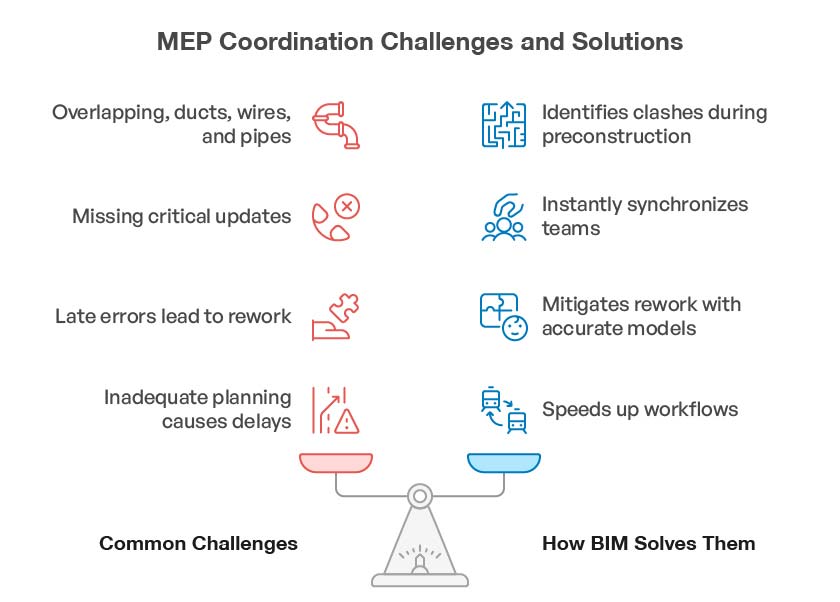

Lack of BIM-based MEP coordination often causes clashes, delays, and costly rework due to out-dated 2D drawings and disconnected workflows. BIM enables real-time multi trade collaboration, early clash detection, and optimized sequencing for construction projects.

MEP coordination failures are a hidden drain on budgets and schedules. When trades work in isolation, design conflicts such as HVAC ducts obstructing structural elements or electrical conduits clashing with plumbing go unnoticed until installation, leading to costly rework and project delays.

Traditional 2D workflows make it difficult to detect these issues early. BIM-based MEP coordination solves this problem by creating a centralized, clash free model that enables real time collaboration, optimizes spatial planning, and streamlines execution. With real time clash detection, automated conflict resolution and digital workflows, teams can resolve conflicts before construction begins, not after.

This article explores BIM-based MEP coordination, its methodologies and how it enhances multi-trade collaboration, efficiency and cost control.

Table of Contents

Construction projects require precise integration of various systems structural components, HVAC, plumbing, and electrical wiring. When these systems are designed separately, conflicts arise, leading to delays, rework, and increased costs.

Effective MEP BIM coordination goes beyond preventing design conflicts; it establishes a structured workflow that enhances collaboration between trades. When mechanical, electrical, and plumbing teams work in silos, even a minor change like an HVAC duct shift can disrupt the entire layout, affecting plumbing and electrical routing. Without a proactive approach, these misalignments lead to repeated redesigns and project delays.

With BIM-Based MEP coordination, all trades work within a centralized Revit 3D model, ensuring design alignment before installation begins. Automated MEP clash detection identifies spatial conflicts early, enabling teams to resolve them digitally rather than on-site.

This approach does not just reduce issues it streamlines the entire construction process, improving efficiency and project outcomes.

Historically, MEP coordination relied on 2D drawings, fragmented communication, and reactive problem solving. This outdated approach creates:

Optimize collaboration and eliminate clashes with MEP coordination services.

Connect with our experts NOW »BIM shifts coordination from a reactive process to a proactive strategy. Instead of identifying problems during construction, BIM-based MEP collaboration ensures that systems are integrated correctly from the outset.

