Expert CAD drafting plays a crucial role in making woodworking profitable by enhancing precision, efficiency, and creativity, resulting in cost savings and improved quality. The synergy of expert CAD drafting and advanced CAD tools is a game-changer in woodworking.

Table of Content

CAD for custom woodworking design has resulted in substantial cost savings and has become a preferred choice for millworkers and furniture manufacturing companies. It has not only streamlined the manufacturing processes but has also opened new avenues for custom design and craftsmanship.

A CAD drafting expert comes with years of experience in 3D CAD for woodworking. Hence can deliver accurate joinery drawings, cabinet drawings and other manufacturing drawings for a range of products. With their expertise they not only help with woodworking design using CAD, but also material optimization in CAD.

Using parametric CAD platforms in woodworking provides an array of benefits that enhance the way woodworkers approach their design development. Here are some of the key advantages:

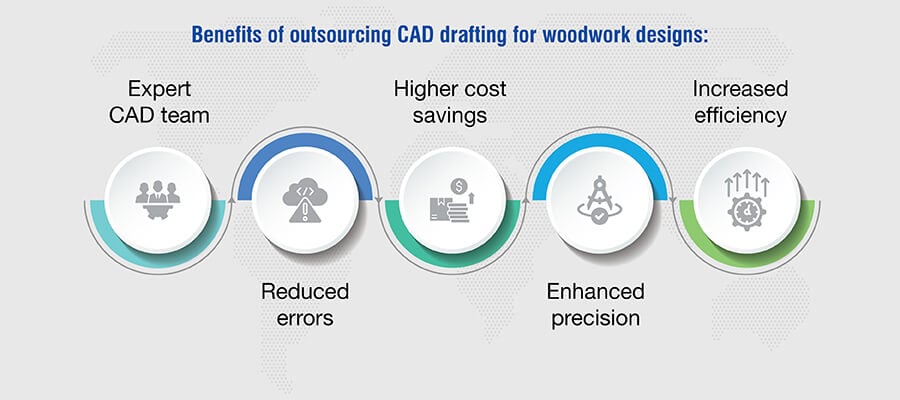

Woodworking is a field that combines creativity with precision. In today’s competitive market, it is crucial to leverage technology to deliver the best possible products. Expert CAD drafting brings a multitude of benefits to the woodworking industry, enhancing the quality, efficiency, and profitability of the projects.

The complexity and detail involved in woodworking projects require a deep understanding of both the craft and the software tools. Expert CAD drafters for woodworking bring years of experience and specialized knowledge, ensuring that the designs are accurate, practical, and aesthetically pleasing. They can interpret the vision of the client or designer and translate it into a detailed and precise CAD model.

In woodworking, precision is everything. Small mistakes can lead to misaligned joints, ill-fitting parts, and ultimately a compromised final product. Expert CAD drafters utilize advanced software tools and their in-depth knowledge to minimize errors. They can foresee potential issues and rectify them in the design stage, preventing costly mistakes and streamlining woodworking process.

Hiring a CAD expert for woodworking CAD drafting results in significant cost savings by minimizing material waste through precise and accurate drawings, reducing project timelines and associated labor costs, preventing expensive design errors, and optimizing designs for cost-effective manufacturing. This investment in professional CAD drafting services ensures efficiency and accuracy, ultimately cost saving in woodworking and contributing to the overall success of the project.

Every woodworking project is unique, and clients often have specific requirements. Expert CAD drafters can provide highly customized designs, tailored to meet the unique needs of each project. They can create intricate and complex designs with precision, ensuring that the final product meets the client’s expectations.

Expert CAD drafters utilize the latest technology and software tools, which significantly increase efficiency and productivity, enhancing woodwork design efficiency. They can quickly make changes and iterations in the design, facilitating better collaboration and communication among the team. This streamlined process allows for faster project completion and the ability to take on more projects, ultimately increasing the revenue of the woodworking business.

Woodworking Success Starts with Expert CAD Drafting

Reach Out NowWhile getting started with woodwork CAD drafting can seem to be a daunting task, some checks can help.

Several CAD software options are highly popular and effective for woodworking drawings. Some of the most recommended choices include AutoCAD, SolidWorks, and Inventor. All these programs offer a range of features tailored to the specific needs of woodworking projects, allowing you to create detailed and accurate designs.

Before settling on a specific CAD program, consider the following factors:

When it comes to CAD software for woodworking, specialized plugins can greatly enhance the design and manufacturing process. The two most prominent plugins are SWOOD and WoodWork for Inventor, which seamlessly integrate with all popular CAD platforms to deliver a range of features tailored to woodworking.

SWOOD:

SWOOD enhances woodworking design by integrating seamlessly with SOLIDWORKS, providing a tailored suite of tools for precision crafting of furniture and wooden structures. Its extensive library of parametric components streamlines the addition of drawers, doors, and panels, while advanced features like CNC integration optimize the journey from design to manufacturing. With an intuitive interface and comprehensive features, SWOOD stands out as a top choice for woodworkers embracing CAD.

WoodWork for Inventor:

WoodWork for Inventor boosts Autodesk Inventor, offering a specialized suite of features including a comprehensive material library, automated part generation, and tools for crafting joints and other elements. This plugin empowers users to intricately design and visualize projects, ensuring perfection before manufacturing. With CNC integration and a user-friendly interface, WoodWork for Inventor is a go-to for woodworkers using Autodesk Inventor.

Basic thumb rule is that a super quarterback for one NFL team may not play well for another NFL team; until he gets to know other players, follow this rule religiously. Check out a few CAD drafting service providers for woodworking to see what looks good. Doing a few small jobs together to check out if smoothening of details and format issues along with due dates and pricing; is not at all a bad idea.

Also verify:

Integrating expert CAD drafting into the woodworking design drafting is a strategic move that significantly boosts profitability. By leveraging the precision, efficiency, and creative freedom offered by CAD software, woodworkers can elevate the quality of their products, reduce costly mistakes, and optimize their workflow.

Furthermore, expert CAD drafters bring a wealth of experience and technical skill to the table, ensuring that every design is not only beautiful but also practical and cost-effective. The synergy of expert drafting and advanced CAD tools is a game-changer in woodworking, ultimately leading to higher customer satisfaction, repeat business, and a stronger bottom line.

You may also like

DXF Files in SolidWorks: How to Import and Export Them

Architectural Design Process: Exploring the 8 Phases

Sheet Metal Bending in SolidWorks:The Ultimate Guide [2024]