Business Needs

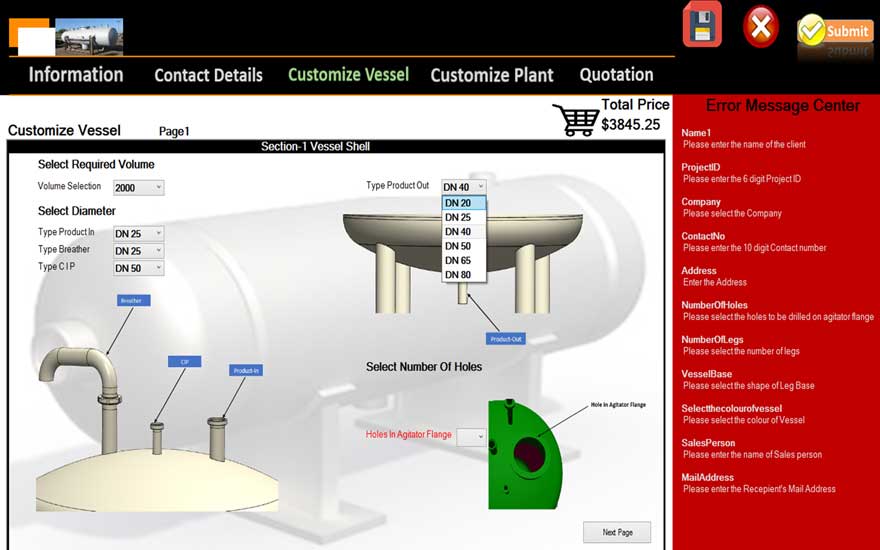

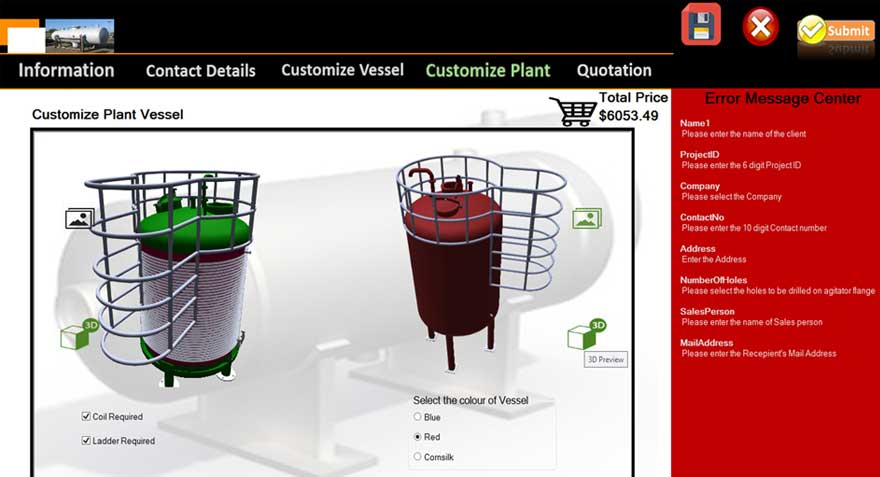

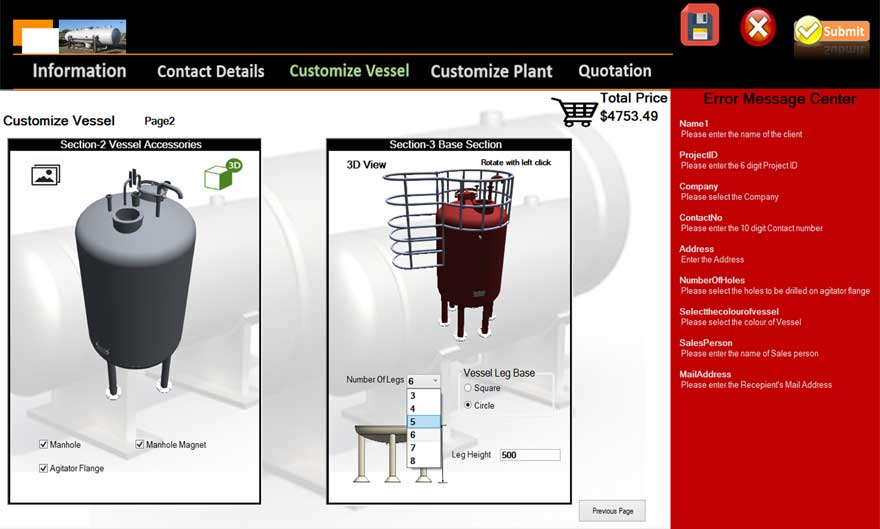

The client wanted to develop a Tank Configurator, remove the current time consuming manual practice of designing the model as well as decrease quotation time. They needed to develop an interactive Configurator, which was user friendly as well as having all the possible options available according to their needs.

Challenges

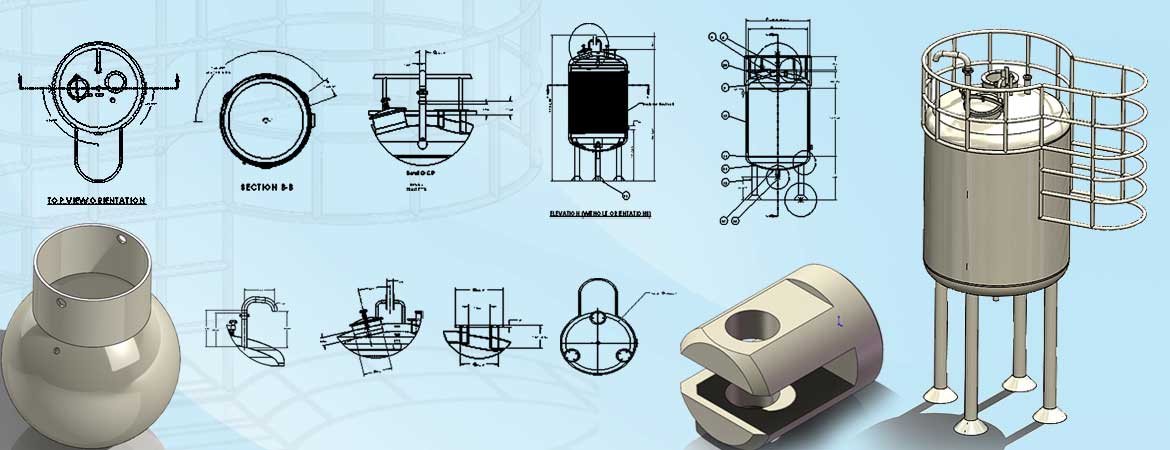

Created pressure tank configurator using DriveWorks for accurate quoting and automate design of manufacturing drawings.

Design Automation engineers at Hitech understood the need to fasten the process of custom model creation of the pressure vessel and its accessories. After analyzing the need based designing of custom tanks, Hitech Design Automation Experts suggested to develop base frame models in SolidWorks and implement DriveWorks and automate the custom tank modeling and reduce time.

Automating the entire process helped the client save time in accurate quoting and designing of manufacturing drawings. The client found an opportunity to offer more customization to his customers and improve on the quality and quantity of final deliverables due to reduced error ratio.