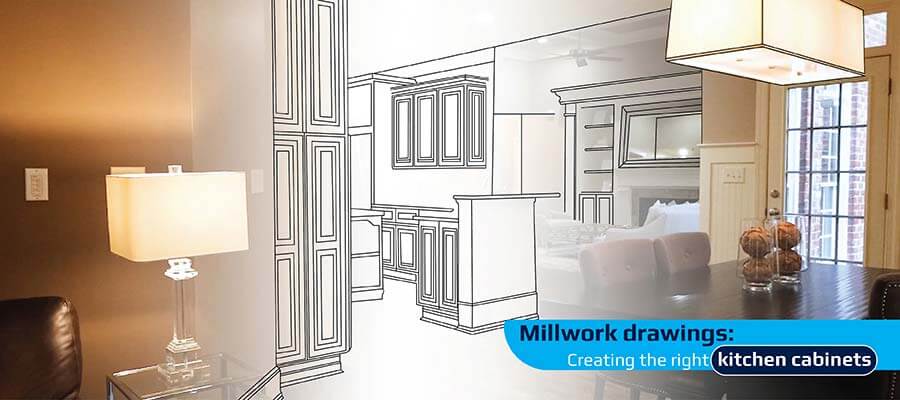

Architects and cabinet makers need to work in tandem to ensure the right designs, placement and positioning of kitchen cabinets. Millwork cabinet drawings bring both stakeholders on the same page by incorporating cabinet layouts and manufacturing information into a single file.

Table of Contents

Contemporary interior designs are fast gaining prominence in kitchens, playing a central role in conceptualizing spaces and defining function and aesthetics. Commercial kitchens have now transitioned from soot-laden cramped quarters to airy, well-lit and functional livable spaces.

Kitchen design is highly influenced by factors such as trends, space availability, project costs, and functionality. On any kitchen project, architects and cabinet manufacturers need to be on the same page to ensure flawless design development, manufacturing, and installation.

Millwork drawings for kitchen cabinets help to define the balance between durability and aesthetics while optimizing project costs. Detailed cabinet drawings enhance communication and ensure faster decision-making with complete information packed into a single file. Whether for new builds or kitchen renovation projects, millwork drawings ensure cabinet designs align with both aesthetic and functional requirements.

Kitchen cabinet design continues to develop with changing consumer preferences and technological advancements. Understanding current cabinet trends that influence millwork drafting plans helps architects and manufacturers make informed decisions.

The following key factors influence kitchen cabinet decisions:

Communicating these aspects accurately to the shop floor is the key to perfecting cabinet designs. Millwork drawings for cabinets preserve the design intent by encompassing detailed information and sharing it across stakeholders.

One ideally develops millwork drawings for custom kitchen cabinets from the architectural layouts of the kitchen. These drawings are detailed to get the right mix of sturdiness and looks.

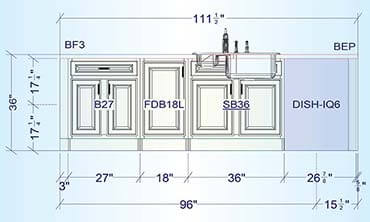

Let us look at the critical information needed in millwork drawings for kitchen cabinets:

As open and island kitchens become common, thorough planning for kitchen storage becomes crucial. Modern kitchens also make use of corner cabinets with circular and rotatable storage platforms to optimize space use. Space planning for micro apartments has become smarter with an entire line of new and multi-tasking furniture, including kitchen cabinets, becoming popular.

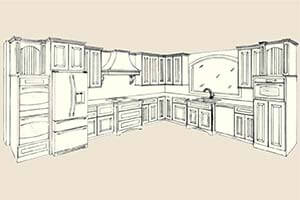

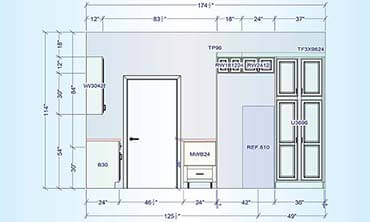

Architects need GA drawings readily available to put design aspects together. They break down the entire space into different modules, like cooking, utility, cleaning, etc. Once the zones are decided, the cabinet drawings are developed by allotting space for drawers, overhead cabinets, double-leaf cabinets, open shelves, pull-out cabinets, etc.

