Business Needs

Challenges

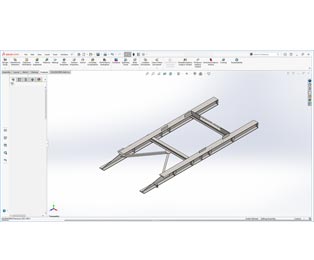

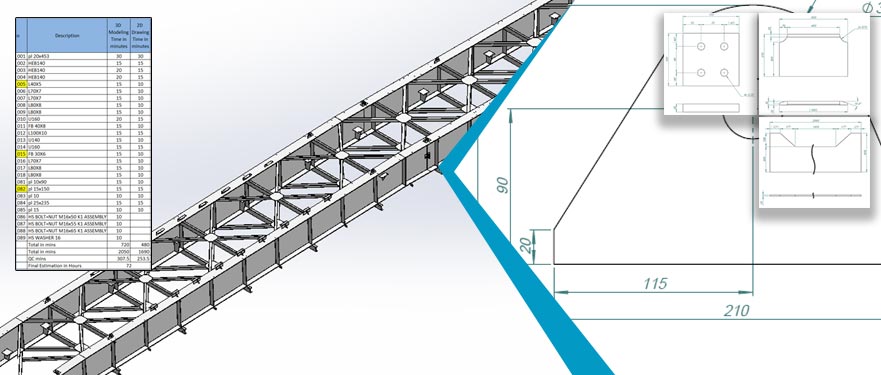

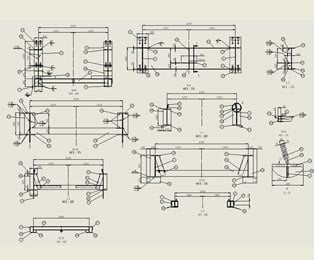

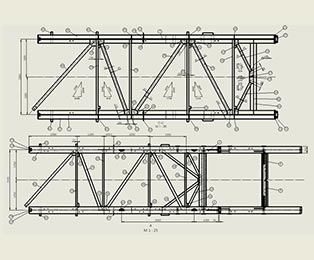

Streamline metal fabrication with detailed CAD drafting

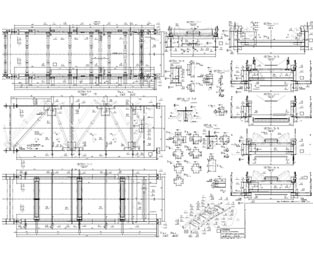

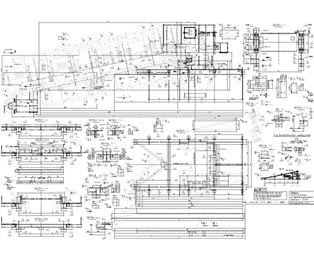

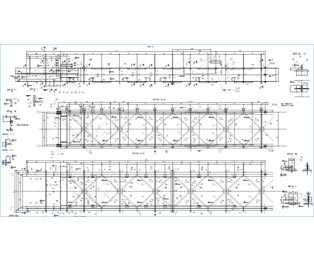

The client’s customers shared 2D PDF drawing files with BOMs which were given as inputs to Hitech CADD Services’ project engineers. As these files were stuffed with information, the team began by extracting necessary and accurate information.

The entire project was accomplished through a hierarchical model of a senior project engineer leading a team of four design engineers. They successfully delivered high-quality models across the project lifecycle.