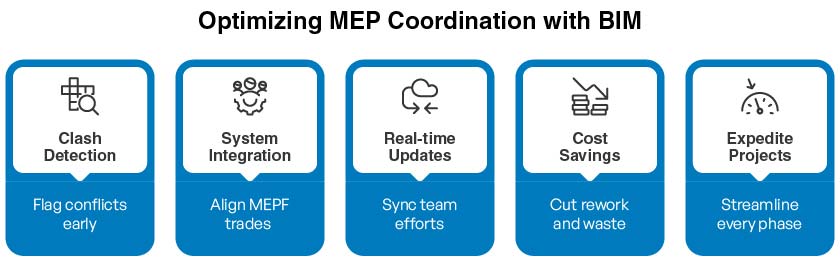

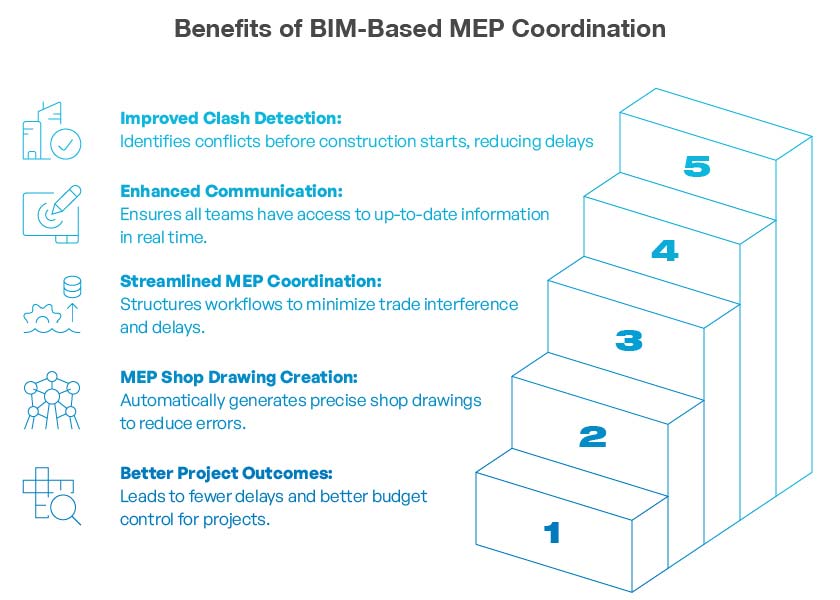

Key advantages of MEP coordination include:

Unexpected clashes between mechanical, electrical and plumbing (MEP) systems are a leading cause of delays and rework in construction. Issues like ducts interfering with structural beams or electrical conduits blocking plumbing routes can bring work to a standstill, forcing teams to find last-minute solutions onsite.

BIM coordination tools like Navisworks and Revit identify these conflicts before construction begins, reducing disruptions and avoiding expensive rework.

Key advantages of BIM-driven clash detection:

Miscommunication in construction can be just as damaging as design errors. If one trade works from outdated plans, costly mistakes and rework follow. BIM eliminates this risk by ensuring that all stakeholders have real-time access to the latest information.

Coordinating MEP installations requires careful scheduling to prevent workflow disruptions. If trades work out of sequence, inefficiencies arise, leading to delays and unnecessary rework. BIM provides a structured process that ensures smooth collaboration between trades.

By structuring workflows efficiently, BIM minimizes delays and ensures every trade is on-site at the right time.

Getting MEP installations right the first time starts with accurate shop drawings. When drawings are unclear or incorrect, things go wrong fast – misaligned ductwork, wasted materials, and rework that eat into time and budget.

Revit BIM automation takes the guesswork out of the process, generating MEP shop drawings that are clear, precise and ready for execution.

Here’s how it helps:

The result? Faster approvals, fewer mistakes, and a workflow that moves forward without costly setbacks.

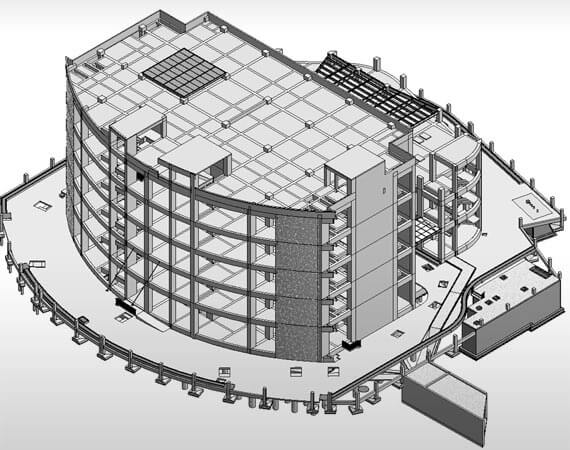

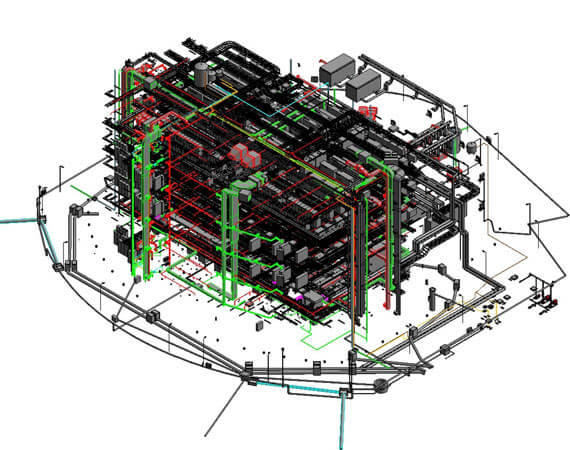

Multi-trade BIM coordination for a data center building, India

3D Architectural BIM Modeling

3D Architectural BIM Modeling

3D Structural BIM Model

3D Structural BIM Model

3D MEP BIM Modeling

3D MEP BIM Modeling

A leading architectural firm needed a coordinated and clash-free multi-trade 3D model with sheet setup, schedule and joint details for a data center building in India.

