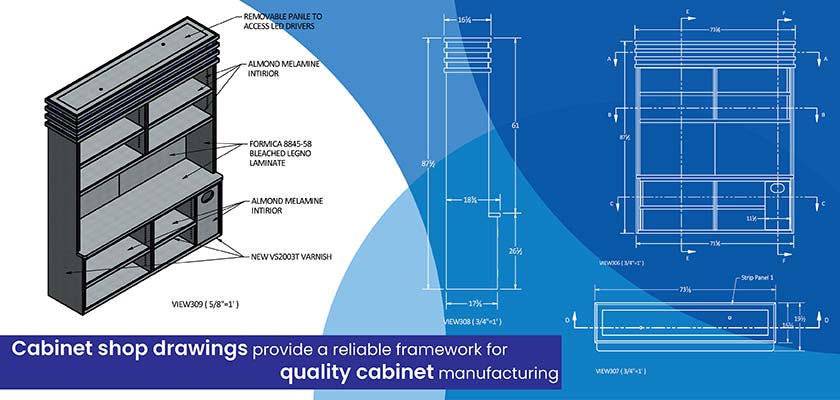

Cabinet shop drawings convert design intent into instructions illustrating how the cabinetry will be built. They include elevations, sections, material specifications, details on hardware and installation, and assembly drawings. These drawings prevent communication problems and other issues improving material usage and providing quality cabinetry.

Cabinet shop drawings are the blueprints of a cabinet project that help you convert your design intent into accurate instructions for fabrication. When creating custom cabinet drawings, you should be observant of dimensions, material, joinery, and hardware specifications.

In cabinet shop drawings you need to provide elevations and sections with dimensions. It should also address the materials such as wood species and the finishes. These drawings also define custom joinery methods and hardware placements so that all documented design considerations match the client’s expectations.

Table of Contents

Cabinet shop drawings are very comprehensive millwork shop drawings that guide or illustrate how to manufacture and install cabinetry. These drawings are the planning of the actual product to be constructed.

Cabinet shop drawings provide a set of specifications for all dimensions, materials, joinery, hardware, and finishes needed for the cabinetry. In order to create these drawings you can use software such as Microvellum which assist you with specific tools for woodworking.

Cabinet shop drawings operate as instruction manuals for building cabinets, so everyone has the same instructions, from designer to manufacturer to installer. This reduces sources of confusion surrounding the project and also confirms that the built product match the design intent for functionality and purpose.

There are two kinds of cabinet shop drawings that drive projects forward:

Get custom cabinet designs tailored to your unique requirements.

Request a design »The cabinet shop drawings provide:

Ensure perfect cabinet manufacturing with our 2D shop drawings

Contact us now »

Cabinet shop drawings should include the key elements that provide a complete understanding of the cabinet specification, construction and installation.

To provide a full picture of the cabinet, various views are helpful, with each view showing a different perspective:

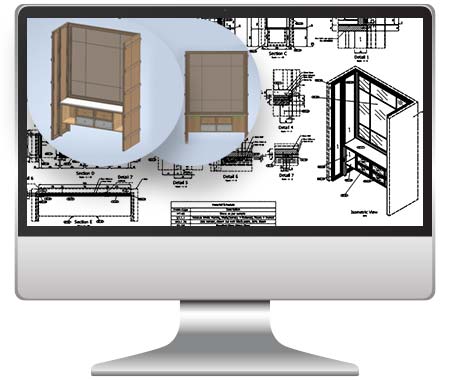

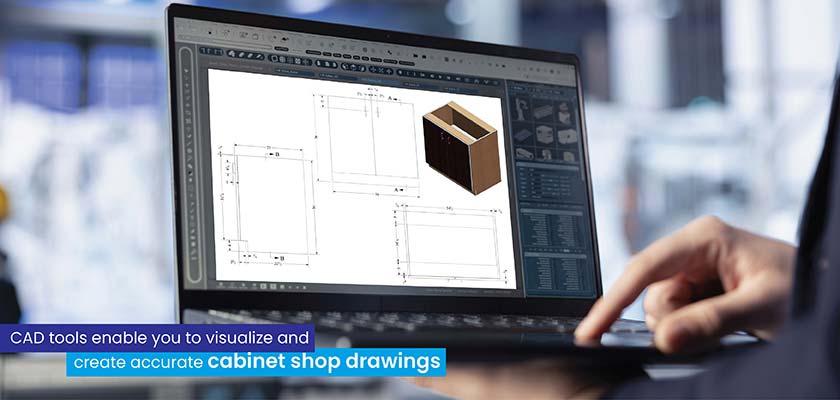

CAD programs like SolidWorks is ideal for making cabinet shop drawings and showing cabinet makers several views of the components, all at once, from all directions before the actual build begins.

