Business Needs

Challenges

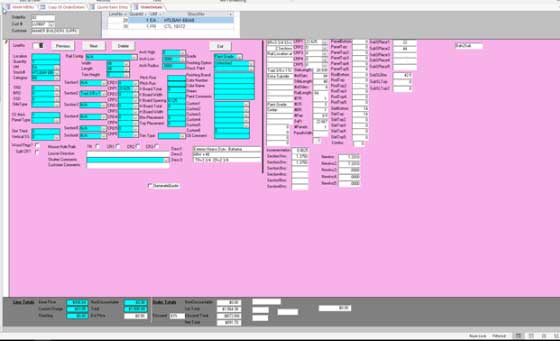

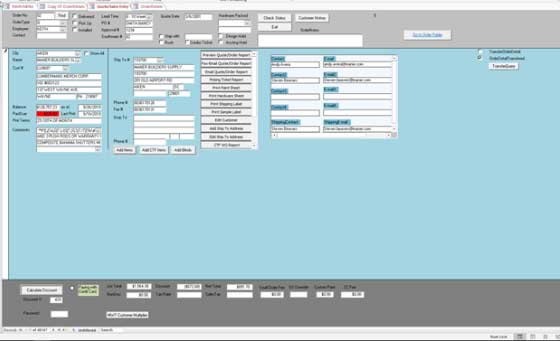

Created rules and scripts to automatically fetch the data from MS Access database to DriveWorks configurator for custom windows and louver designs.

When the US based manufacturer of millwork contacted us, their design team had already achieved major milestones in creating DriveWorks configurator. However, given the higher number of design variations for louvers, getting through the final outcome by automating the entire process the manufacturer needed a DriveWorks expert on board.

Expertise of Hitech’s DriveWorks team’ allowed recreating the master models in a way that the client now could create a multiple product variant with one master model and drawings for which they used a separate model for different products. The team developed automation at three levels namely for CAD drawing, quoting and auto email setup.