Accurate HVAC ductwork design is crucial for optimal air distribution, energy use, minimal pressure loss, balanced static pressure, and occupant well-being. A well-planned HVAC layout and precise duct sizing significantly enhance energy efficiency, reduce noise levels, and improve indoor air quality.

Table of Contents

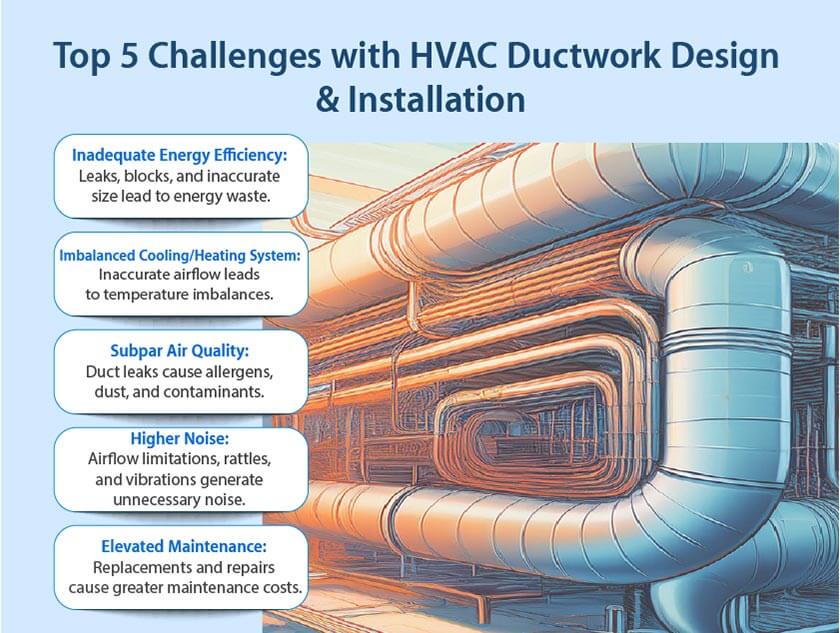

Poorly designed HVAC systems with errors in ductwork installation can lead to uneven temperatures, inefficient operations, excessive noise levels, and higher energy bills. However, the dense network of HVAC ducts, made of fiberglass, sheet metal, or flexible plastic, presents design complexities that require precise ductwork layout planning.

3D modeling software such as Revit helps in accurate planning of ductwork design according to HVAC design principles. This ensures minimal pressure drops, air balance, and meets energy consumption benchmarks. 3D design tools also facilitate load calculations for heating and cooling requirements, airflow rate analysis, and duct sizing to optimize HVAC system performance.

Space constraints often challenge ductwork installation, limiting the available space for efficient airflow management. Proper airflow balancing and pressure control are essential to reduce noise pollution and energy loss. Additionally, precise insulation and duct sealing are critical to preventing air leaks and improving HVAC efficiency.

Accurate HVAC duct system design and installation are essential for greater HVAC system performance and sustainability. Incorrect sizing, inadequate insulation, and inconsistent duct sealing lead to a series of issues.

Imbalances in airflow lead to cold spots, hot spots, haphazard system operations, greater energy consumption, and stressed equipment. Duct leaks lead to poor air quality control, causing allergens and pollutants.

Proper ductwork design planning from the outset prevents costly HVAC retrofits, avoids structural disruptions, and mitigates risks of damage to walls, ceilings, and floors. Additionally, it ensures compliance with building codes, enhances occupant safety, and reduces risks associated with fire hazards and carbon monoxide leaks.

Accurate HVAC load calculations, appropriate duct material selection, and meticulous duct sealing and insulation are critical for long-term efficiency. Professional HVAC installation is key to optimizing performance and minimizing future issues.

Need professional HVAC design solutions? Discuss your project needs with our experts.

Contact us NOW »Optimizing HVAC ductwork design to achieve streamlined airflow requires an in-depth approach that balances practical limitations and thermodynamic principles.

