The client shared 3D Revit models of the football stadium as input files and initially, five engineers were dedicated to the project. This small project team acquired drawing requirements and manufacturing capabilities to create drawings as per need.

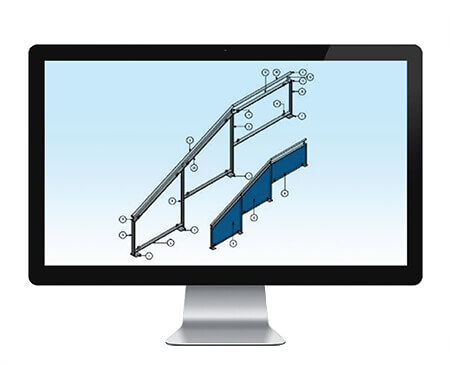

3D Revit Models of Football Stadium

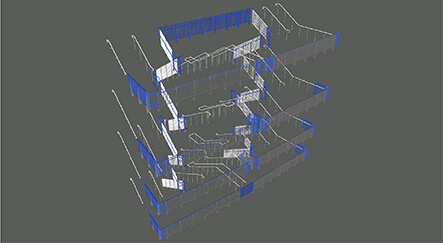

3D Revit Models of Football Stadium

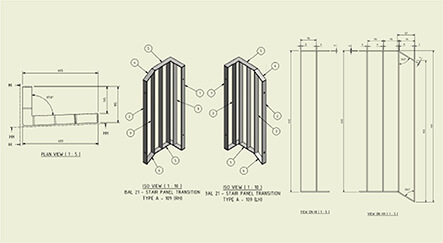

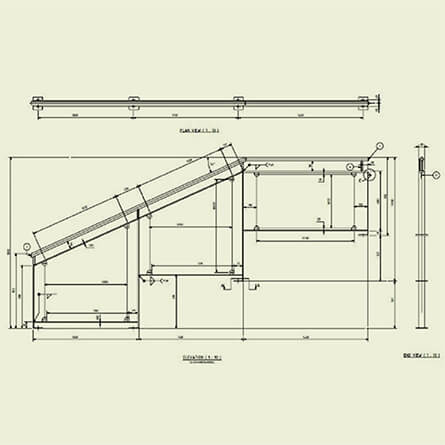

Manufacturing Drawings for Balustrades

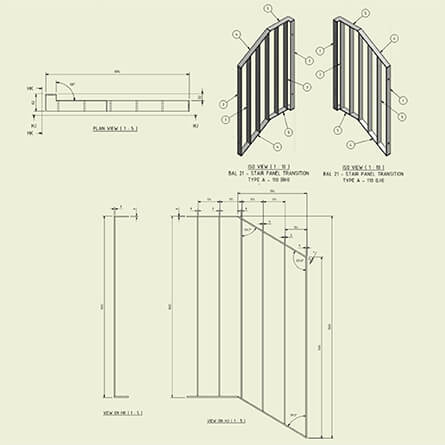

Manufacturing Drawings for Balustrades

- A thorough study of models in Revit architectural design software was carried out and relevant details for balustrades and handrails were converted in Inventor

- CAD engineers set initial 2D drafting and 3D modeling standards to be followed across the project

- The project cycle was such that three processes of designing in Revit, CAD drafting in Inventor, and manufacturing processes were running simultaneously. Hence, the Inventor team needed to develop drawings and submit them on daily basis to keep the cycle running.

- During modeling conversion, the team identified common parts that were used repetitively and developed a CAD library to save time during modeling later

- Continuous feedback from the client helped the drafting team to include customer demands during the early drafting stages

- Final 3D models and 2D manufacturing drawings were handed over to the client for minimum manufacturing waste

- As the work influx increased, the project team grew by four times wherein existing team members provided training to the new ones