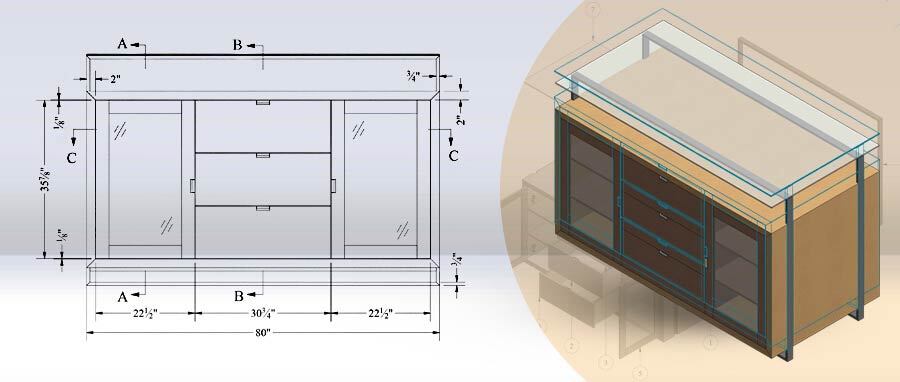

Dimensioning is crucial to cabinet shop drawings and errors in even the smallest dimension may cause major problems in the manufacturing and installation.

Elements you should consider for dimensioning cabinets:

To eliminate reworks after fabrication we also include detail specifications and measurements of the space of installation (in as-built dimensions). CAD tools like Cabinet Vision make this much easier as you can use it to automatically calculate the dimensions of the product and apply them to show you a perfect fit.

Choosing the right materials is key to successfully achieving the aesthetics. When you specify materials correctly in the drawings it results in improving durability and performance of the cabinetry.

Material specifications in shop drawings should include:

Hardware is also an important element in terms of the functionality, and form of cabinetry. Shop drawings need to include hardware lists that contains manufacturer names, part numbers, quantities, and finishes.

It is important to define what type of hinge, hinge size, hinge location, and any hinge angles required in order to achieve the desired overlay for the door. Specify if the drawer slide is telescoping or not (using the types of slides will determine how much weight or load the slides are rated to handle).

Also indicate if the slide has a closing mechanism built in. Be sure to specify the type of pulls or knobs (style, finish, mounting centres) for intended ease of use and design.

Software like SolidWorks allows the designer to specify the hardware in a cabinet shop drawing easily for more accurate placement.

Proper assembly instructions are essential to ensure an efficient installation process. To that end, you should include detailed assembly instructions in your shop drawings.

Streamlining cabinet manufacturing bids with automated quantity take-offs

3D CAD Model of Kitchen Cabinet

3D CAD Model of Kitchen Cabinet

A US based kitchen cabinet manufacturer was interested in improving the accuracy and efficiency of their estimating and bidding process for high end luxury kitchen projects. Their goal was to develop precise quantity takeoffs (QTO) and cost estimating from architectural drawings for them to secure more bids.

Hitech CADD Services produced layout drawings and 3D models using 2020 Design. We developed macros in Excel spreadsheets, for a few materials, like veneers, cabinet boxes and different woods, to calculate quantities. These Macros greatly reduced the amount of manual effort and mistakes in estimating

This resulted in:

Stay Ahead with the Latest Kitchen Cabinet Trends in Millwork Drafting

Millwork drafters must continually refine their skills to keep pace with evolving kitchen cabinet styles, materials, and drafting technologies. Our white paper, “Top Kitchen Cabinet Trends Influencing Millwork Drafting Plans,” provides expert insights to help you stay competitive in the industry.

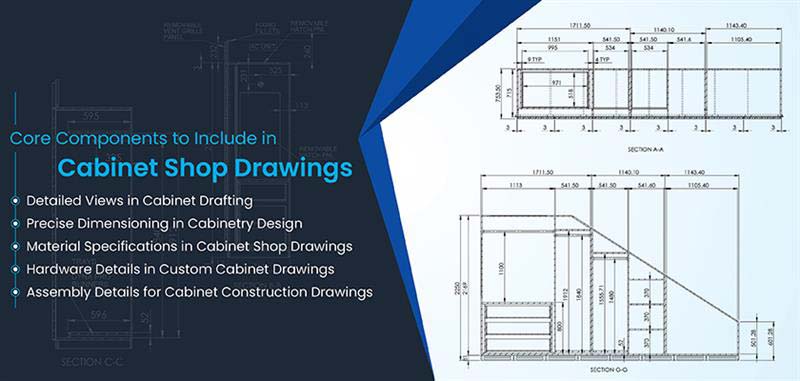

While shop drawings are generally supported by the core components of the drawings, advanced design considerations make the drawings smarter, more efficient, and manufacturing friendly.

