BIM clash detection with 3D coordination techniques helps to resolve clashes early in a project’s life cycle. This improves interdisciplinary collaboration, removes delays, minimizes material waste, and reduces costly construction rework.

Detecting design clashes early isn’t just about avoiding rework and maintaining timelines; it’s a dance of precision that can save millions while maintaining project integrity. BIM clash detection and resolution is a strategic approach to mitigating project mishaps, ensuring seamless coordination and ultimately, maximizing safety and productivity.

BIM clash detection tools like Navisworks®, help to identify, inspect and report clashes from 3D models that have been integrated onto a common platform for a federated whole. And early clash identification and clash resolution, in the pre-construction phase helps to save costs, efforts and time.

Failure to resolve clashes, ranging from geometry-based issues to scheduling conflicts can lead to rework and material waste of about 7.25% to 35% of a project’s total cost, also causing project delays. And to prevent such losses we need to understand the three main types of construction design clashes – Hard, Soft, and Workflow or 4D – each with its unique characteristics and resolution strategies.

Clashes delay construction until stakeholders coordinate together to fix the issue. This inevitably affects project costs and schedules. Clashes occur due to:

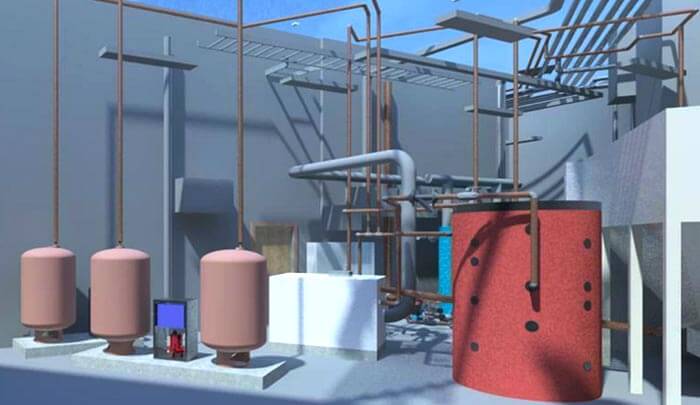

Illustrative case: Cost savings, complex project done within time

A client of HitechCADD services, a European BIM consultant, greatly benefited from our coordinated 3D MEP model with a clash-free plant room layout. It facilitated cost-saving measures, informed decision-making, and ensured timely and budget-compliant project completion.

Read Complete Case Study →

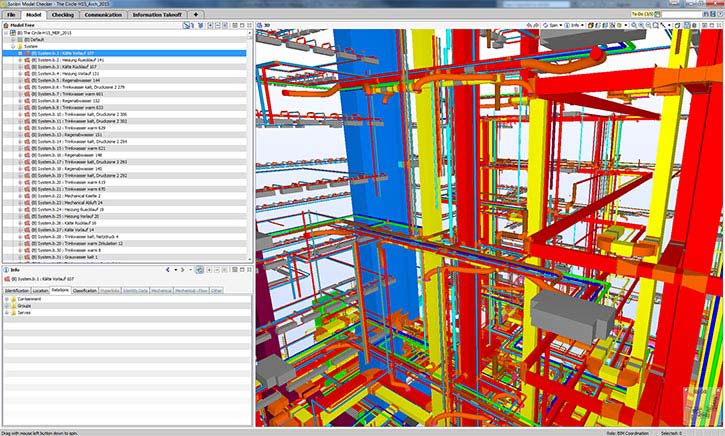

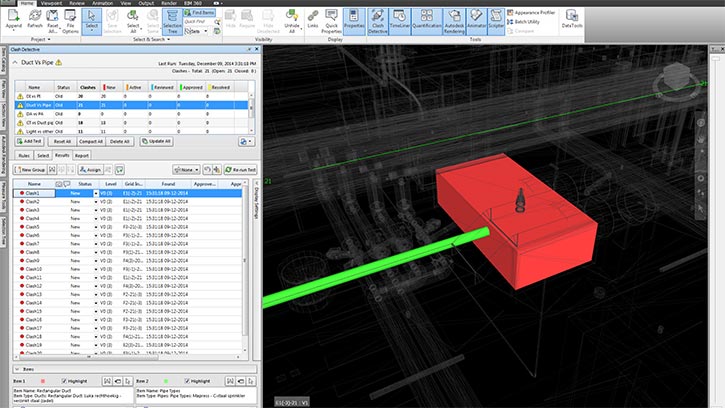

3D MEP model showing hard clashes between MEP components

3D MEP model showing hard clashes between MEP components

A Hard Clash occurs when two components such as a duct and a plumbing line or a pipe and a steel beam, occupy the same space. Hard clashes can be detected based on geometry or semantic and rule-based algorithms on the BIM objects with embedded information.

For geometry-based detection, tools like Navisworks® identify clashes like a beam running through a pipe, while rule-based clash detection on embedded object data eliminates common mistakes like pipes running through a wall or MEP fixtures against the ceiling.

