Revit’s Building Information Modeling (BIM) tools are instrumental in addressing the complexities associated with plumbing system design, such as project coordination, process inefficiencies, integration challenges, and design intricacies like convoluted layouts and sloped piping. The implementation of Revit BIM results in a reduction of overall project costs while concurrently elevating the quality of the plumbing system.

The quality of plumbing system design serves as the foundation for the efficiency of Mechanical, Electrical, and Plumbing (MEP) systems in contemporary construction. A meticulously crafted plumbing design ensures the functionality, safety, and comfort of building occupants. Nevertheless, plumbing system design is inherently intricate.

Modern integrated MEP systems comprise a multitude of disparate components, including HVAC, electrical power distribution, lighting, and plumbing, which must function harmoniously. Design teams often encounter difficulties in swiftly identifying and rectifying MEP clashes without the aid of BIM tools. In such scenarios, Revit BIM emerges as the quintessential solution to surmount these challenges.

Table of Content

Accurate design of MEP systems plays a pivotal role in enhancing energy efficiency, lowering operational costs, and promoting sustainability in building construction, whether it is residential, commercial, or any other project. The sustainability aspect has become indispensable in modern construction.

Plumbing installations frequently grapple with inaccuracies and outdated designs. Flawed and obsolete blueprints lead to misplaced pipes, inefficient layouts, and incorrect water pressure. Efforts to resolve these problems often result in costly rework as unaddressed design errors lower plumbing system performance, cause leaks and water congestion.

Revit tools offer mechanisms for early identification of clashes in plumbing system designs, allowing for efficient pre-emption of these challenges before they impact MEP system installation and performance.

It is noteworthy that the global BIM software market size reached $9.6 billion in 2021 and is projected to grow to $23.954 billion by 2027.

Understanding the purpose and needs is key to designing effective and efficient plumbing systems. For instance, plumbing systems for hospitals must take into consideration patient rooms, operating theatres, labs, and other areas that require drainage and water supply to be assessed. It also requires plumbing design engineers to calculate the number of floors, fixtures, and other unique plumbing needs for every area of the hospital build.

Plumbing design engineers need to familiarize themselves with local and global plumbing codes supported by international standards and regulations applicable to multi-story and hospital projects. These codes guide design engineers with accurate pipe sizing, fixture needs, plumbing vent, drain, and waste system design.

Identifying the source of water, water pressure, average water demands, building occupancy, hydraulic calculations, flow systems, and redundant systems is critical.

Plumbing design engineers need to identify drainage points and design drainage piping backed by flow rates and plumbing codes. Ensuring accurate slopes prevents airlocks and implementing error-free ventilation systems through vent pipes, stack vents, and other venting assets prevents the formation of sewer gases.

An efficient plumbing layout drawing, or design must have separate drinking (potable) and non-potable water for flushing, water basins, etc. Potable water systems need safety measures to prevent backflow.

Plumbing design engineers need to add appropriate spacing to avoid soft clashes. Maintenance and repair runs should include locating shutoff valves, access panels, and cleanouts.

Coordinated plumbing system design in the preconstruction stage ensures error-free design reducing clashes during the installation of MEP systems.

Building plumbing system design engineers can utilize a myriad of BIM processes and Revit capabilities to achieve efficiency and overcome design challenges.

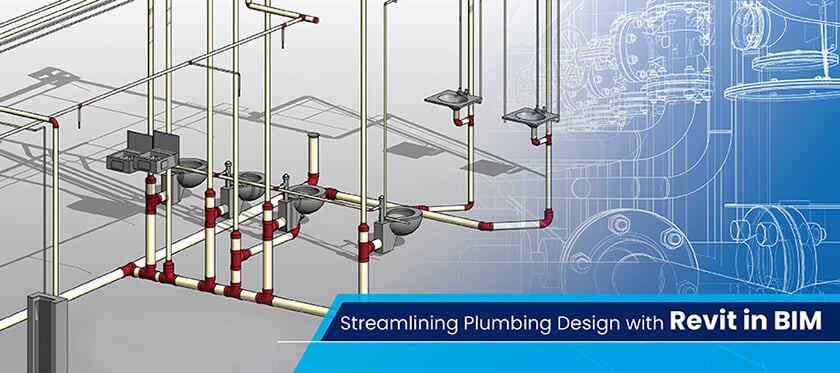

A coordinated 3D plumbing design BIM model enriched by Revit libraries improves model accuracy, and spatial geometry, and delivers life-like plumbing assets for precise schedules, cost estimates, and hassle-free installation.