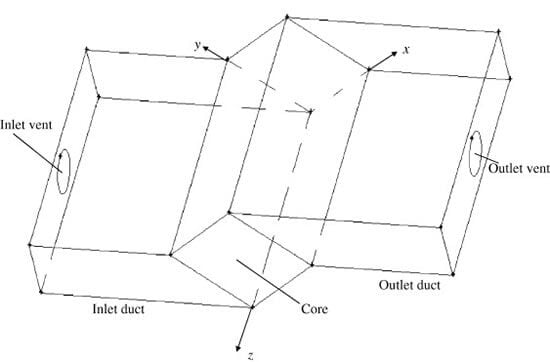

Advanced simulation techniques help predict pressure drops, identify turbulence zones, and maintain a smooth airflow pattern. Optimizing HVAC duct layout by minimizing abrupt changes, sharp bends, and excessive branching reduces frictional losses and enhances energy efficiency.

Incorporating gradual contractions and expansions with aerodynamic vanes mitigates flow separation and the formation of eddies in junctions and elbows. Furthermore, positioning dampers and balance valves delivers accurate control over airflow movement to ensure thermal comfort across multiple zones.

The material selection of air duct design plays an important role in creating streamlined surface finishes for fiberglass and galvanized steel that reduce roughness and enhance flow velocity.

Using duct connectors that are flexible with minimal ridges minimizes turbulent mixing and pressure changes. Perpetual maintenance, including inspection and cleaning for debris accumulation, fosters optimal HVAC system performance.

Flow distribution of the complete heat exchanger (Source: Science Direct)

Flow distribution of the complete heat exchanger (Source: Science Direct)

Success Story: MEPF Modeling for Hospitals in Ireland: Achieving Cost Savings

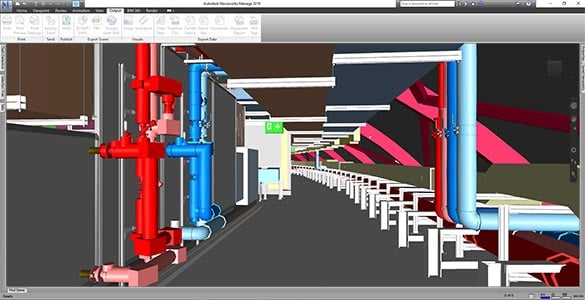

An engineering contracting company approached Hitech CADD services for a hospital project in Ireland. With 2D basic and markup drawings provided as input, a coordinated MEPF model with shop drawings was required. The team at Hitech CADD Services created clash-free MEPF models for mechanical, plumbing as well as fire protection systems. They also generated Shop, spool, module, schematic drawings and builders works drawings for fabrication and pre-manufacturing of MEP components.

The final deliverables helped the client with:

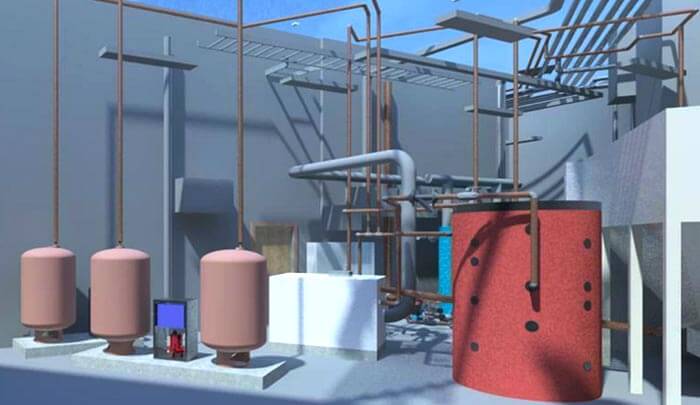

3D Revit MEP coordinated model for Plant room

3D Revit MEP coordinated model for Plant room

3D MEP model for Plant Room

3D MEP model for Plant Room

Transform your HVAC systems with our customized HVAC design services.