Illustrative case: Clash-free MEP 3D model reduces costs, helps meet deadlines

A general contracting company in Muscat, faced challenges of rework on the new terminal building of an important international airport due to many clashes in the drawings that covered a large area of 350,000 m. HitechCADD services created a REVIT model and coordinated MEPF 3D BIM model, using Navisworks clash detection with proper QC channel. BIM clash resolution helped the company meet project deadlines while saving costs due to the clash-free and coordinated BIM model.

Read Complete Case Study →

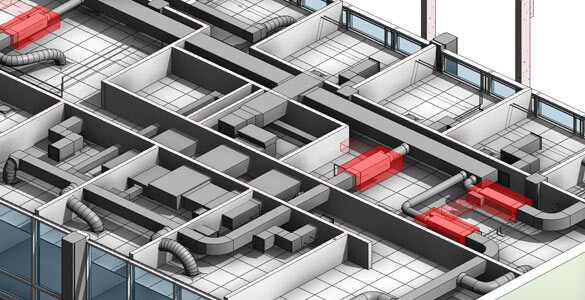

3D model showing soft clashes

3D model showing soft clashes

Soft clashes occur when an element’s spatial or geometric tolerance or buffer zone is breached. Spatial tolerance requirements are common in MEP services for facilitating maintenance at a later stage. For example, an air conditioning unit may require buffer space from a beam for safe and easy maintenance access.

Soft clashes if left unattended can cause maintenance problems and safety issues. For instance, if a live wire passes by a plumbing line, there is always a risk of issues with electric circuit completion or of short-circuit.

Providing sufficient object related tolerance data to software like Navisworks helps identify clashes as per applicable regulations and standards. This is especially relevant to high occupancy places like malls, airports and healthcare facilities to facilitate smoother operational maintenance.

Clash detection in BIM is extremely crucial and valuable. As per association of Construction and Development, it is estimated that, industry-wide, each identified clash saves about $17,000 on a project. On large projects, 2,000-3,000 clashes are usual. That is about $34,000,000 per project!

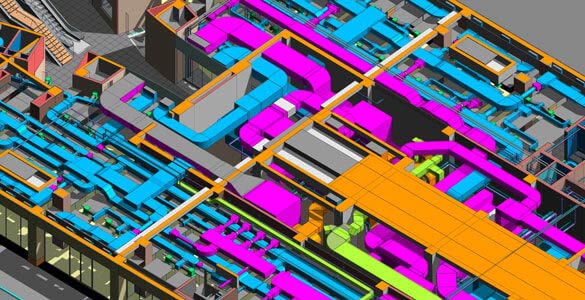

Workflow or 4D workflow clashes involve clashes related to contractor scheduling, equipment, and material delivery and general workflow timeline conflicts. Unlike hard and soft clashes, 4D clashes result from scheduling clashes of inter-disciplinary activities that eventually lower the efficiency of the entire construction project. Since each 4D clash has cascading effects on several disciplines and can bring work to a standstill, contractors cannot afford 4D clashes and have to opt for BIM clash resolution.

Developing a 4D construction sequencing timeline in Navisworks sets the start and end dates of each activity and helps the contractor schedule tasks effectively. A phased approach in 4D BIM eliminates the possibility of encountering any workflow clash and avoids site downtimes, thereby optimizing workforce productivity.

Clash detection software like Navisworks, facilitates 3D coordination between disciplines and generate clash reports by identifying and addressing areas of conflicts. Clashes identified prior to installation can be reviewed, approved and resolved before they move to the final construction stage.

Various disciplines like structural and MEP engineers use the architect’s model as a starting point to produce their own independent models. Clash detection in BIM is done to avoid clashes during design development phase.

While detecting and resolving clashes, it is important to ensure that all design disciplines (architecture, structural, and MEP) use the same coordinate system when creating their models.

Once the models are created, run clash detection tests using Navisworks clash detection. These tests entail superimposing the models from several disciplines and looking for spatial inconsistencies.

Once the conflicts are identified, the solution would include reworking the incompatible components, changing the size, or rerouting services, to gain a clash-free model.

4D sequencing provides a visual representation by connecting the construction schedule with the BIM model, thereby pre-emptively resolving any conflicts in construction sequencing.

Standardizing processes and integrating the models and data created by various disciplines into a master model or in common data environment such as BIM 360 improves collaboration.

Various disciplines like structural and MEP engineers use the architect’s model as a starting point to produce their own independent model, to avoid clashes during Design Development Phase.

BIM clash resolution with 3D coordinated models have the following benefits:

The main advantages of BIM-based clash identification and clash resolution include reduced rework, time savings, and improved project outcomes.

Using clash detection features in 3D modeling software ensures error-free, consistent and technically perfect designs. This leads to an effective and profitable construction process, which is of great value to all stakeholders including owners, engineers, architects and contractors.

You may also like

Top 5 Global MEP BIM Outsourcing Companies

Top 5 Architectural BIM Companies to Outsource

Top 5 Sheet Metal Design Companies to Outsource