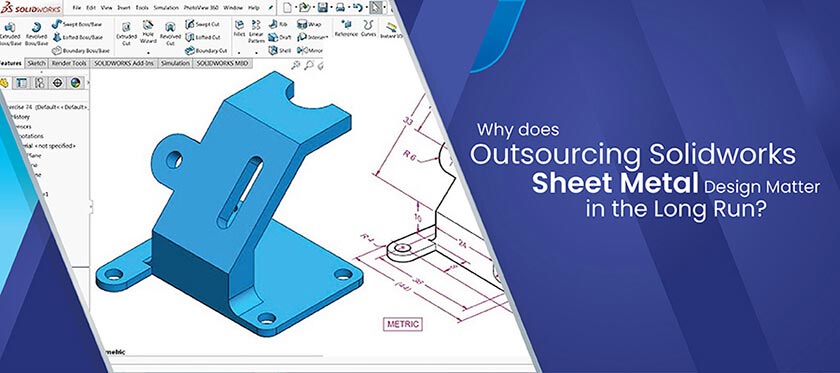

The sheet metal design industry leverages SolidWorks for its precision and efficiency in creating detailed, manufacturable 2D fabrication drawings and 3D modelling for sheet metal. Outsourcing these tasks to specialized firms enhances quality and innovation while significantly reducing costs and development time.

SolidWorks sheet metal design services enable unparalleled precision, efficiency, and innovation in the way sheet metal products are conceived, designed, and fabricated. The software suite offers a comprehensive set of tools for drafting, modeling, and detailing. By facilitating a seamless transition from digital blueprints to real-world applications, SolidWorks empowers designers and engineers to push the boundaries of what is possible in fabricated structural metal product design.

Table of Contents

As the demand for more complex and refined products grows, the need for SolidWorks design outsourcing becomes increasingly critical. Outsourcing sheet metal design to experts provides companies with the agility to adapt to market changes swiftly. Through specialized 3D modelling for sheet metal with SolidWorks, businesses can harness the full potential of this technology, ensuring accuracy and integrity in every component produced, thereby setting new standards in the sheet metal design company sector.

The sheet metal design domain is fraught with challenges that demand both precision and innovative solutions. Contractors and manufacturers in the industry face several hurdles, each affecting the final product’s quality, cost, and production efficiency.

By outsourcing to experts in a sheet metal design company, firms can enjoy enhanced design accuracy and innovation, all while achieving cost savings. Offshore CAD partners thus offer a strategic advantage, enabling businesses to navigate the complexities of sheet metal design with greater ease and efficiency.

Nail design accuracy with cost savings with an efficient SolidWorks sheet metal design partner.

Contact us now »Outsourcing SolidWorks sheet metal design to offshore experts presents a multifaceted approach to overcoming traditional barriers in design, manufacturing, and operational efficiency. Each aspect of outsourcing contributes uniquely to enhancing the overall design and production process.

The financial benefits of sheet metal part modelling due to outsourcing are immediately apparent, especially in terms of software licensing and training costs. Companies often face significant expenses acquiring licenses for specialized software like SolidWorks and Inventor, not to mention the associated costs of training staff to proficiently use these tools.

By outsourcing, businesses gain access to these resources without the upfront investment, essentially converting fixed software and training costs into variable costs that scale with project needs. For example, a small to medium-sized enterprise (SME) looking to design a new line of sheet metal products can save tens of thousands of dollars in software costs alone by partnering with an offshore design firm that already possesses the necessary tools and expertise.

This approach not only reduces capital expenditure but also diminishes the need for ongoing software updates and maintenance, further lowering the total cost of ownership. This financial efficiency enables companies to allocate their budgets more strategically to drive growth and innovation.

The dynamic nature of market demands requires companies to be able to adapt quickly, making speed and flexibility in design and production essential. Outsourcing to CAD drafting firms like Hitech CADD Services offers the advantage of time zone differences, which can be leveraged to ensure that work continues around the clock, significantly accelerating project timelines. For instance, while a company in the US closes for the day, their offshore partner in India can continue working on a 3D modelling project, effectively doubling the productivity cycle.

