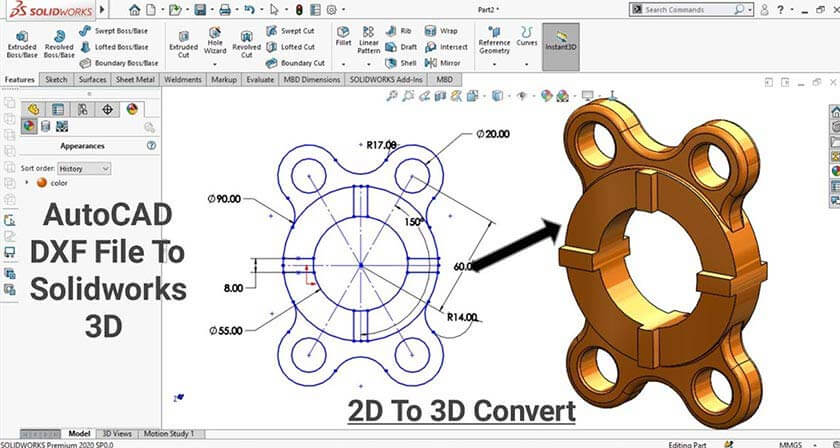

DXF files, developed by Autodesk, ensure seamless data exchange between CAD programs like AutoCAD and SolidWorks. They maintain design integrity, crucial for collaborative projects in manufacturing, architecture, and engineering.

Table of Contents

Modern CAD tools have become an integral part of the manufacturing industry, especially for custom and discrete manufacturers. While DWG files and 3D models are prominent, DXF files hold significant importance.

Developed by Autodesk, DXF files facilitate data interoperability between AutoCAD and other CAD programs, making them crucial in collaborative environments. Let’s understand the usage of DXF files in SolidWorks, common issues and solutions, and best practices in different manufacturing contexts.

DXF files are a type of CAD file format developed by Autodesk to enable the exchange of drawing data between AutoCAD and other programs. They serve as bridges, allowing different CAD software to communicate and share designs seamlessly. This interoperability is vital in collaborative projects, where different teams might use various CAD tools. For instance, a design team might use AutoCAD, while a manufacturing team might rely on SolidWorks. DXF files ensure that both teams can share and interpret the design data accurately.

The primary advantage of DXF files lies in their ability to maintain the integrity of the original design. They preserve all geometric data, layers, line types, and other essential information, ensuring that the design remains consistent across different platforms. This feature is particularly important in industries such as architecture, engineering, and manufacturing, where precision and accuracy are paramount.

Importing DXF files into SolidWorks is a straightforward process, but it requires some preparation to ensure the integrity of imported data. Here’s a step-by-step guide:

Before importing a DXF file into SolidWorks, it’s crucial to clean the file and ensure it contains only the necessary geometry. Removing unnecessary elements helps prevent errors during the import process.

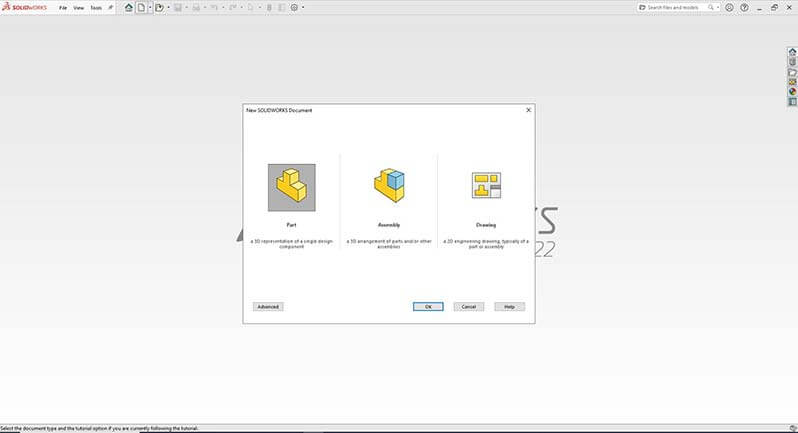

Open SolidWorks and Create a New Sketch: Start by opening SolidWorks and creating a new sketch where the DXF data will be imported.

