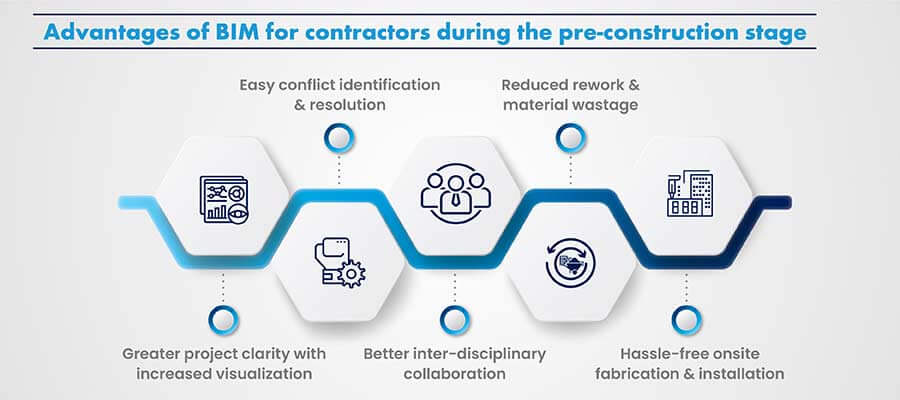

Implementing BIM for contractors enables early interdisciplinary conflict identification & resolution as well as increased project visualization. This empowers data-driven decisions and drives higher construction efficiencies.

The demands of a fiercely competitive market mandate building contractors to complete construction projects on time and within budget. A clear vision of the project supported by detailed, accurate and clash-free models, goes a long way in minimizing iterations, avoiding project delays and ensuring seamless and safe onsite installations.

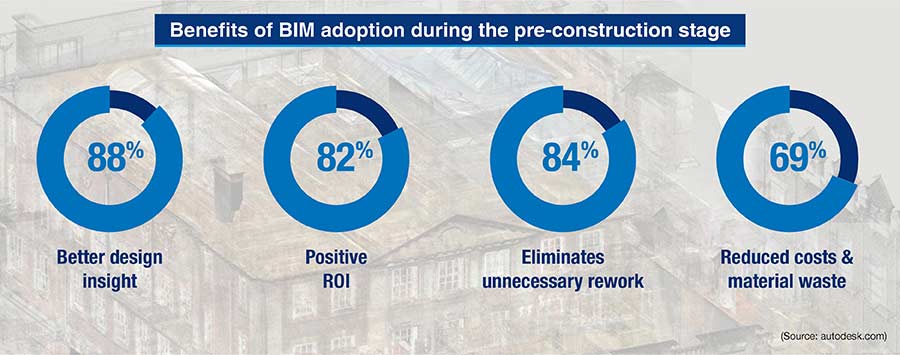

BIM implementation plays a key role in helping contractors enhance project efficiencies through reduced costs, lesser rework and timely deliveries. BIM level 3 or open BIM drives comprehensive collaboration across the planning, construction, and operational stages of the building asset lifecycle. A data-rich coordinated 3D BIM model defines the project scope at the preconstruction stage for enhanced constructability.

In this blog, we explore the challenges faced by contractors in the pre-construction phase and understand how embracing BIM for contractors in the initial stages of design can effectively address these issues.

Construction projects can become unmanageable if the initial design contains conflicts among various disciplines, whether it be MEP (Mechanical, Electrical, and Plumbing), architectural, or structural. Contractors working on complex construction projects using conventional tools and processes face challenges such as:

Based on Autodesk and Dodge Data & Analytics, 66% of general contractors report added costs from overtime or second shifts due to schedule slippage.

Maximize your costs and reduce rework with clash-free 3D BIM models.

Learn about our BIM modeling services NOW »Integrated architectural, structural, and MEP designs and layouts help contractors in gaining a comprehensive visualization of every aspect of the building. Shop drawings derived from an error-free and well-coordinated 3D BIM model ensure increased precision during the fabrication of building components and equipment. The use of Revit® families in the initial design process aids in customizing and streamlining component modeling and fabrication, facilitating seamless onsite installation.

The use of various Revit automation tools like Dynamo, APIs, and Macros in the preconstruction stage speeds up the design process and amplifies collaborative BIM. Augmented project deliverable quality and material management, greater design performance, better ROI, etc. are some of the advantages automation offers in preconstruction design.

An overall reduction of more than 35% can be observed in RFI coordination through the use of BIM.

Coordinated BIM model saves $7M with hassle-free installation for an airport in Oman

BIM Clash Detection

BIM Clash Detection

A general contracting company from Oman needed a clash-free coordinated model for an Airport project. The team at Hitech CADD Services created a 3D MEP model in Revit with LOD 400 and clash-detection reports.

The quality deliverables helped the client with:

2D drawings or sketches that are converted into information-rich 3D BIM models and stored on cloud-based platforms serve as a single source of truth for multiple stakeholders. Design modifications, supported by parametric details, ensure that changes are seamlessly reflected throughout the entire model. Contractors and other stakeholders have continuous access to updated project data, ensuring accuracy and efficiency.

