Project Team Leader

Hazard Protection Technologies Company, UK

Business Needs

Challenges

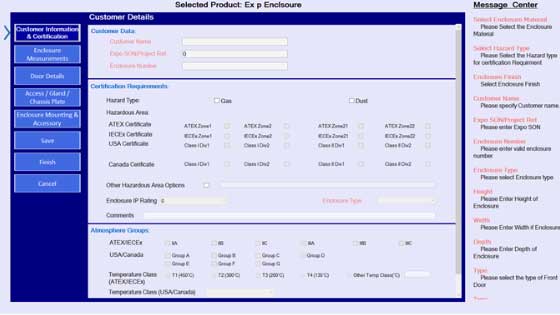

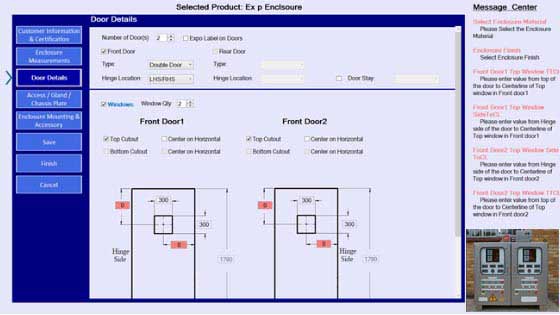

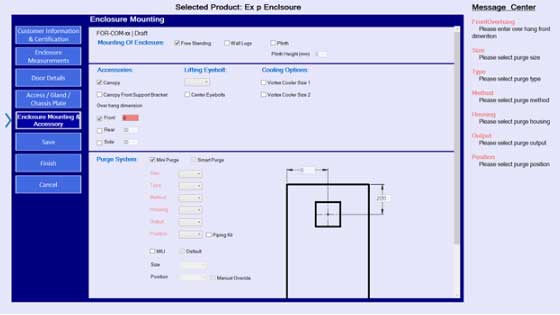

Developed DriveWorks product configurator for multiple design combinations of electrical enclosures.

The safety equipment manufacturer was directed to Hitech by DriveWorks UK team while looking for a competent DriveWorks partner. The primary need for partnership was to accomplish configurator development for automating electrical junction box design originally initiated by another reseller who couldn’t clear off the roadblocks.

Hitech automation experts carried out an in-depth study of the sales sheet and current overall implementation of the project to make improvements in configurator developed by previously hired DriveWorks reseller.

Safety equipment manufacturer was able to setup configurator for his sales team without any snags in the models, drawings, 3D previews or any output for any given selection made by the user.