Business Needs

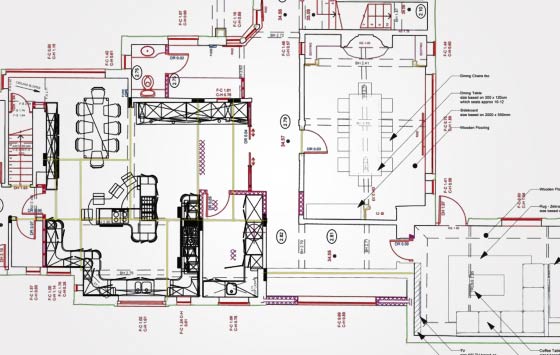

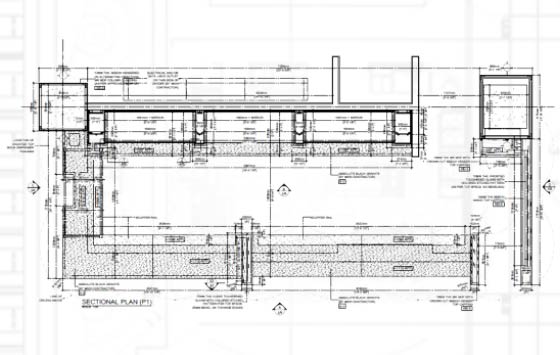

The joinery manufacturer and supplier needed to develop a standard millwork drawing procedure for every project team members by elevating information flow requests. Further, they also needed insights on how bespoke joinery could be structurally integrated seamlessly into the office building system.

Challenges

Delivered accurate millwork and joinery drawings to improve the design communication during manufacturing, resulting in significant savings in terms of time and cost.

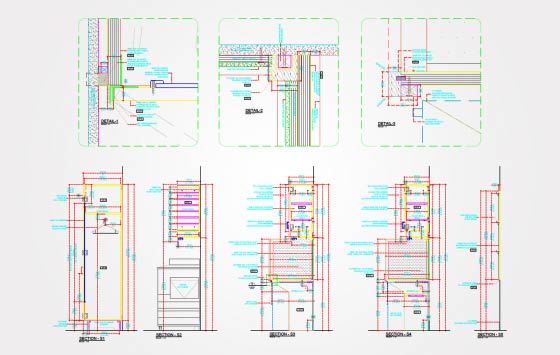

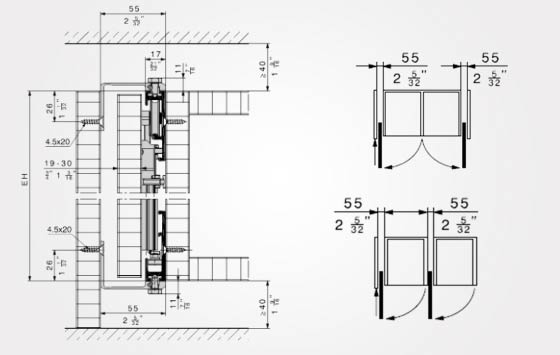

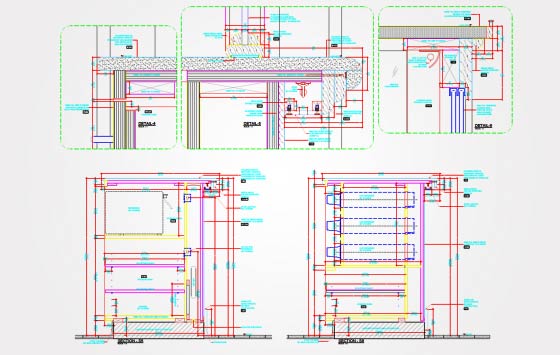

Project engineers studied the architectural drawings and hand sketches shared by the client to understand the function of joinery. Second critical task was to assign proper dimensions to joinery and bespoke furniture according to the veneer selection, material choices and depicting it all on drawings.

The partnership resulted in developing library blocks and detailed fit to assembly drawings for bespoke benches, architectural joinery, working instruction of door sets, sliding sash windows, units, fitments, paneling/cladding, and joinery products.

The client could establish a standard work procedure for bespoke furniture design development, manufacturing drawings preparation and production. The streamlined approach led to achieve reduction in overcasts and facilitated the information between stakeholders and solved queries, saving 25% of the time.