheet metal services include detailed 2D CAD drawings, 3D models, flat patterns, and bills of materials (BOMs). These documents provide a complete guide for manufacturing and assembly.

We adhere to Design for Manufacturing (DFM) guidelines by carefully considering material selection, manufacturing constraints, and ease of fabrication. This approach ensures that our designs are practical and efficient for production.

We take industry practices as standards. So, sheet metal fabrication involves processes such as cutting, bending, and assembling metal sheets into the desired shapes and structures. In contrast, sheet metal machining involves removing material from a solid block using tools like mills and lathes to create the final product.

Our sheet metal design experts deliver product-centric customized CAD drafting and detailing for a range of furniture and building products.