Connect with our team NOW »Maintaining air pressure balance in HVAC ductwork ensures proper airflow distribution and energy efficiency. Static pressure within the duct system must be regulated to prevent airflow imbalances, which can cause temperature inconsistencies and increased energy consumption.

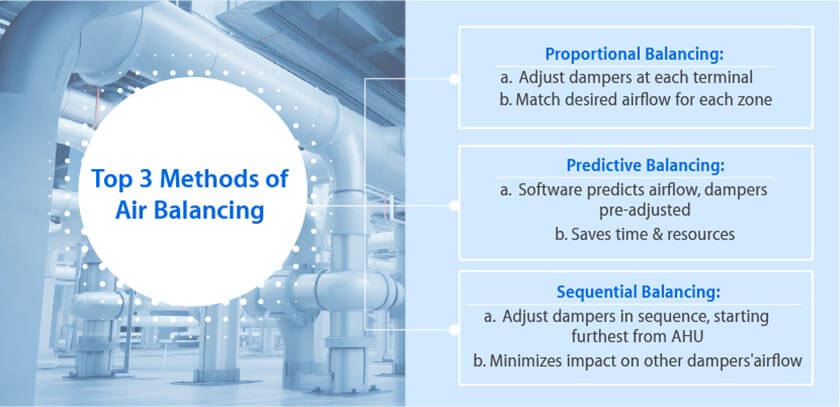

To achieve equilibrium, airflow measurements are taken at supply and return registers using flow hoods, anemometers, and other airflow testing equipment. These documented readings are compared against HVAC design specifications to identify discrepancies. Dampers are then adjusted to control air resistance, directing airflow to areas experiencing inadequate ventilation.

An iterative approach with multiple adjustments and recalibrations ensures optimal air pressure balance, improving indoor air quality and thermal comfort while enhancing HVAC system efficiency.

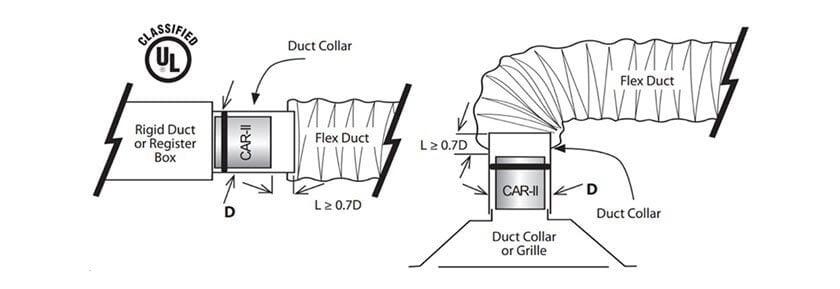

A constant airflow regulator is fitted into the neck of the supply duct to control air flow to deliver the design airflow regardless of pressure variations. (Source: American Aldes)

A constant airflow regulator is fitted into the neck of the supply duct to control air flow to deliver the design airflow regardless of pressure variations. (Source: American Aldes)

When enhancing HVAC ductwork systems for aerodynamic effectiveness, the selection of square air ducts versus round air ducts is critical. Round duct shape provides greater airflow characteristics based on minimal surface area, which results in lower friction and pressure loss. The continuous surface of round ducts reduces turbulence for effective air delivery and laminar flow.

Moreover, a square duct shape facilitates a greater surface area, which is in contact with the airflow that leads to higher friction and greater turbulence at edges and corners. However, square ducts provide greater space utilization to optimize floor spaces.

The choice of selection between square ducts vs. round ducts latches on specific project needs. In project scenarios that prioritize greater airflow and reduced noise generation, round ducts are the preferred choice. Whereas, in cases where space constraints are observed, square ducts offer a practical solution. Utilizing a hybrid setup such as round ducts for main runs and moving to square ducts for terminals strikes a balance between space optimization and higher efficiency.

Ductwork insulation is a significant component of energy-efficient and comfortable HVAC systems. Insulation provides a thermal barrier that reduces heat transfer between the conditioned air in the surrounding spaces and ducts.

