A team of six AutoCAD engineers with expertise in cabinet design drafting was assembled. After we received the architect’s drawings as inputs, team had an in-depth studied of the drawings.

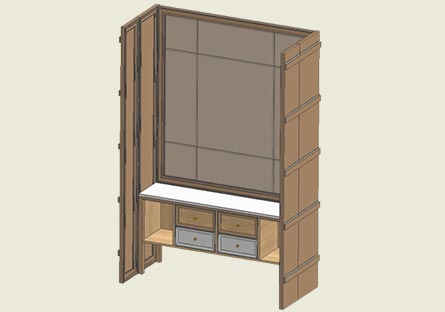

- Project team started by understanding the design intent and manufacturing inputs

- They also studied placement of every product such as cabinets, service tables, ovens etc. and distances between each product and kitchen section were planned carefully

- Design detailing like need for drawers, handle design, sliding doors, hinges etc. were communicated with the client as well as the end customers to initiate development of detailed drawings

- A POC was assigned to facilitate seamless communication between the client, Hitech teams and the end customer who consulted to select appropriate joineries

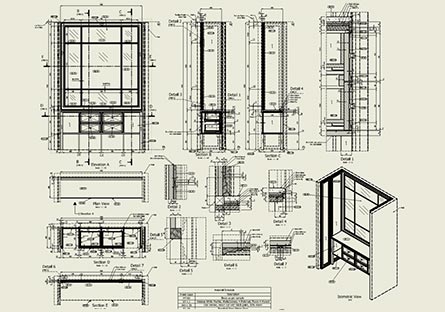

- Final drawings had clearly defined sections, tolerances, allowances and need for hardware along with interpretation drawings

- The project engineers took care of basic aesthetical parts such as avoiding damage to walls by hinges, vanities underneath the basins etc. All revisions were addressed using red markups.

- Initial RFIs were raised and all details for bought out parts like hinges, runners, handles, leg support, caster wheel detail etc. were enlisted in the BOMs

- Blocks of all standard products were readily available in AutoCAD library which were used to save modeling time

- Final shop drawings, elevations, floor plans and sections were generated from these models with details for items like cabinets, doors, wardrobe, etc. were converted to AutoCAD dwgs. files

- Strict QC was done for all dwgs. prepared against the architect’s drawings and markups shared by senior engineer