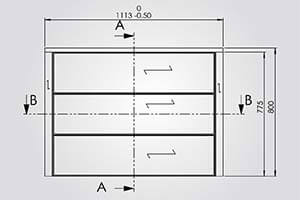

Once the space is allotted for different modules, and electrical appliances are assigned to their spaces, the furniture manufacturer needs to calculate dimensions for storage furniture. Some follow specific standards, while some are custom made to suit the sizes of electronic, electrical and other equipment. Millworks drawings account for local and global standards and specify dimensions that are viable.

The next stage is deciding the type of wood or metal as primary material and veneers. As the primary material of the cabinet changes, the total cost also varies. Wood may be cheaper than metal in some cases, but the latter is more durable and water-resistant. Further, in wood as a primary material, various categories dictate the price, such as MDF, particleboard, solid wood. Each of them has specific manufacturing instructions mentioned in the cabinet drawings for quality. The costs of metal parts also vary according to the specifications.

Streamlining Cost Calculation for Kitchen Cabinets

Cost calculation for kitchen cabinet can be tough. Hitech CADD Services’ millwork specialists leveraged Excel spreadsheet-based macros to eliminate tedious calculations. The result was an increased bid-to-win ratio.

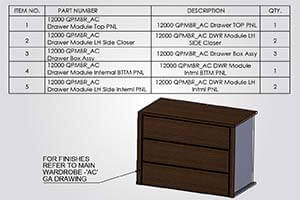

Cabinet shop drawings are the most critical documents for cabinet makers and millwork developers. A complete submittal for cabinet drawing includes manufacturing drawings with annotations, symbols, etc., and Bill of Material (BOM). DXF files are also used to leverage CNC machines and attain better finished cabinets.

These drawings detail every aspect of cabinet construction, including joineries, hardware placement, and assembly sequences. Some designers also create animated sequential videos to assist the installation site supervisor for tricky spaces, like under the kitchen counter or corner cabinets.

Stay Ahead with the Latest Kitchen Cabinet Trends in Millwork Drafting

Millwork drafters must continually refine their skills to keep pace with evolving kitchen cabinet styles, materials, and drafting technologies. Our white paper, “Top Kitchen Cabinet Trends Influencing Millwork Drafting Plans,” provides expert insights to help you stay competitive in the industry.

Several CAD tools help draft millwork drawings for kitchen cabinet designs, such as SolidWorks, AutoCAD, and specialized tools like 2020 Design.

Here is a comparison between the major cabinet design software:

SolidWorks/AutoCAD

2020 Design

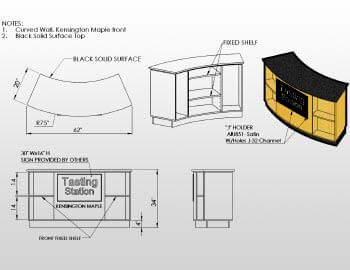

Streamlining Retail Furniture Design with SolidWorks and DriveWorks Automation

Hitech CADD Services’ engineers delivered detailed shop drawings for furniture used in retail food shops using to reduce error-count from 170/month to 18/month. By using SolidWorks as the primary tool for metal products, the team leveraged in-built DFM design methods. The team also developed catalogues for standard items and created models to minimize total engineering time.

Get accurate drafting services for your kitchen cabinet projects.

Contact to our Experts »Kitchens are becoming increasingly personalized with larger, more aesthetically pleasing cabinets. Customers demand unique designs for both residential and commercial spaces. While design preferences change, the need for accessibility and easy navigation remains constant. To meet market demands, architects and manufacturers must deliver design options faster without multiple approval cycles.

Visual configurators and automation in design development are becoming essential tools. Since cabinets are integral to kitchen spaces, their style must harmonize with other design elements. Millwork drawings facilitate both planning and manufacturing, helping designers realize their clients’ vision effectively.

Effective kitchen cabinet design requires precision, creativity, and collaboration. Millwork drawings serve as the bridge between concept and creation, enabling seamless communication between designers and manufacturers. As technology continues to develop, the integration of advanced CAD tools and automated processes will further streamline the design-to-installation pipeline.

Professionals who embrace these innovations while maintaining a focus on durability, functionality, and aesthetics will deliver superior results. For homeowners and commercial clients alike, investing in quality millwork drawings means investing in kitchens that are aesthetically pleasing and built to last through years of daily use.

You may also like

From 2D to 3D: Why Architects are Switching to BIM Modeling