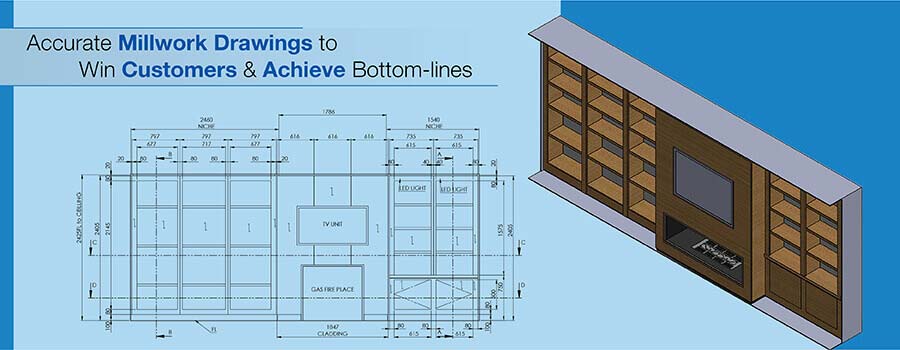

Millwork drawings are a critical component in the furniture manufacturing process which can potentially impact operational efficiencies. How you develop complete, accurate, and buildable millwork drawings are crucial to winning customers and achieving bottom-lines.

Furniture manufacturing, especially in the millwork space, has always remained sensitive to price fluctuations, customer demands, and a fiercely competitive environment. Amidst this competition and instability, furniture manufacturers need to even deal with skill gaps without compromising on efficiency.

While investing in the augmentation of fabrication and woodworking capabilities might sound a right step forward, millwork furniture manufacturers need to give a fresh look to their existing design processes and technologies. They need to strengthen the process of developing the millwork shop drawings to help to fabricate the finished product – documents that form a single source of truth to communicate the concept. Many times, CAD engineers also create comprehensive 3D CAD models created to suite the CNC machine needs on the factory floor as well. Select the appropriate manufacturing processes, determine the inconsistencies, and eventually turn that concept into a tangible furniture item.

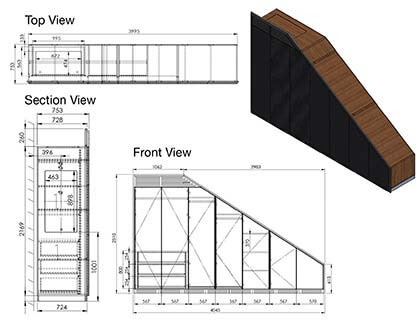

One of the important roles of millwork drawings is perhaps to identify and finalize the design requirements right from the early product development stages. From detailed dimensions, and material used to manufacturing information, millwork shop drawings take the guesswork out of the equation and give designers the clarity on how their designed furniture piece will look and fit within the given space.

With complete and accurate details, millwork drawings hold the key to faster project approval from the designer, allowing you to shorten the manufacturing lead time significantly. CAD tools such as AutoCAD®, Inventor® or SolidWorks help create detailed shop drawings for millwork to accurately convey design intent on the shop floor.

A clear set of millwork drawings will also bring more clarity on the customer expectations, as they include a specific level of real-world buildable fabrication and installation detail, often not represented on the architectural drawings.

Millwork drawings reduced cycle times by 25% for a bespoke joinery manufacturer

A UK-based specialist joinery manufacturer partnered with Hitech to improve operational efficiencies and bring down manufacturing costs while delivering bespoke joinery to their customers.

With extensive experience and knowledge of veneer selection, material choices, and joinery construction, engineers at Hitech delivered accurate working drawings against architectural drawings and hand sketches. These drawings improved the design communication during manufacturing and installation, resulting in significant savings in terms of time and cost.

The knowledge transfer further led to improvements across material selection, design, and project management processes, bringing 25% reduction in overall cycle time.

Read Complete Case Study →

Millwork drawings essentially bring the furniture design concepts to reality by transforming the designer’s concept to manufacturing-ready drawings. It is through these documents that you get an opportunity to comprehend and finalize the approach by substituting materials and products that provide the same design intent and quality as perceived by the designer.

Preliminary shop drawings during design development offer a way to identify constraints and limitations. Furthermore, they follow a specific set of design standards and specifications such as AWI, ASME, TEMA, etc. which makes it easier to get approvals from the designer and various stakeholders before moving to actual manufacturing. Having clarity on every aspect allows your factory floor to remain efficient, and improvements here will have a direct influence on the bottom line.

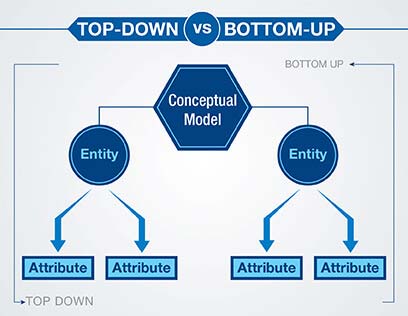

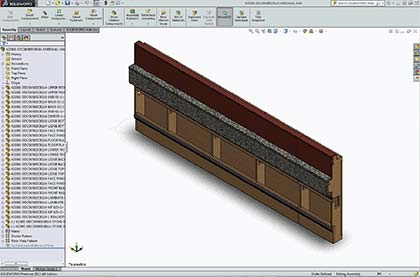

Millwork drawings derived using 3D parametric models from tools like SolidWorks further offer an opportunity to improve the top-down or in-context assembly design. This extremely beneficial for millwork items like cabinets, where an outer skeleton model once created will resize all of its components automatically. This change in the size of the cabinet will automatically update the millwork drawings, without requiring any manual rework. Such CAD feature helps you as a furniture manufacturer to reduce design cycles and bring your products to market faster.

