Business Needs

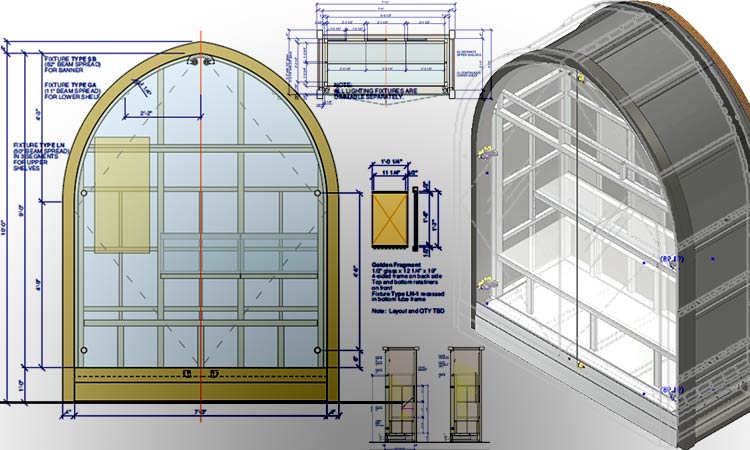

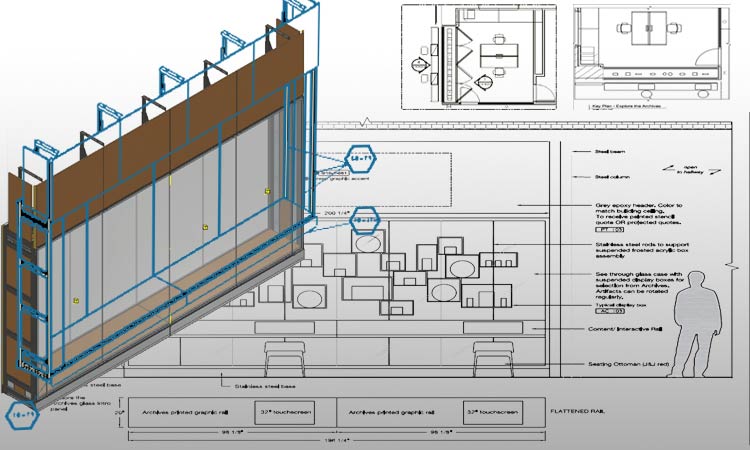

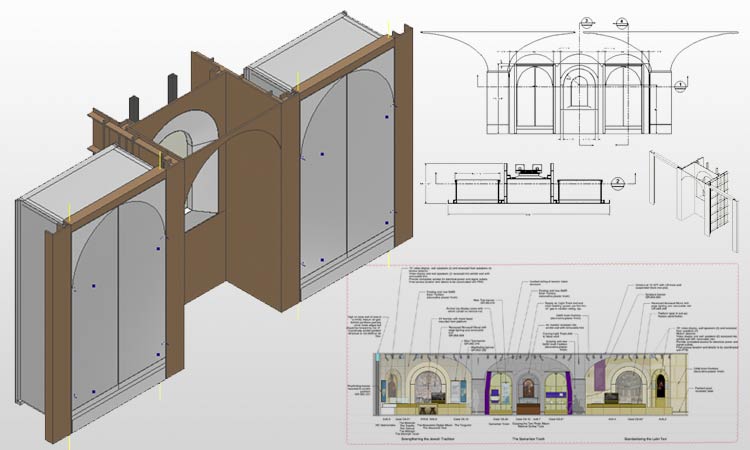

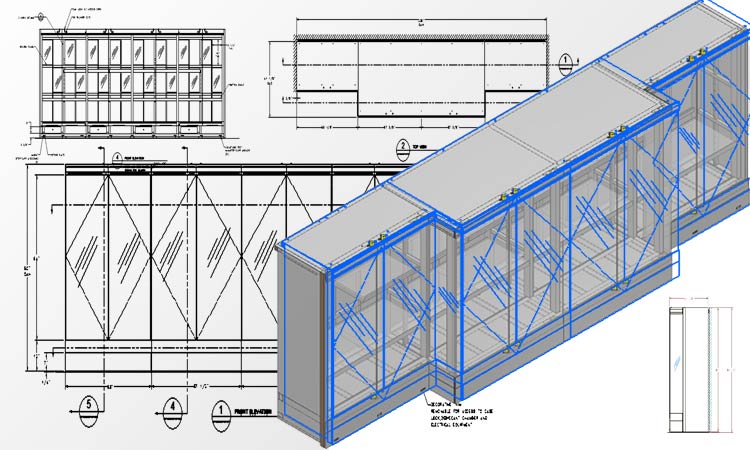

The client needed precision millwork shop drawings to communicate right design intent on shop floor owing to historical architectural design of museum. Also, since the furniture had multiple components to be modeled, client wanted an efficient solution with quick turnaround times using their online CAD Vault systems.

Challenges

Achieved zero reworks for institutional millwork with CAD shop drawings, assembly, and installation guides, resulting in high quality and faster turnaround times.

Project engineers studied the architectural drawings and hand sketches shared by the client to understand fitting of various joineries across the museum. Based on our prior experience in millwork and casework drafting, we suggested veneer selection and material choices for various fit outs and then started developing CAD drawings.

The project engineers delivered high-quality manufacturing drawings with detailed joinery and installation instruction guide. These drawings assisted foremen on site and lead elimination of interruptions during installation.

With the accuracy of manufacturing and precision in installation guides, the client could completely eliminate any rework. Any need for size adjustments back on shop floor once the products were dispatched on site was eradicated with synchronized communication between teams. Also, client could significantly reduce turnaround times and achieve high-quality outputs using vaults and replicating models.