Business Needs

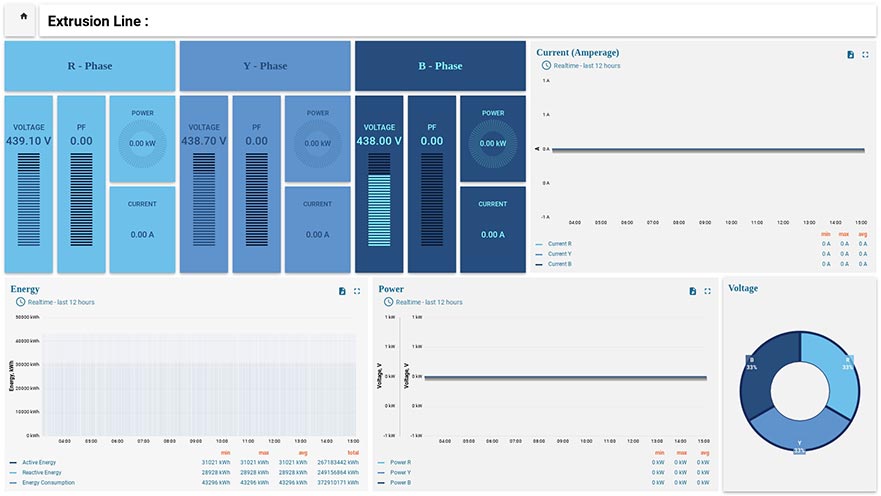

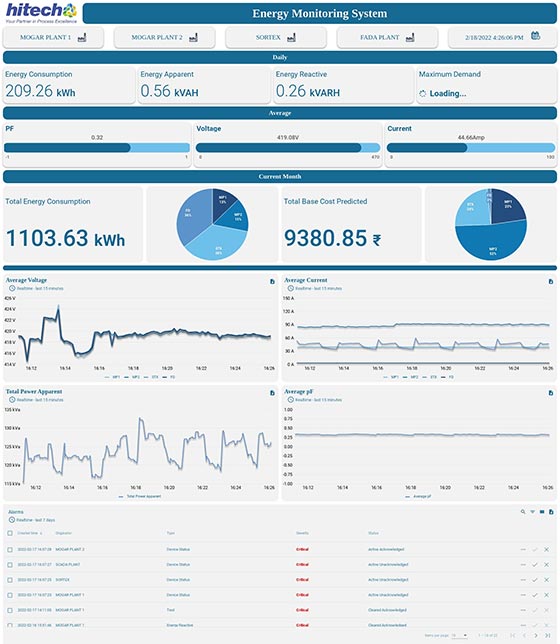

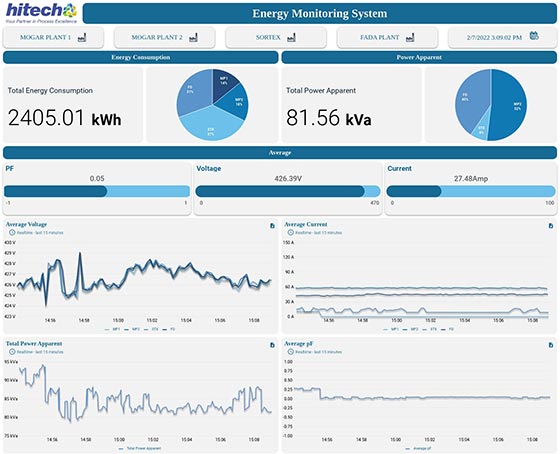

The steel bars manufacturing plant housed heavy duty shot blasting machine and six extrusion lines. They were permitted to use 95KW power per month; overshooting it could result in severe penalties. Using manual methods to track power consumption resulted in shutting down heavy machines that affected production capacity.

The manufacturer was looking to:

Challenges

Deployed smart sensors, energy meters and gateway devices to remotely monitor power consumption. Consolidated data in interactive dashboards for real-time alerts.