Despite the popularity of 3D CAD, shop floor still heavily relies on 2D drawings. An experience of Europe based custom manufacturer best describes the advantages. When they switched to SolidWorks 3D, designer engineers were able to do in-context or top-down design. This approach gave designers better control over dimensional information in sub-assemblies and allowed quick changes. Compared to the traditional bottom-up approach, the manufacturer experienced 20% reduction in the manufacturing lead time.

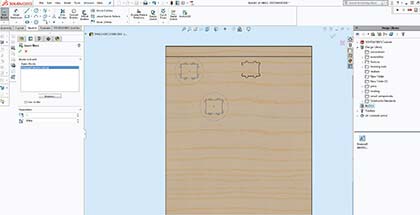

The design and development of a custom furniture piece is a time-intensive task. Your draftsmen may end up spending hours creating a custom furniture design from scratch. However, with parametric CAD tools like SolidWorks, you have access to a library of parts that can be reused in the design or can work as a guide to build custom designs using them.

A CAD library also saves you a lot of time by letting you import standard parts such as bolts, nuts, hinges, handles, etc. into your design directly rather than redrawing each item from scratch. Maintaining part libraries for not only saves time by expediting design cycle times but saves time and money to hire a CAD engineer every time a model is to be created.

Davis Furniture Industries, Inc., a leading manufacturer of contemporary office furniture, utilized the parametric nature of SolidWorks to design high-end furniture quickly. Utilizing the part library and configuration feature, Davis Furniture was able to cut design cycles by 75% and reduce the time-to-market by 50 percent.

One of the major advantages of utilizing a parametric CAD tool for millwork design requirements comes in the form of the ability to automate mundane and repetitive tasks such as preparing 2D submittal drawings. Traditionally, you’ll find yourself doing the same tasks of aligning the section views, dimensions, product notes, and other annotations to maintain consistency in your submittals. However, a CAD platform with automation capabilities eliminates the repetitive operations in the drafting process, allowing you to push your custom furniture design-to-manufacturing faster.

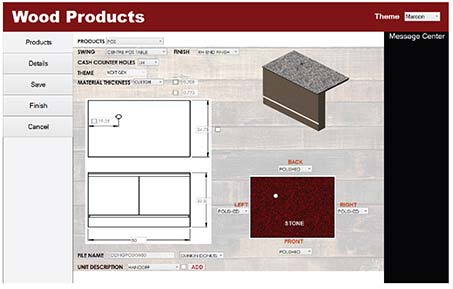

DriveWorks is one such tool that helps you automate repetitive design tasks and implement product configurators to accelerate design time while reducing errors. The tool essentially lets you create a rule-based design for your furniture pieces.

This means modifying any design element will automatically change the associated elements. Furthermore, you allow your customers to configure their pieces from the design palate offered with a guided sequence and a real-time 3D model.

The configuration so selected will also reflect on millwork drawings, providing you better accuracy and control in manufacturing through customized BOMs. Design automation API and CAD customization through macros are among the other ways to run automation scripts on your design files.

Hitech worked with a leading furniture manufacturer in the USA to automate their furniture design process, quotation, and documentation using SolidWorks and DriveWorks. The implementation of design automation resulted in a 70 times faster design cycle and a reduction of one week in time-to-market.

Read Complete Case Study →

Millwork drawings essentially reflect your understanding of the designer’s idea and form an important document that can be used to identify discrepancies between the customer requirements, the designer’s concept, and manufacturing feasibility. Virtual simulation of 3D CAD models during primary design analysis can generate animated videos that will give insights about design collision to the designer.

When the design is unclear, you can always use these shop drawings to get clarity from the designer, ask customers about their quality expectations. Better still, you can communicate effectively with vendors on materials, pricing, specifications, and real-world limitations.

As a furniture manufacturer, your goal is to offer your end customer’s high-quality, custom furniture items quickly; items that accurately resemble the designer’s intent. While investing in augmenting your manufacturing capabilities is essential to achieve this, millwork drawings are a major factor that can make or break your furniture manufacturing efficiency.

Millwork drawing detailed with all manufacturing information, GD&Ts, etc. is what ultimately determines the overall success of your project. From being a document that communicates the designer’s idea to a clear set of instructions for accurate manufacturing, millwork drawings get the job done quickly. And, with the intuitive 3D parametric CAD tools, developing these design documents is a whole lot easier with an added advantage of automating repetitive tasks and the power of 3D visual communication with all the stakeholders.

Altogether, these improvements directly boost your factory floor efficiencies by effectively communicating design intent to shop floor and reducing change orders or material waste. It thus helps you achieve your manufacturing goals effectively.

You may also like

Top 5 Global MEP BIM Outsourcing Companies

Top 5 Architectural BIM Companies to Outsource

Top 5 Sheet Metal Design Companies to Outsource