Business Needs

Challenges

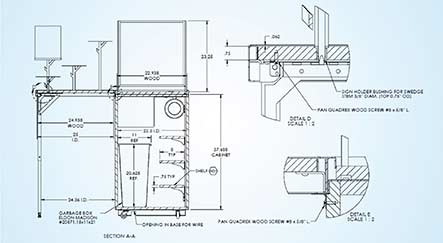

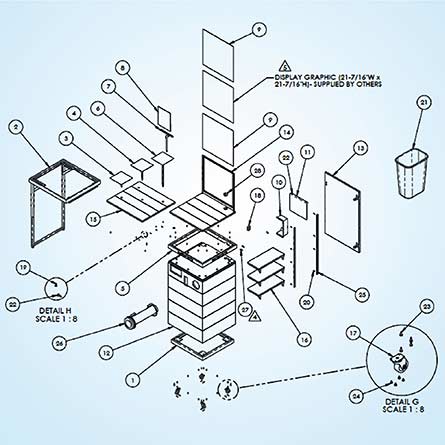

Reduce manufacturing cost and time to half for furniture manufacturing with CAD drawings and models

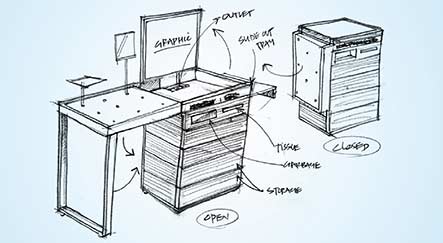

The client shared input sketches as design briefs for all display furniture which were studied by the project team to understand the design intent.