This global collaboration allows for a more agile response to changes in project scope or unexpected challenges, enabling companies to scale their operations up or down with ease. For example, a firm that needs to rapidly prototype a new product design can take help from an outsourcing partner to quickly allocate additional resources to meet tight deadlines.

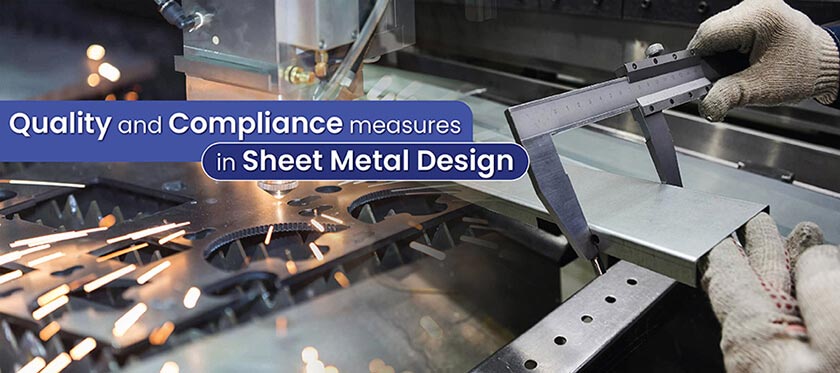

Outsourcing partners specialize in SolidWorks and are well-versed in the stringent quality standards and compliance requirements specific to SolidWorks sheet metal design. These firms ensure that every design not only meets but exceeds expectations in terms of design for manufacturability (DFM), functionality, durability, and compliance with relevant standards.

For example, a sheet metal design outsourcing project for construction equipment can streamline the product design for enhanced manufacturability but also adhere to the stringent construction industry standards. This fact demonstrates the pivotal role of outsourcing in achieving superior quality and compliance, a task that requires a deep understanding of both SolidWorks, sheet metal fabrication expertise, and industry-specific protocols.

This factor is crucial for companies looking to enter new markets or ensure that their products are compliant with international norms and aligned with quality control. This approach reduces the risk of costly redesigns or recalls. They help manufacturers navigate the complexities of compliance, ensuring smoother path to market entry.

Delegating the technical aspects of sheet metal design to offshore experts, companies can redirect their focus towards strategic growth areas such as market expansion, customer service, and product design innovation. This reallocation of resources and attention enables businesses to harness their strengths and differentiate themselves in a competitive market.

Outsourcing to sheet metal design experts allows a construction company to leverage the firm’s advanced SolidWorks sheet metal CAD services for developing complex, precision-engineered parts for multiple applications. The client is now able to focus on their core competencies that could include assessing market trends, improve customer relations, and drive eco-friendly initiatives.

Outsourcing mundane or highly technical tasks allows businesses to concentrate on building their brand, engaging with customers, and innovating their product line, which are critical components of long-term success.

Access to a global pool of talent through outsourcing introduces fresh perspectives and innovative solutions to design challenges. This diversity in problem-solving approaches can be particularly advantageous for projects requiring creative and out-of-the-box thinking. For instance, a design challenge for a new type of foldable metal furniture might benefit from the unique cultural and engineering insights of designers from different parts of the world, leading to a product that is not only functionally innovative but also aesthetically appealing to a global market.

This worldwide talent pool also means that companies can tap into niche skills and expertise that may be scarce or unavailable in their local market. Whether it’s advanced proficiency in SolidWorks, specialized knowledge in metal fabrication techniques, or experience in a specific industry sector, outsourcing provides access to experts who can bring high levels of skill and innovation to a project.

Outsourcing SolidWorks sheet metal design can help you focus on core competencies right away.

Contact us now »

Effective allocation of internal resources is another advantage of outsourcing. Companies can shift their focus and resources towards strategic initiatives, such as research and development, marketing, and customer service, while outsourcing partners handle the detailed work of sheet metal design. This ability not only optimizes the use of internal resources but also enhances the company’s ability to innovate and respond to market demands.

For example, a manufacturing company can outsource the design of a new product line’s metal components, freeing up its engineers to focus on improving production processes and operational efficiency.

