Retail store layouts and fittings need to multitask and fit accurately without leaving alcoves to enhance user experience as well as address furniture flexibility. It demands close collaboration between designers and manufacturers.

Challenges in shopfitting design & manufacturing

CAD overcomes the challenges

The increasing need for compact store spaces has raised the demand for multifunctional shopfitting furniture. Additionally, shop layouts of local shops, brand stores or hypermarkets – they all undergo constant restructuring for better customer experience. Thus, shopfitting furniture has to be flexible enough to move around and modular for easy fix after dismantling for relocation across the shop.

Store owners’ preference for thematic and bespoke furniture designs for higher customer satisfaction is iterative and prone to inaccuracies that lead to further manufacturing process disruptions.

The root cause of all iterations and dynamism in the shopfitting design process is the involvement of multiple design stakeholders – architects, industrial design engineers and manufacturers.

CAD establishes a consortium between architects, the industrial design engineer and the manufacturer that bridges the gaps between fixture aesthetics and engineering concepts. CAD generates federated 3D CAD models and 2D manufacturing drawings for change approvals before the production starts.

Today, what manufacturers need is precision to ensure that the final deliverables fit in well without leaving smalls slits between furniture and the frame or wall. Here as well, if designers have delivered assembly and installation drawings in accordance with the architectural floor plan, the quality of the final deliverables will be maintained.

Investment in CAD for shopfitting might seem like a leisure spending for local store owners, but that is the principal stage to achieve elite and finely engineered shop fit-outs, joineries, and fixtures.

“A good CAD drawing closely aligns the design instruction with the manufacturer’s tooling capability but a great CAD drawing makes them indivisible.”

Given the growing competition, retail stores no more compete with neighborhood shops or a brand next door. Their major competitors are online stores – a bigger threat. In the UK alone, e-stores account for more than 10% point of sales. In this situation, offering ergonomic experience and an elite interface – shopfitting to customers is a smart move.

Keeping customer centric facilities in focus, store spaces are redesigned at regular intervals to keep up with the trends. The process might not necessarily need any major architectural changes; a lot of shop layout revamping lies in adjusting the designs of existing fit-outs, casework, millwork and furniture to contemporary designs patterns.

Retail furniture manufacturer reduces 45% costs with detailed CAD drawings

A 30 year old UK based retail furniture manufacturer was reconstructing fitting room of a prominent retail store chain. The biggest challenge was to interpret design intent in readily available concept sketches and develop geometrically accurate manufacturing drawings for enhanced manufacturability.

Hitech CAD engineers partnered with the designer to develop drawings that went from design engineers to shop floor and back to design engineers to finalize production drawings. A set of manufacturing drawings, packing and unpacking information for transit, assembly drawings and installation guides were also shipped to the client that led to reduction in 45% of the costs during transportation, 70% shorter design cycle and 60% design reduction costs due to offshoring.

Read Complete Case Study →All these can be a quick finish task if the design produces site drawings to scale and layout for already existing furniture to facilitate quick manufacturing. CAD drawings give insights to the designers when reworking on the fit-outs or new furniture that complements the existing ones. They not only give a comprehensive idea about complete layout but also establish better coordination between architects, space owner, the industrial design engineer, manufacturer and the shopfitter.

Because at some point, a small change in one specification of a shoe display rack (for example) often leads to multiple alterations across the rack geometrical measurements. In such situations, CAD design database comes to the rescue in faster decision making. Also, even if the designs are to be developed from scratch and manufactured CAD drawings give them an opportunity to maintain quality and develop final form and finish according to the existing furniture.

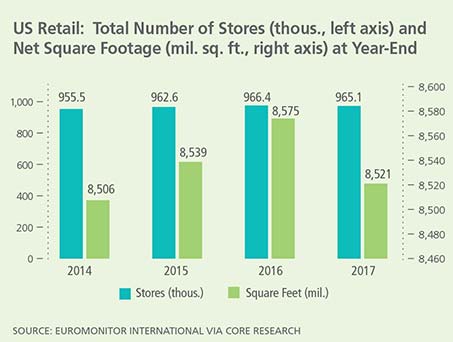

Shop fits-outs that are engineered for modularity, flexibility, and interactivity are in demand for brands to compete in the market. Many times store owners show 3D data of the store rooms and spaces to help designer plan the layout accurately. It is a well-known fact that retail spaces are shrinking. Inch by inch, shops become smaller while number by number, merchandise variety grows larger. The graph below gives an insight into the changing store space patters across the US. This area is further compacted slowly.