Revit BIM can simplify MEP installation through interdisciplinary clash elimination and plumbing design services driven by BIM tools.

Coordination problems between various building systems lead to conflicts, inefficiencies, and operational issues, and require seamless communication and coordination for peak performance.

Clashes and conflicts between various MEP components are a result of inaccurate and obsolete MEP design, necessitating resolution through clash identification and resolution.

Inaccurate or incomplete design documentation leads to project risks, resulting in expensive rework, site safety issues, and project overruns. Ensuring precise and complete documentation is essential for optimal MEP performance.

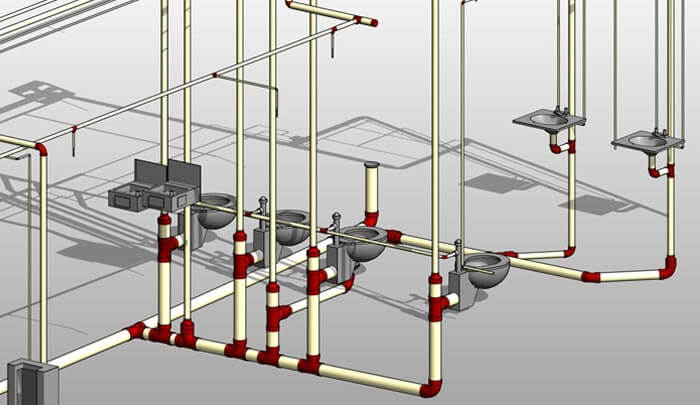

Capability 1: Clash detection: Revit’s BIM-powered plumbing system allows for clash detection between various building systems (mechanical, electrical, plumbing – MEP) before installation begins.

Impact: This helps identify potential conflicts early in the design process, reducing the chances of costly on-site clashes and rework. Revit uses a graphical system and provides document coordination to fix plumbing issues. Coordinated models and documentation with all specified details support clarity about deliverables and help manage the installation sequence. A coordinated set of plans reduces the need for RFIs during construction leading to time and cost savings.

Capability 2: Visualization: With Revit’s BIM capabilities, plumbing systems can be modeled in a 3D environment. This enables designers and installers to visualize the entire plumbing network.

Impact: Helps them understand the layout better and identify potential installation issues even before construction starts. If there is a pipe that runs below or above the floor, pipe elevations and view range can be determined.

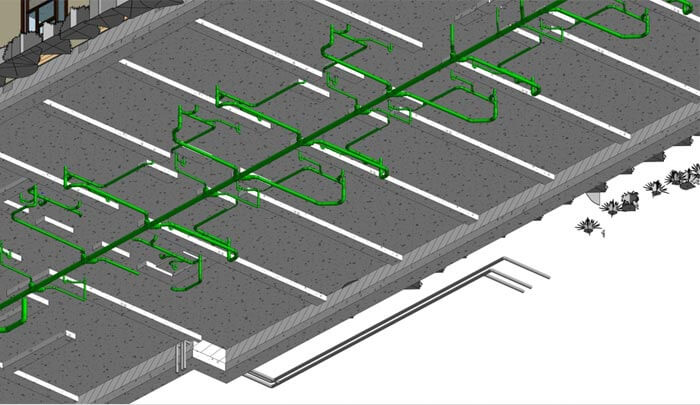

Capability 3: Improved coordination: BIM facilitates seamless collaboration among different disciplines involved in the construction process by integrating the plumbing system with other MEP systems within the same BIM model.

Impact: Clashes and inconsistencies can be resolved more effectively, ensuring a smoother installation process. Coordinating with other disciplines for sloping pipes as they require greater room. Plumbing designers can utilize Revit to view cable trays, ductwork, and other plumbing components. This also supports Architects calculate the final ceiling height for the complete building.

