A team of four Inventor engineers with knowledge in marine furniture fit-outs was assembled. Once the input drawings were received, the team studied the plans and acquire knowledge for specific standards.

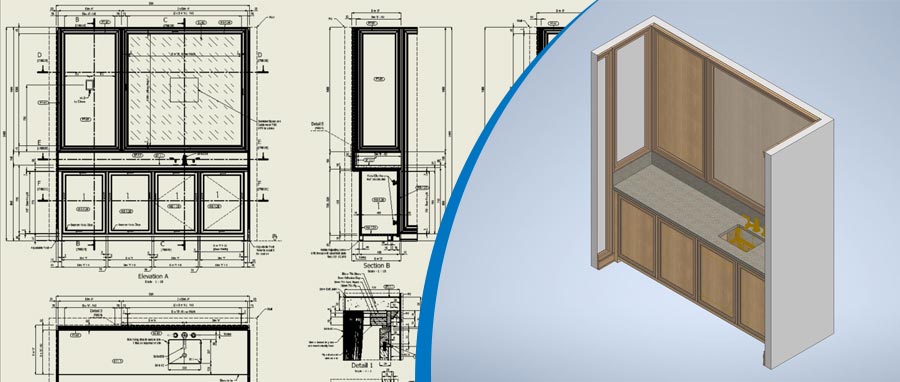

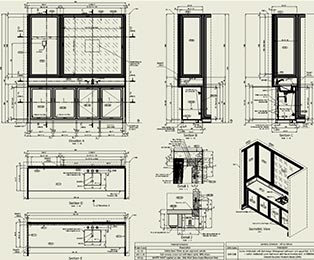

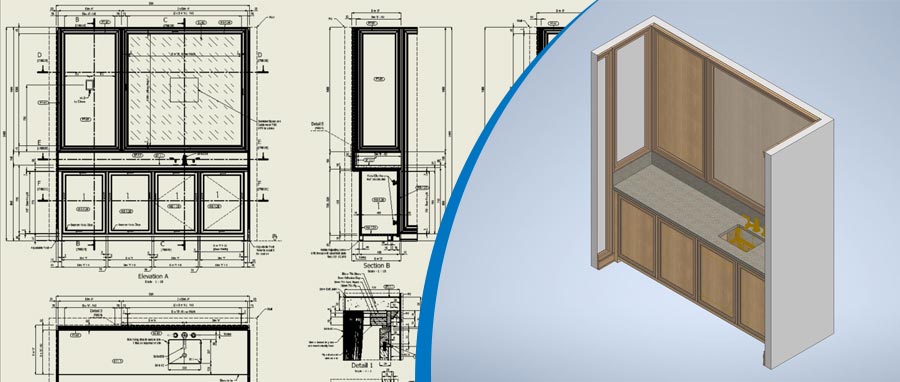

CAD Drafting for Vanity

CAD Drafting for Vanity

- A rulebook was prepared to ensure that all standard practices for 5 POCs were documented and strictly followed

- A daily standup meets between client POCs and our project team were arranged to get onboard with client’s practices, get in sync with expectation and fix errors whatsoever

- Initial RFIs were raised to understand the architect’s design intent for all fit-outs and yacht furniture products

- The team arranged a pre-drafting meeting before Inventor drafting began to avoid rework and understand the exact expectation from each drawing

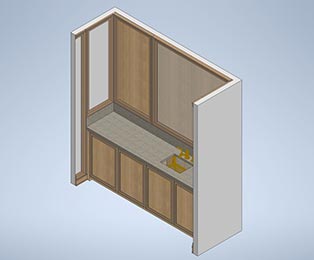

- Location and placement of all equipment were understood and cabinet layouts were decided

- Details like drawers, handle design, sliding doors, hinges etc. were decided and finalized with client using Woodwork for Autodesk Inventor

- Equation based iLogic was used to modify and customize assemblies to auto-reflect changes in geometry across the assembly

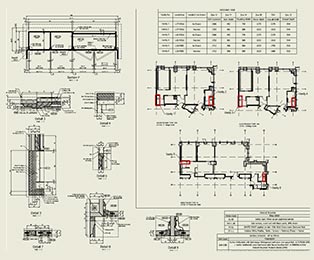

- Installation drawings and assembly drawings were also created to assist foremen on the site

- The project team used standard products from the CAD library wherever available along with filler material to ensure meeting the space allocated

- Upon agreement final furniture shop drawings were generated from these models with manufacturing details

- Pre-delivery calls were set up before shipping the final deliverables to the client for final approval and make on the go changes

- 90% of design changes were avoided , and the rest 10% accounted for changes originating during manufacturing shop floor or from the end client

- Final drawings were developed with clearly areas, dimensions, tolerances and allowances for hardware