Challenges

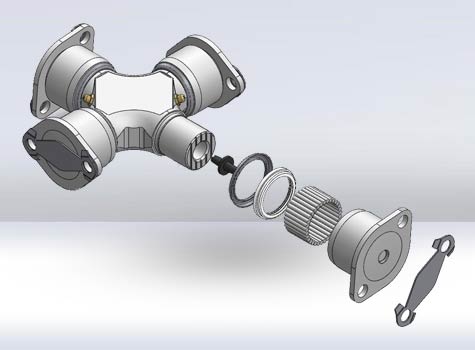

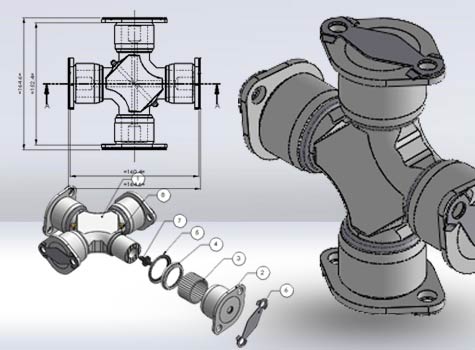

Examined the scope of reverse engineering at the beginning of the project. 3D CAD models and manufacturing drawings helped to identify the areas that needed design alteration with ease.

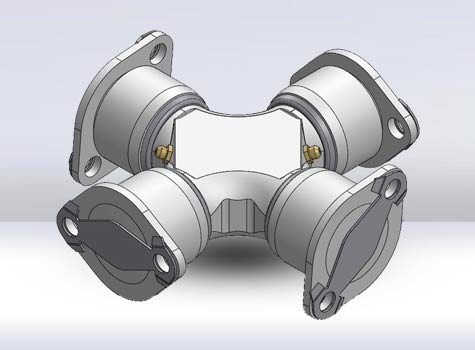

Automotive Industry has components that have been in existence since pre-CAD era and extreme exposure to wear and tear has caused them to be worn out. For the client, auto parts manufacturer, it was the exact situation when we partnered with him to reverse engineer the parts and re-create 3D CAD geometry.

Final 3D CAD models and manufacturing drawings with quick design changes were shared with the client with them the manufacturer could recreate the parts. Reverse engineering process helped identifying the areas that needed design alteration with ease.