Business Needs

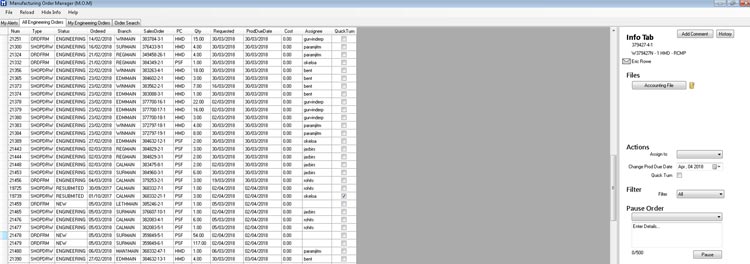

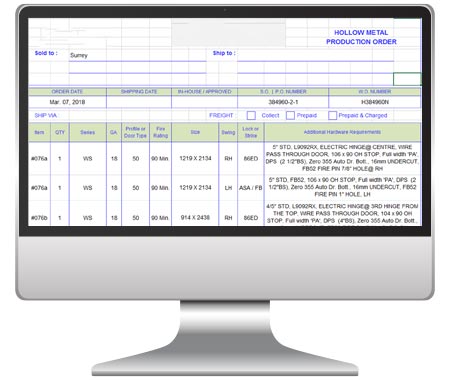

The client was looking for growth and expansion of their firm and needed to increase the volume of bids along with high accuracy. But current legacy methods for cost estimation were erroneous for multi-component doors-window manufacturing projects and needed acceleration.

Challenges

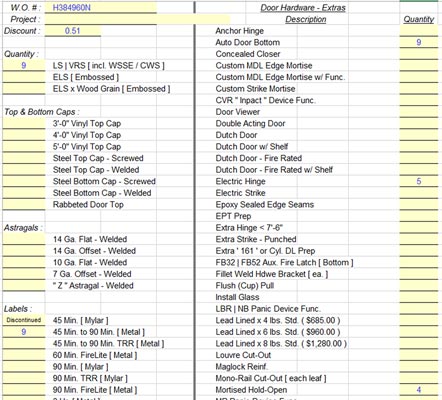

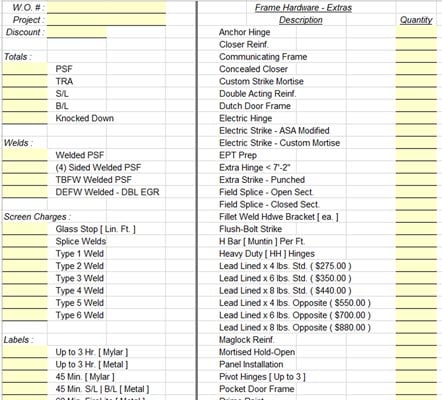

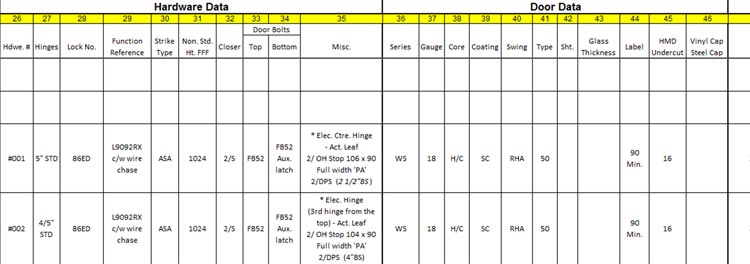

Get accurate quantity takeoff and place the bids confidently

The client shared architectural input drawings of the construction project to calculate the number of doors, frames, windows, sidelites, transom, open case, and hardware both normal and fire rated made of metal and wood. It demanded having sound knowledge of specialty doors and windows like soundproof, bulletproof, fire rated, and other special products.