Capability 4: Material takeoffs and cost estimation: Revit’s BIM platform allows for automated material takeoffs and accurate cost estimation for plumbing installations.

Impact: This helps project teams to plan budgets efficiently and avoid cost overruns during the construction phase. Accurate material takeoffs of every plumbing component supported by their subsequent costs lead to accurate cost estimates.

Capability 5: Clash resolution and workflow optimization: The clash detection and resolution process within Revit’s BIM environment leads to optimized workflows and faster decision-making.

Impact: By resolving potential conflicts in the preconstruction stage, plumbing installation can proceed with greater certainty and efficiency, saving time and resources on-site. Utilizing Revit automation tools like Dynamo mitigates the need to perform repetitive tasks. Furthermore, the presence of automation negates human errors to improve design accuracy. Revit libraries included within the 3D modeling process enhances product realism, ensures accuracy, and correct material selection.

Plumbing systems coordinated with mechanical and electrical trades ensure clashes and spatial issues are identified and resolved in the preconstruction stage. With every clash eliminated and all the plumbing assets performing in unison with other systems, rework during actual installation is greatly reduced leading to faster project completion.

Visualization is one of the key capabilities of BIM backed by Revit as a strong model authoring tool. Compatible file formats make it easier for every stakeholder to access design files and collaborate on a single platform. 360-degree visualization of every plumbing asset within the 3D model improves visibility, faster modifications, and quick approvals.

BIM improves coordination amongst stakeholders for efficient plumbing design. Accessing a shared platform, architects, engineers, plumbers, and contractors can access and update the project information in real time. This level of information transparency lowers errors, doubts, and delays, leading to more effective workflows and cost savings.

BIM-based 3D plumbing layouts provide specialty contractors with accurate and complete drawings for reduced rework. Spool and shop drawings extracted from coordinated and clash-free 3D models provide greater accuracy and clarity for fabricators to manufacture dimensionally accurate plumbing components.

Designers’ Manufacturing Struggles: A Roadblock for 40%

3D BIM models enriched by 4D scheduling provide a complete snapshot of the project timeline through immersive simulations. 4D scheduling improves site logistics leading to faster project completion. The reinforcement of accurate quantity takeoffs and BOMs reduces material waste, while 5D cost estimation provides accurate cost estimates for every plumbing asset or component.

Integrated plumbing product libraries in Revit offer various MEP components to ensure accurate and efficient design and installation. Through detailed data and accurate 3D models, architects and designers can seamlessly incorporate plumbing components to guarantee hassle-free installations and required system performance to ensure required project outcomes.

BIM-driven coordinated plumbing MEP drawings and detailing streamlines the installation of MEP systems through collaborative approach. By integrating 3D models and information, clashes and conflicts are resolved in the preconstruction stage to ensure accurate plumbing layouts and effective workflows. This drives seamless communication between multiple teams and reduces rework, leading to better MEP installation

Optimize plumbing in BIM using Revit today.

Call us NOW »A design drafting company from Sydney, Australia approached our team for a commercial healthcare project. The business needs were specific including a plumbing layout supported by hydronic equipment. With 2D plumbing drawings as input, the team was to create a 3D coordinated BIM model at LOD 300. During the plumbing LOD 300 modeling process, the team had to perform modeling coordinate architecture and structure for clearances and resolve clashes.

Generating the final 3D BIM model and running it through multiple QC channels supported the client with clarity in plumbing fixture details and insulation details. With a coordinated and clash-free model in place, detailed visualization of drainage systems (underground and upper floors) could be achieved to make informed decisions

Detailed MEP 3D Model

Detailed MEP 3D Model

Revit MEP 3D Modeling

Revit MEP 3D Modeling

Outline the specific objectives and scope of the plumbing system design to ensure that all the disciplines are on the same page and operating towards shared goals.

Create consistent and efficient processes for 3D modeling, design documentation, and information management to ensure performance and lower errors during plumbing fabrication and installation.

Build a customized template in Revit using predefined parameters and views curated to plumbing system design needs and streamlining the 3D modeling process.