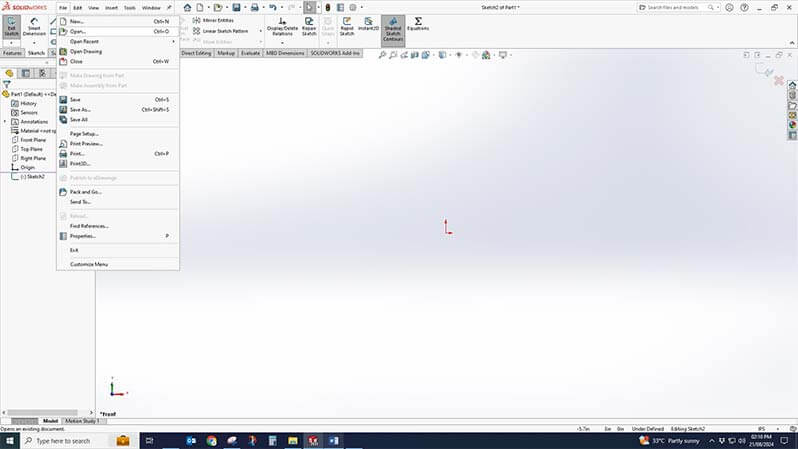

Select File › Open: Navigate to the ‘File’ menu, select ‘Open,’ choose the DXF file, and click ‘Open.’