Under such circumstances, shop owners seek furniture sets that perform multi-tasks and can be adjusted as per the need without much expertise. As a result, the retailers need furniture suppliers to get innovative solutions to maximize space utilization including aspects such as modularity, flexibility, etc. Industrial furniture designers and CAD drafters are valuable resources to create right CAD drawings for bespoke joinery setting out on site.

As per Gartner,“Retail space management is composed of three major elements of macrospace planning, microspace planning and visual merchandising. Space optimization may be an additional element. Microspace planning is the assignment of specific products to fixtures and their resulting placement on shelving, pegs or other structures, based on a set of performance parameters.”

Industrial design engineers develop compact designs for modular shop fit-outs that can be manufactured remotely, transported safely and assembled and installed at the site. Furthermore, on your shop floor, whether you have laminating press or edge bander, fabrication shop drawings for each is different with varying set of manufacturing instructions.

In such a scenario, CAD engineering documents work as sequential instruction guide through installation drawings and videos. It’ll not only help the foremen to install accurately but also minimize reworks, and make the process safer, even for smaller shop sizes.

Retail store manufacturer saves material by optimizing sheet metal thickness

One of our esteemed clients, a retail store furniture manufacturer from the Europe, had a major project of developing store fixtures for a leading brand in the retail industry. The store owner was looking for two alternatives of existing designs to be able to adjust the fixtures as per the changing floor space availability.

A team of 12 project engineers developed CAD models based on the pictures of the existing designs using CAD drafting and 3D scan converters techniques. The team discovered that the current material for racks used 5 mm aluminum sheet metal which was reduced to 1.5 mm. The new designs were tested with CAE tools in several aspects to ensure the safe operations. Further, a detachable part was developed at the frames which allowed the manufacturer to change the positioning from floor mounting to wall mounting simply by screwing and un-screwing the parts and fixtures.

Source: Holzformart

Source: Holzformart

When shop fixtures, furniture and rest of shop interior are in harmony, they give a look of uniformity bringing back the customers irrespective of how old the brand is. For example, designing rack and shelving systems with right surface finish, veneer selection, colors, and joineries that complement brand furniture, it boosts brand identity and theme. Additionally, they help customers in better maneuvering across the store with strategically placed merchandise to leverage up-selling for higher sales and profitability.

3D solid CAD models of the shop fit-outs when rendered with appropriate rendering tools like 3ds Max® or Photoshop® emphasizes on the physical properties of the product such as surface finish, material, dents, shadows etc. It gives decision makers a realistic choice to choose from and the manufacturers can use them for marketing brochures and catalogues.

Sports article manufacturer brings brand essence to store with shop fit-outs

Source: Holzformart

Source: Holzformart

Adidas, the German sports equipment manufacturer, with right shop-fitting choice successfully staged a range of their special edition watches. The central idea to design the furniture was to convey the brand image of durability and sports performance.

To depict these two characteristics, two unusual contrasting materials were used for the display racks – glass and metal with an offset by the natural appeal of wooden surfaces.

The sports brand could easily install them on site to display the watches with to attract more customers. Also, the two contradicting material – metal with ductile characteristics and glass with brittle properties – attracted more eyes and eventually higher brand recognition.

CAD platforms give a good start to the designer in converting the concept sketches to detailed 3D models with meticulously assigned geometrical details. All the models and engineering designs are approved by all design stakeholders. Thus, manufacturing drawings will be in alignment with custom tooling capability of the manufacturer which eliminates ECOs and synchronizes manufacturing with design.

You may also like

Top 5 Global MEP BIM Outsourcing Companies

Top 5 Architectural BIM Companies to Outsource

Top 5 Sheet Metal Design Companies to Outsource