Collaborative processes during the design stage reduce RFIs and minimize change orders during the fabrication and installation phases, thereby reducing the need for rework. Reviewing quantity variances and validating change orders through better insights and change control optimize resources and project costs.

83% of project owners feel contractors should collaborate with them.– KPMG

Increased collaboration with 3D BIM model enables 30-35% cost savings for a hospital in Egypt

MEP BIM Model in Revit

MEP BIM Model in Revit

An Egyptian construction company required a clash-free 3D coordinated BIM model for their healthcare facility. The team at Hitech CADD Services resolved inter-disciplinary coordination issues and created a clash-free 3D BIM model.

This helped increase collaboration and bring stakeholders on the same page. Using this model to analyze energy efficiency, the client saved 30 to 35% on project budget.

Read Complete Case Study »Coordinated and error-free BIM models pave the way for precise fabrication and IFC drawings, providing contractors with a streamlined process and minimizing rework. The generation of Clash-free shop drawings for HVAC, electrical, plumbing, and fire systems, encompassing structural elevations, beams, columns, cross-sections, floor plans, and more, further enhances the efficiency of the construction process.

Enriched with annotations and mark-ups, these drawings empower contractors to effectively communicate and simplify MEP layouts for components and equipment. A design free of conflicts ensures optimal installation of components and systems, reducing the need for extensive rework.

60% of general contractors face coordination and communication issues between team members leading to poor productivity.– Autodesk & Dodge Data & Analytics

Coordinated 3D BIM model reduces rework and saves time for a university hospital building

LOD 500 Modeling in Revit

LOD 500 Modeling in Revit

A coordinated BIM model for a university hospital building was required at LOD 500 for better scheduling and ROI. The team at Hitech CADD Services created a clash-free 3D model with accurate material takeoffs and project schedules.

This positively impacted client business by streamlining construction activities, reducing rework and saving on time.

Read Complete Case Study »A coordinated and clash-free 3D model augmented with the dimension of time (4D) can assist contractors with timely project completion. A precise and detailed graphical representation of the project timeline, incorporating the sequencing of equipment, materials, and resources, enhances logistics and minimizes material waste. Using 4D scheduling, contractors can navigate an upward trajectory, ensuring projects are completed on time and within budget.

Precise scheduling with 4D BIM enabled timely project completion for a mixed-use building

Architectural BIM Model

Architectural BIM Model

An architectural company required a 4D BIM model of a multi-storey mixed-use building in the UK. The team at Hitech CADD Services prepared a clash-free 3D model with 4D sequencing and scheduling.

The model enabled the client to complete the project on time by improving design communication with their end customers through sequential video.

Read Complete Case Study »Walkthroughs augmented with AR/VR capabilities empower contractors with a comprehensive visualization of architectural, structural, and MEP systems. The ability to interact with multiple building components in real-time ensures higher efficiency, visual model validation, and better constructability.

Incorporating construction simulations with a focus on phasing and logistics allows contractors to strategically plan and manage workflows. This ensures improved installation milestones and enhances onsite safety protocols, ensuring a more secure construction environment.

According to Autodesk® and Dodge Data and Analytics, 53% of large contracting companies are deploying software to manage inspections and safety on half of their projects.

Get 100% hassle-free installation of MEP components.

Contact our MEP modeling experts TODAY »Revit automation enriched with tools like Dynamo, APIs, and Macros is set to transform generative design for present-day complex construction. The capability to create and modify model prototypes with parametric design will simplify and boost processes and productivity. The presence of customized Revit content drives standardization across every project phase to build high-quality installation deliverables.

Optimized design performance through task automation, compliance, customized scripting, model uniformity, etc. will extend Revit capabilities to model, document, design, and detail complex systems. Quick conflict resolution will continue to filter out ambiguities in the preconstruction stage, while repetitive functions will be taken care of with Revit BIM automation using Dynamo.

Final Deliverables in Dynamo

Final Deliverables in Dynamo

Dynamo automation saves up to 50% time and up to 18% costs for a project with 100% accuracy to create hundreds of BIM models with precise construction documents.

Read Complete Case Study »Evaluating design parameters through automated generative design reflects changes on the existing design, energy load calculations, and construction budget. Integrated workflows reinforced with rule-based modeling help make informed decisions with multiple design prototypes.

70% of contractors believe advanced technology can improve productivity by 78%, enhance schedule by 75%, and improve safety by 79%.

The use of automated generative design draws faster project execution through automation of repetitive tasks, reduced errors and risks, and improved productivity through seamless workflow integration. Transforming the design process by codifying rules and objects, project goals, and libraries can help contractors build and leverage compliant and efficient designs.

There is a host of opportunities contractors can take advantage of with the use of BIM. The preconstruction stage being decisive to achieve effective and efficient fabrication and installation requires BIM to be deployed as early as possible.

With an intuitive 3D modeling process, contractors can convey exact client expectations through early flaw identification, precise schedules, risk management, and cost validation.

You may also like

Top 5 Global MEP BIM Outsourcing Companies

Top 5 Architectural BIM Companies to Outsource

Top 5 Sheet Metal Design Companies to Outsource