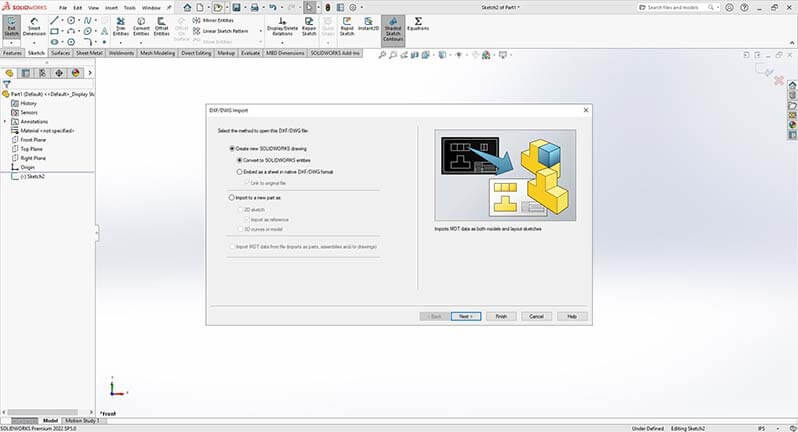

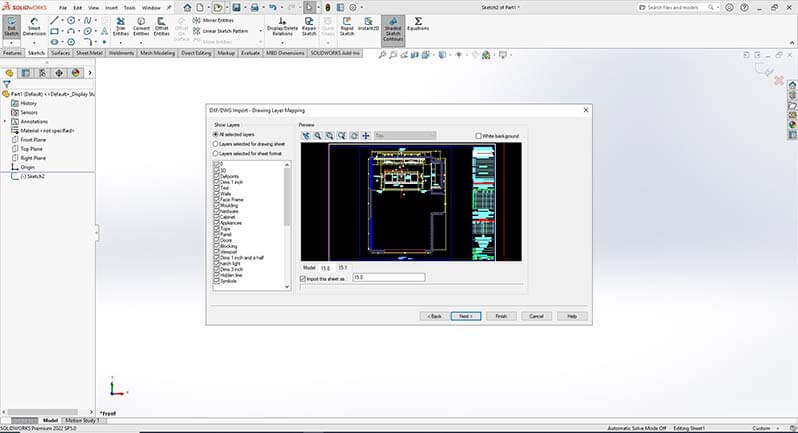

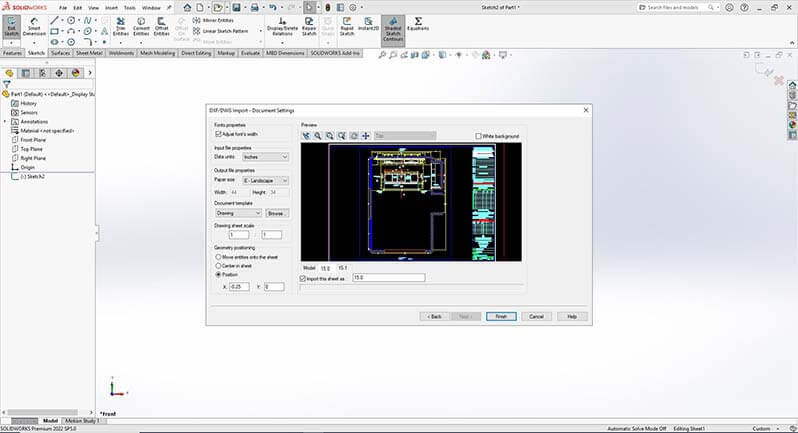

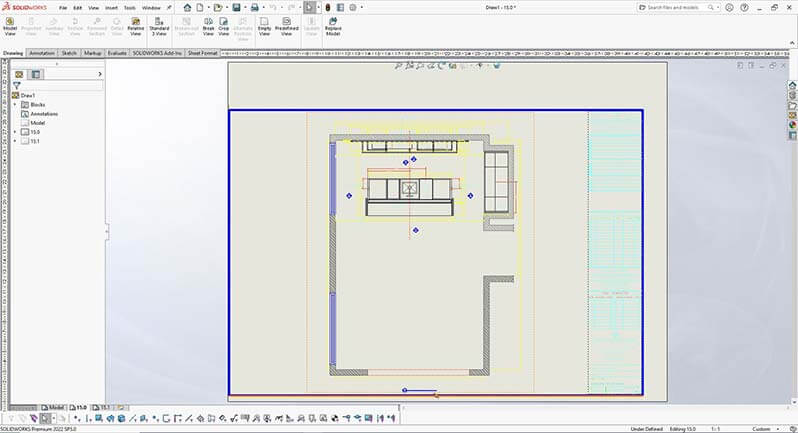

Use the DXF/DWG Import Wizard: SolidWorks will launch the DXF/DWG Import Wizard. Choose whether to import the file as a 2D sketch, 3D curves, or a 3D model.

Map DXF Layers to SolidWorks Sketch Entities: The wizard will prompt you to map DXF layers to SolidWorks sketch entities. This step is crucial for maintaining the structure of imported data.

Review and Clean Up: Once the file is imported, review the sketch and clean up any issues to ensure accuracy.

Upgrade your designs with professional 2D to 3D CAD conversion.

Contact Our Experts »Exporting DXF files from SolidWorks is essential for sharing designs with teams using different CAD software. Here’s how to do it:

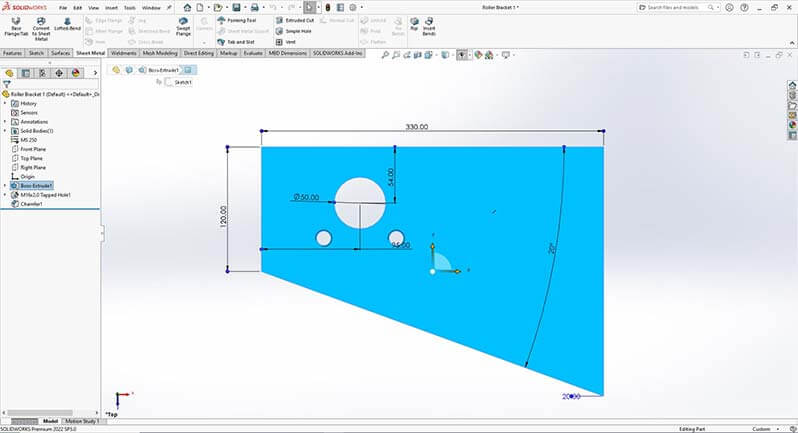

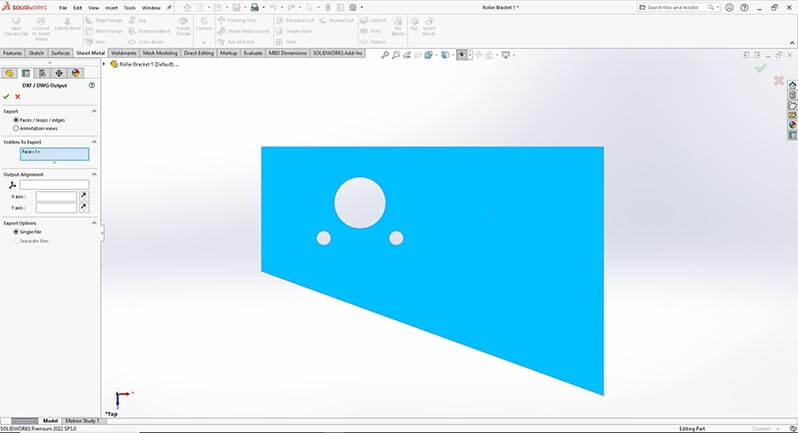

Create or Open the Part/Assembly: Start by creating or opening the part or assembly you want to export.