The team of BIM experts at Hitech CADD Services used the 2D drawings provided as input and created a 3D Revit model. They identified and resolved inter-disciplinary clashes (for architectural, structural and MEP disciplines) using Navisworks. The final deliverable was a clash-free and coordinated model that led to:

At the core of BIM-based MEP coordination is efficiency, cost control, and predictability. With fewer clashes, improved communication and structured workflows, projects stay on track.

With BIM-based MEP coordination, contractors experience fewer delays, better budget control, and a more predictable construction process.

And the benefits don’t stop there – early cost analysis within BIM allows stakeholders to make informed budget decisions before construction even begins. No more unexpected costs or last-minute surprises.

When teams work smarter, projects run smoother.

Build smarter, faster, and safer with MEP clash detection services.

Reach out to our MEP experts today »

Coordinating multiple systems MEPF (Mechanical, Electrical, Plumbing and Fire) requires precision, as each trade has unique spatial and functional requirements. When these systems are not properly integrated, conflicts arise, leading to rework, inefficiencies, and budget overruns. BIM provides a structured, data-driven approach to aligning MEPF trades, detecting clashes early, and optimizing installation workflows for seamless execution.

Each MEP system operates under distinct spatial, regulatory, and functional constraints, making trade prioritization essential. Without proper coordination, one system may obstruct another, leading to inefficiencies and compliance risks.

Key challenges in MEP prioritization

As construction projects grow in complexity, BIM models for MEP coordination become data-heavy, affecting performance and collaboration speed. Without proper model management, clash detection becomes slow, coordination efforts stall, and system inefficiencies increase.

A lack of standardization in BIM coordination leads to inconsistent modeling, misalignment between trades, and delays in conflict resolution. Establishing clear BIM Execution Plans (BEPs) and Level of Development (LOD) standards ensures that all MEP disciplines follow a consistent, structured workflow throughout the project lifecycle.

Boost design accuracy and reduce costly rework with BIM-based collaboration.

Connect our team of Revit BIM experts »

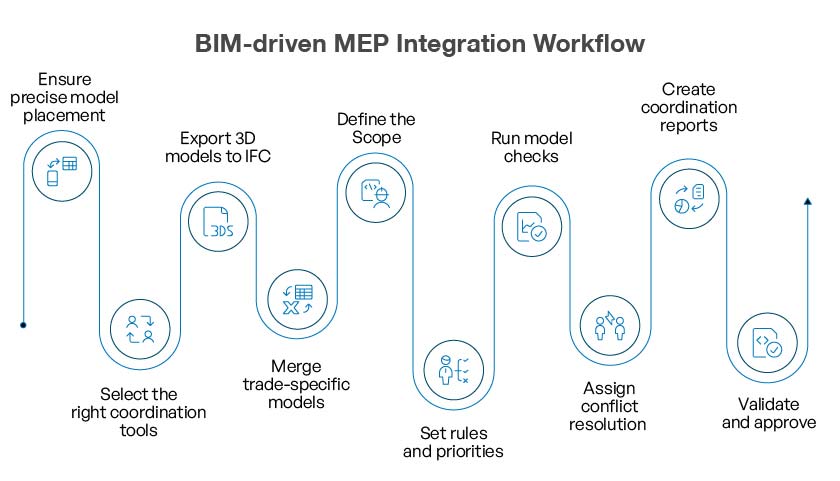

Efficient MEPF (Mechanical, Electrical, Plumbing, and Fire Protection) coordination in BIM requires a structured workflow that integrates multiple disciplines while minimizing conflicts. The BIM MEP coordination process follows a systematic approach to ensure seamless model integration, clash detection, and issue resolution before construction begins.

Ensuring accurate model placementAlign all MEP models with the architectural and structural framework using a shared coordinate system to prevent spatial conflicts.

Selecting the right BIM coordination tools Use Navisworks, Revit, or BIM 360 to manage clash detection, coordination, and model integration across disciplines.

Exporting models to IFC for cross-platform compatibility Convert models to IFC format to enable smooth collaboration between different software and stakeholders.

Merging discipline-specific models into a federated modelIntegrate separate MEP models into a centralized federated model to visualize potential conflicts before construction.

Defining the scope of coordinationIdentify critical zones, clearance requirements, and compliance factors to ensure efficient clash detection.

Setting clash detection rules and prioritiesEstablish clash tolerances and priority levels to focus on resolving critical interferences while filtering minor ones.

Running model checks and conducting clash analysisUse automated clash detection tools to identify and categorize conflicts between different trades.

Assigning conflict resolution tasks to teamsAllocate responsibility for resolving clashes to the appropriate trade before moving to fabrication.

