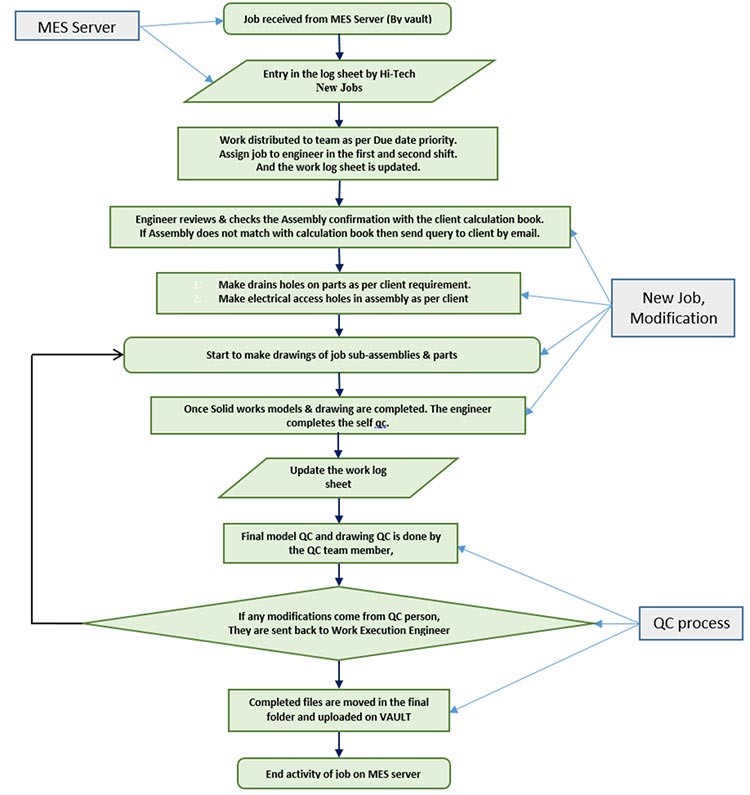

Business Needs

Challenges

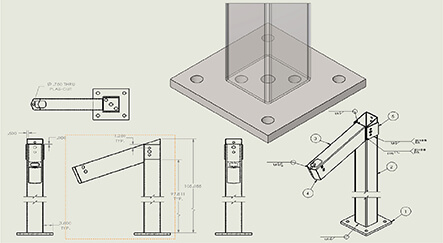

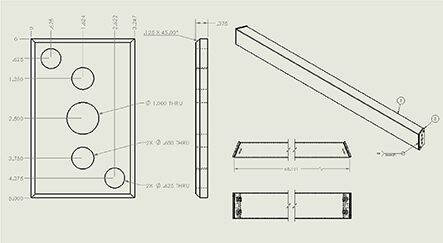

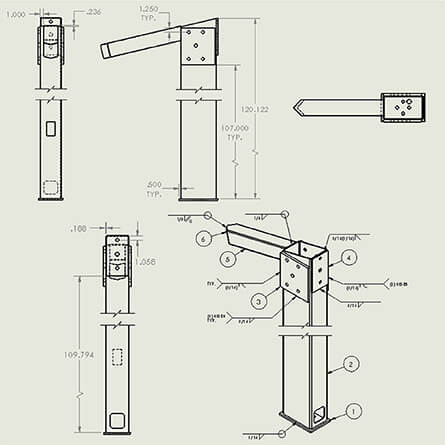

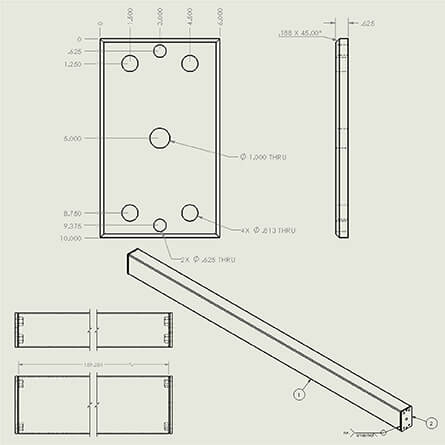

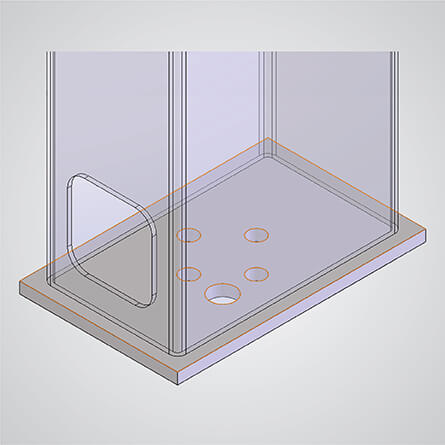

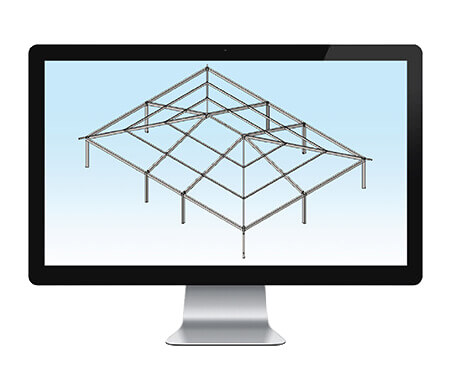

3D modeling and drafting support for multiple shelter structures

The client shared the full 3D model package in of MES server in SolidWorks format as input files. The project team also received a constant influx of inputs on the server on regular basis.