Select the Face or Flat Pattern: Choose the face or flat pattern of the part to be exported.

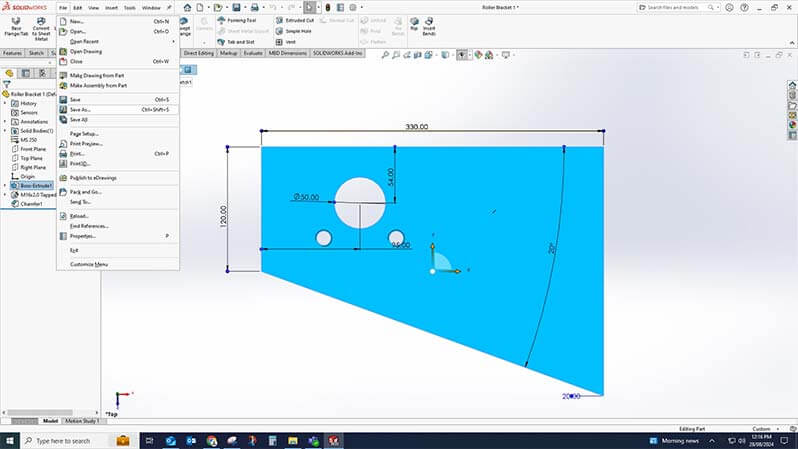

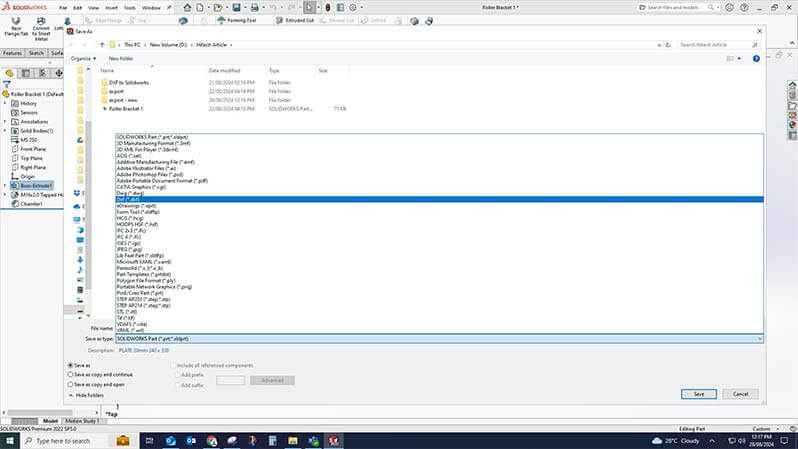

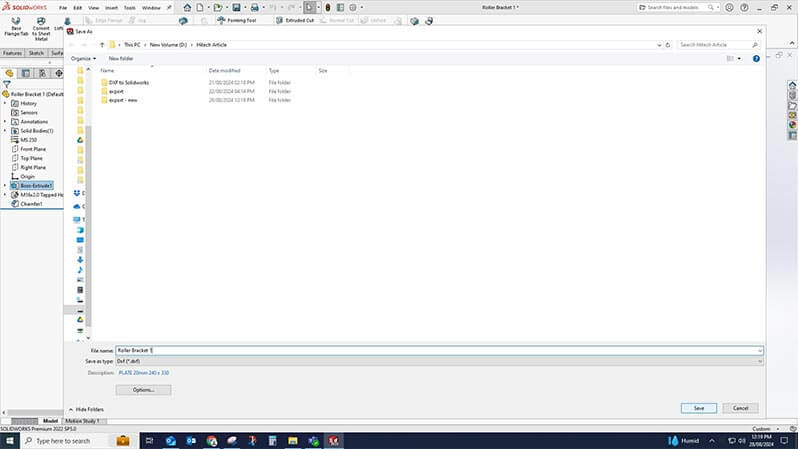

Go to File › Save As: In the ‘File’ menu, select ‘Save As’ and choose DXF (*.dxf) from the file type dropdown.