Generating and distributing coordination reportsDocument clash detection results, resolution status, and model updates to keep teams aligned.

Performing Final Validation and ApprovalRun a final clash check to confirm all issues are resolved before construction begins.

Following best practices ensure that BIM delivers consistent, high-quality coordination across all phases of the project.

Streamline your MEP workflows with customized BIM solutions.

Partner with us now »

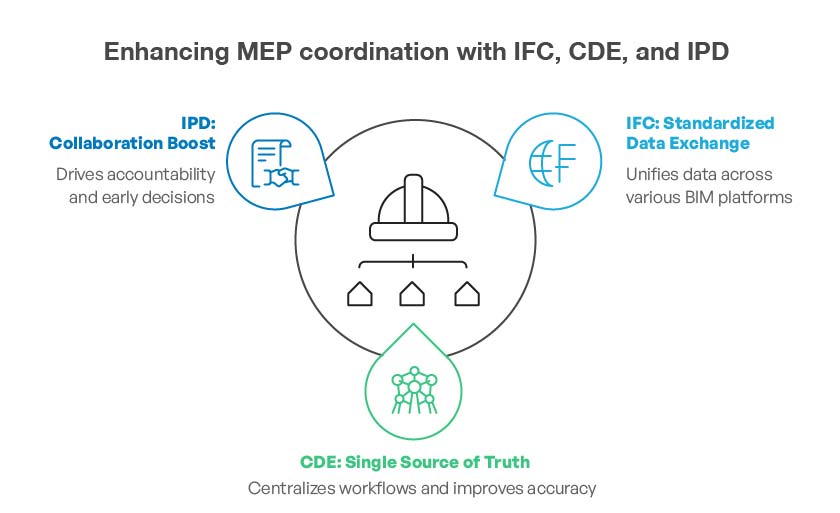

Traditional construction workflows often create fragmented coordination, design conflicts, and reactive problem solving. A different approach one that focuses on collaboration, shared accountability, and early-stage decision-making to improve project efficiency and reduce risks.

BIM relies on Industry Foundation Classes (IFC) to ensure interoperability between different software platforms, enabling seamless model sharing without data loss. IFC maintains geometry, object metadata, and trade-specific details, preventing workflow fragmentation and inconsistencies across disciplines. By using IFC, MEP teams can exchange and coordinate models accurately from design to fabrication, regardless of the BIM tool used.

A Common Data Environment (CDE) centralizes BIM data, model versions, and coordination reports, ensuring that all MEP trades work with the latest validated information. By integrating automated approvals, real-time updates, and structured issue tracking, CDE eliminates miscommunication and coordination delays. AI-driven analytics further enhance risk management, allowing teams to predict and resolve conflicts before construction begins.

BIM’s impact extends beyond project-wide decision-making it fundamentally improves how different trades coordinate and execute their work.

While IPD provides the framework for early collaboration and shared accountability, BIM is the tool that makes this approach work in practice.

BIM enhances Integrated Project Delivery (IPD) by fostering real-time collaboration and shared accountability among MEP trades. Instead of resolving conflicts reactively, BIM allows contractors, engineers, and fabricators to work within a shared model, ensuring early clash detection and optimized constructability reviews. Parametric modeling enables instant design adjustments, minimizing delays, cost overruns, and misaligned trades.

Unlike standard multi-trade collaboration, where different teams coordinate as needed, BIM in an IPD workflow ensures that trade coordination is proactive, structured, and fully integrated into the project’s overall success plan.

BIM has already transformed how MEP systems are designed and coordinated, but new advancements in technology are pushing this even further. Digital twins and Virtual Design and Construction (VDC) are setting new standards for real-time monitoring, predictive analytics, and precise execution.

A digital twin is more than just a 3D model it’s a live, data-driven representation of a building that evolves with real-time sensor data. This means teams can not only design with accuracy, but also track system performance long after construction is complete, enabling efficient MEP coordination across various building systems.

By connecting IoT sensors to BIM models, digital twins for MEP systems help project teams identify risks, fine-tune performance, and improve long-term building maintenance – ensuring that designs aren’t just accurate on paper but function optimally in the real world.

VDC takes BIM coordination a step further by allowing teams to test MEP installations in a virtual environment before work begins.

With VDC and AI-driven modeling, teams gain greater accuracy, reduced errors, and a data-backed approach to decision making before a single component is installed.

BIM-based MEP coordination is no longer optional, it’s essential for reducing conflicts, optimizing trade workflows, and ensuring on-time, on-budget project delivery.

But implementing BIM successfully takes more than just software. It requires expertise, collaboration and a proactive approach to coordination. That’s where the right BIM partner makes all the difference.

With expert BIM coordination, you can:

You may also like

BIM-Based MEP Coordination for Multi-Trade Collaboration