Outsourcing firms typically have robust frameworks for data security and project management, significantly reducing operational and cybersecurity risks. This is crucial in industries where protecting intellectual property and sensitive information is paramount. By partnering with an outsourcing firm that prioritizes security, companies can safeguard their projects against data breaches and cyber threats, ensuring their intellectual property remains secure. In a real-life scenario, an outsourcing firm specializing in SolidWorks sheet metal design could employ encrypted data transmission and secure cloud storage to protect client designs and confidential information. Their efforts can effectively mitigate the risk of IP theft or unauthorized access.

Keeping up with the latest technological advancements can be costly and time-consuming. Outsourcing partners make continuous investments in the latest software updates, tools, and training, allowing clients to benefit from these advancements without direct investment. This access to cutting-edge technology enhances the design process, ensuring that the final products are of the highest quality and incorporate the latest innovations.

For example, a company specializing in consumer electronics decides to outsource its sheet metal design projects to a partner skilled in SolidWorks Design Outsourcing. This strategic move grants them immediate access to the latest versions of SolidWorks, equipped with cutting-edge features that streamline the design of complex metal casings and components crucial for their products. The outsourcing partner enables the electronics manufacturer to integrate advanced design techniques without having to bear software licensing costs, updates, and training for specialists.

The complexity of sheet metal design, with its intricate details and specifications, can be overwhelming for in-house teams lacking specialized expertise. Outsourcing firms specialize in managing and simplifying complex design tasks, ensuring that even the most challenging projects are executed efficiently. Their expertise in navigating the complexities of sheet metal design, from understanding material properties to applying advanced fabrication techniques, makes them invaluable partners in bringing complex projects to fruition.

For instance, an outsourcing firm tackles a project for an automotive manufacturer needing complex, lightweight sheet metal components. With their expertise in SolidWorks and sheet metal CAD design techniques, the firm successfully simplifies the design process, ensuring the components are both manufacturable and meet the rigorous safety standards of the automotive industry.

Finally, outsourcing provides a solution to the expertise gaps that many companies face in specialized areas of sheet metal design. Whether it’s adjusting k-factors, calculating bend radii, or optimizing designs for manufacturability, outsourcing partners offer a depth of knowledge that can significantly enhance the quality and efficiency of the design process. This access to niche expertise allows companies to tackle projects that would otherwise be beyond their in-house capabilities, ensuring that every aspect of the design is optimized for performance and manufacturability.

An outsourcing partner, skilled in SolidWorks sheet metal design, can optimize these parameters for a unique, curved metal bench intended for public parks. The precision in k-factor adjustments and bend radii calculations are critical for ensuring the furniture’s aesthetic appeal and structural integrity.

Leverage the depth of knowledge and niche expertise of your sheet metal design partner today.

Contact us now »Hitech CADD Services a leader in SolidWorks sheet metal design services, offers a comprehensive suite of solutions tailored to the unique needs of the manufacturing industry. Here is why you should outsource sheet metal design to Hitech CADD services:

Hitech CADD Services recently streamlined the design process for a building products manufacturer by adhering to DFMA guidelines, reducing turnaround time by a whopping 56%. Know more about our CAD drafting for sheet metal Design Project.

Their track record of success is evident in the substantial benefits delivered to clients, including improved design accuracy, reduced production costs, and significantly shortened development cycles.

Outsourcing SolidWorks sheet metal design offers strategic advantages beyond cost savings, integrating global expertise, innovation, and operational efficiency. Companies gain access to specialized skills and technology, enhancing design accuracy and manufacturability without hefty investments. This approach allows for flexibility and scalability, ensuring rapid adaptation to market demands while maintaining high quality.

Moreover, SolidWorks design outsourcing frees companies to concentrate on core activities and growth and shift resources towards innovation and market expansion. This strategic shift streamlines operations and fosters a culture of continuous improvement. Outsourcing is a strategic choice that propels businesses forward, leveraging global talents and technologies for superior outcomes.

You may also like

From 2D to 3D: Why Architects are Switching to BIM Modeling