Utilizing high-quality and industry-specific Revit families for plumbing components ensures accuracy and consistency within 3D models and design documentation.

Collaborating with other disciplines, including architecture, structural engineering, mechanical and electrical engineering ensures clash avoidance through coordinated building design.

Perpetual updates and 3D model validations for design modifications ensure every project stakeholder has complete access to accurate and updated documentation

Deploy best practices to optimize the 3D Revit model performance through required level of detail, view filters, and optimized parameter settings.

Engaging with every stakeholder, including clients, contractors, and consultants, early in the design stage, helps address issues, and ensures final plumbing design meets project and client needs.

3D plumbing design with BIM and Revit powered by AI and Machine learning tools will continue to optimize parametric modeling capabilities allowing plumbing design engineers to explore unlimited opportunities. Present-day AR technology has showcased unprecedented capabilities to overlay 3D models over plumbing layout drawings for immersive visualization, analysis, and simulations.

Pulling data from various sources including specifications, codes, estimates, scheduling, and other geometric data would become easier for plumbing design engineers with the power of AI algorithms. Artificial Intelligence (AI) would drive the next step in plumbing design with design optimization through quick improvement suggestions or prototypes for pipe sizes, layout options, water consumption, and other critical parameters.

AI automation would churn out multiple plumbing design probabilities to save effort and time. This would also lead to an increase in performance rating for plumbing assets connected with other Mechanical and electrical systems. AI-powered clash detection and resolution would cut out conflicts completely for the smooth integration of other systems into the overall building design.

A vast amount of data could be processed by AI tools to identify design trends and anomalies. These data patterns can be analyzed by plumbing design engineers to create models for water conservation, efficiency improvements, and other opportunities.

AI-driven documentation including drawings, specifications, and reports would reduce inconsistencies leading to greater data accuracy and faster field installation. BIM processes and tools like Revit in the future would be able to integrate seamlessly with these AI tools to enhance the entire plumbing design process.

In Conclusion, Revit BIM, combined with AI advancements, heralds a new era in plumbing system design and installation. The integration of BIM and AI technologies streamlines the design process, minimizes errors, and enhances collaboration among stakeholders, ultimately revolutionizing the way plumbing components and systems are designed and constructed.

Plumbing shop drawings are important for precision in construction. They detail the layout, dimensions, and specifications of plumbing systems, ensuring accurate installations. These drawings serve as a crucial guide for plumbers, reducing errors, enhancing efficiency, and ensuring seamless integration within the overall construction process.

A plumbing drawing is a detailed illustration of a building’s plumbing system. It outlines pipe layouts, fixture placements, and technical details. Plumbing drawings are crucial for construction planning as they ensure accurate installations, minimize errors, and facilitate efficient communication among various stakeholders throughout the construction process.

A plumbing system includes various components such as supply pipes that bring in water, fixtures like sinks and toilets, drains to remove wastewater, and vent pipes for proper air circulation. These elements are vital to ensure a functional and efficient plumbing system within residential, commercial, or industrial structures.

Designing a building’s plumbing system involves careful planning. Consider the structure’s layout, water supply needs, and fixture placements. Calculate pipe sizes, incorporate water-saving fixtures, and ensure compliance with local codes. Collaborate with architects and engineers for an integrated design that optimizes efficiency, durability, and water conservation.

Revit software revolutionizes plumbing design by offering a 3D modeling platform. It enables precise placement of pipes, fixtures, and fittings, enhancing visualization and coordination. With real-time updates, seamless collaboration, and data-rich models, Revit streamlines the entire plumbing design process, ensuring accuracy and efficiency in construction projects.

Our preferred plumbing layout software is Autodesk Revit. Renowned for its 3D modeling capabilities, Revit ensures accurate placement of pipes, fixtures, and fittings. With real-time collaboration features, it enhances efficiency and precision in plumbing design, making it a valuable tool for our projects.

You may also like

Top 5 Global MEP BIM Outsourcing Companies

Top 5 Architectural BIM Companies to Outsource

Top 5 Sheet Metal Design Companies to Outsource