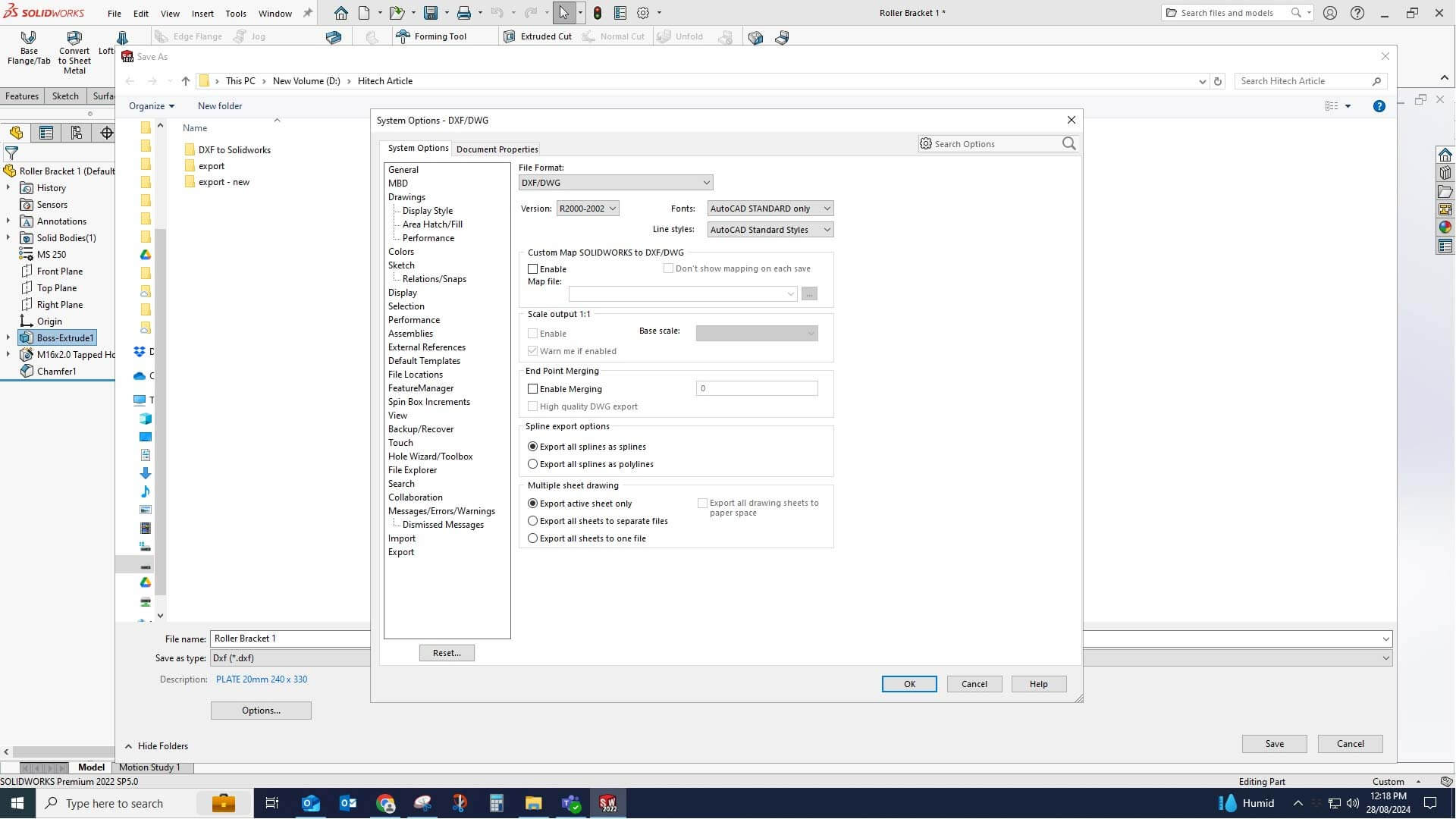

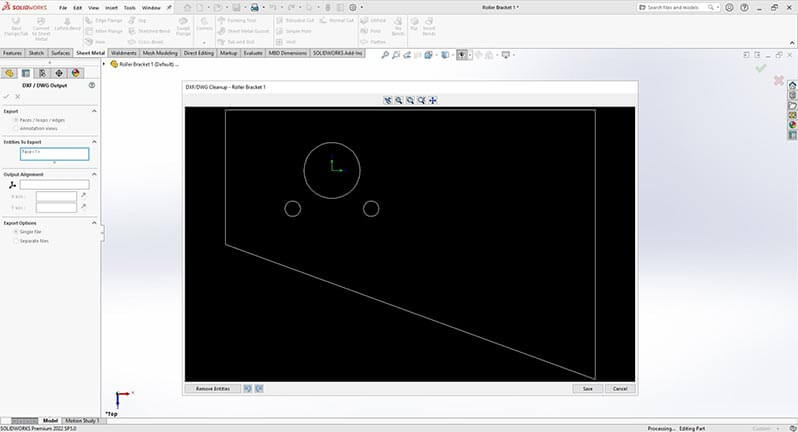

Configure Export Options: In the Export Options dialog, configure settings, such as output version and geometry options.

Save and Review: Click ‘Save’ and review the preview to ensure the exported DXF file is correct.

Working with DXF files can sometimes lead to issues. Here are some common problems and their solutions:

Issues:

Solutions:

Need precise concept designs? Let us draft them for you.

Get in touch today »To optimize your experience while using DXF files in SolidWorks consider the following practices. You’ll improve efficiency, enhance design robustness, and streamline collaboration.

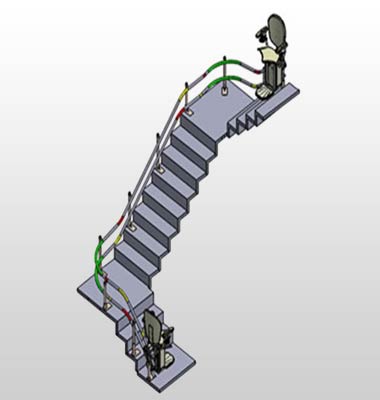

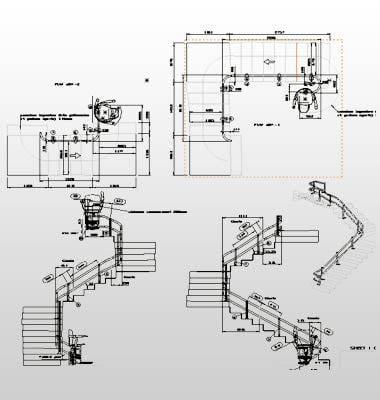

3D Modeling & Fabrication Drawing for Stairlifts Manufacturer, Europe

Hitech CADD Services streamlined the design process for a European stairlift manufacturer by integrating SolidWorks with AutoCAD, enabling seamless interoperability. AutoCAD drawings provided by the client were customized to align with multiple international standards. The team used SolidWorks APIs to ensure accurate migration of design data, maintaining essential functionalities. This integration allowed for rapid 3D modeling and fabrication drawing generation, significantly reducing design time, and improving production accuracy.

Stairlift 3D Model

Stairlift 3D Model

Manufacturing Drawings

Manufacturing Drawings

Using DXF files efficiently in SolidWorks requires adhering to best practices tailored to specific manufacturing contexts. This ensures that designs are accurately interpreted and manufactured, reducing errors and improving the overall quality of the final product. Here are some guidelines for different industries:

Furniture manufacturing often involves complex designs with multiple components that need to fit together perfectly. To achieve this, the following practices are essential:

Millwork involves detailed woodwork and cabinetry, requiring precise cuts and fits. The following best practices help ensure accuracy and efficiency:

Metal fabrication involves working with materials like steel, aluminum, and other metals to create parts and structures. Here are some best practices for using DXF files in this context:

By following these guidelines, you can effectively use DXF files in SolidWorks, enhancing your design workflow and ensuring seamless collaboration across different CAD platforms.

DXF files play a pivotal role in CAD design, enabling seamless data exchange between different software programs. Understanding how to import and export DXF files in SolidWorks, address common issues, and adhere to best practices can significantly enhance your design and manufacturing processes. Whether you’re in furniture manufacturing, millwork, or metal fabrication, mastering the use of DXF files will help you achieve precision and efficiency in your projects.

You may also like

From 2D to 3D: Why Architects are Switching to BIM Modeling