During cooling operations, properly insulated HVAC ductwork minimizes heat gain from ambient air, ensuring that cooled air reaches its intended destination without efficiency losses. Similarly, in heating mode, insulation prevents heat loss, allowing warm air to be efficiently distributed to different building zones.

By reducing thermal loss, ductwork insulation enhances energy efficiency, leading to lower energy consumption and reduced HVAC operating costs. Moreover, it improves occupant comfort based on temperature consistency for the entire building, which eliminates cold or hot spots produced by temperature differences.

Beyond energy savings, insulated ductwork also helps in noise reduction, minimizing airflow noise and contributing to a quieter indoor environment. Ultimately, duct insulation plays a key role in enhancing HVAC efficiency, improving thermal comfort, and achieving significant energy savings in residential, commercial, and industrial buildings.

Source: House-Energy

Source: House-Energy

Get superior indoor air quality and energy efficiency with our professional HVAC design services.

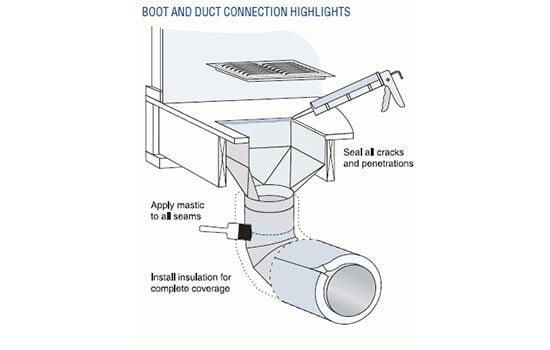

Contact us now to learn more »Leaks in HVAC duct systems compromise efficiency, leading to increased operational costs. These leaks occur at seams, joints, and weak sections, causing conditioned air losses before reaching designated spaces.

A systematic leak detection process involves using infrared cameras, smoke pencils, and pressure testing to identify problem areas. Sealing leaks with metallic tapes, aerosol-based sealants, and mastic sealants creates an airtight system, preventing energy wastage and improving air distribution balance.

Sealing leaks also mitigates dust, allergen infiltration, and pollutant accumulation, improving indoor air quality. Routine HVAC duct inspections ensure a leak-free system, optimizing HVAC performance, reducing energy consumption, and enhancing occupant comfort.

Success Story: Clash free 3D MEP Modeling for a European Plant Room Project

BIM consultants from Europe approached Hitech CADD services for a plant room project in Europe. Provided with 2D PDF files and manufacturing details of MEP equipment, the team at Hitech CADD services built Revit 3D MEP models, clash detection, and MEP shop drawings. The deliverables helped the client with:

3D MEP Modeling Revit

3D MEP Modeling Revit

MEP 3D Modeling for Plant Room

MEP 3D Modeling for Plant Room

Step 1: Perform Load (Manual J) Calculations

Step 2: Duct Sizing (Manual S ) Calculation

Step 3: Sketching Air Distribution System

Step 4: Material Selection & Insulation

Step 5: Sealing & Energy Optimization

Step 6: Secure and Seal Duct Connections

Ductwork is important for ensuring temperature consistency and air quality for the entire structure, which contributes to well-being and occupant comfort. Designing an effective and optimized HVAC ductwork system is complex. It requires consideration of various factors, including the building layout, occupancy patterns, air distribution patterns, and thermal load calculations.

Adopting the 5 HVAC design principles discussed above is critical to achieving required efficiency within HVAC ductwork equipment. Adopting a holistic design approach that includes airflow balance, duct placement, duct sealing, insulation, and duct materials selection supports contractors and engineers to build systems that produce superior performance, greater reliability, and energy savings.

Neglecting any of these principles compromises efficiency, elevates operating costs, and reduces occupant comfort. Therefore, investing in an efficient ductwork system is a fundamental step for the sustainability of the built environment.

You may also like

From 2D to 3D: Why Architects are Switching to BIM Modeling