Cabinet details should include cut lists, grain direction markers, and nesting layouts to optimize the use of material. Export drawing in CNC compatible format with the tool paths and cutting data, so that the data flows seamlessly into the shop. Such workflows are especially critical for institutional and museum casework.

Using tools like 2020 Design you can create cabinet drawings that integrate easily with manufacturing systems.

Keep in mind:

Well written concise notes give you clarity on construction details, emphasize critical dimensions and outline installation conditions. You must use a standardized layer naming system to help others read the drawings.

And to make sure that everyone is working from the most up to date drawings you need to establish a proper revision control system. This means monitoring revisions, documenting approvals and managing changes throughout the project completion.

The process for producing cabinet shop drawings is very thorough. Here are the steps that you need to follow:

Step 1: Gather design specification and client requirements First you need to gather all the project information, design approaches, client requirements, measurements of the space and any functional requirements which all serve as the basis of the drawings.

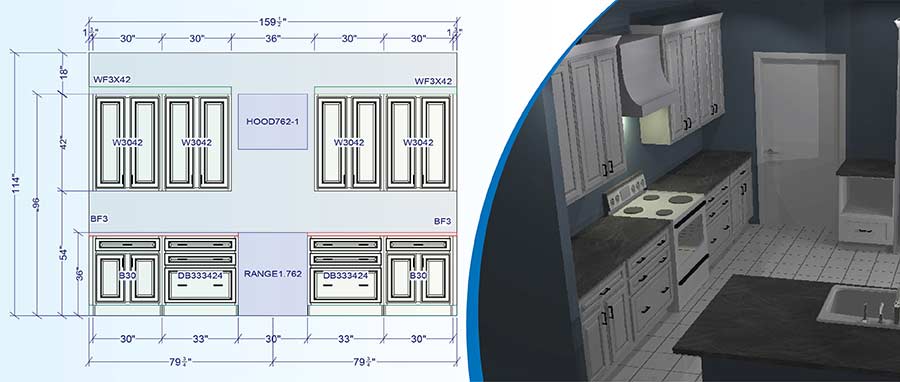

Step 2: Define overall dimensions and scale of the drawings It is important to establish overall cabinet dimensions and a scale throughout the drawings. Detailed measurements are important, if you want to avoid issues during manufacturing and installing the cabinets.

Step 3: Specify material and hardware You should indicate which hardware, hinges, drawer slides and pulls are being used and their specifications. For library cabinets and bookcases, you should be specifying materials, adjustable shelving hardware, reinforced load shelving and integrated lighting.

You need to indicate where the hardware will be located and what materials will be used which may include wood species, sheet goods and edge banding.

Step 4: Develop the required views (elevation, section and plan) Develop views of cabinetry in detail, plan views, elevations and sections. These views contain a full cabinet descriptive presentation, dimensioning and internal structure of the cabinets.

Step 5: Verify errors and industry standards compliance The drawings should be checked for errors and consistency. Compare the drawings to industry standards and best practices to ensure quality and consistency.

If you follow all of these steps you will have cabinet shop drawings that are accurate and complete for the entire manufacturing process.

Offshoring cabinet drafting reduces turnaround time by 50%

Cabinet CAD Drafting for Furniture Manufacturer

Cabinet CAD Drafting for Furniture Manufacturer

A residential furniture manufacturer based in the US had a backlog of cabinet design projects. The manufacturer needed detailed kitchen cabinet manufacturing drawings to improve turnaround time (TAT) and alleviate skill shortages in-house.

Hitech CADD Services consigned AutoCAD engineers who created detailed manufacturing drawings to ensure product placement, measurements and hardware specification accuracy. A dedicated point of contact made sure of seamless communication between the client, the Hitech CADD Services team and end customers.

The deliverables were:

Even with planning ahead, errors can find their way into cabinet shop drawings which can waste your time and money. Here are some common errors to avoid:

Bring your kitchen ideas to life with expert cabinet shop drawings.

Get cabinet drafts »

Cabinet shop drawings include more than simply the parts. To ensure that you maintain clarity, efficiency and accuracy throughout the process it is important that you follow the best practices while creating them.

Want to visualize your cabinet designs in 3D before fabrication?

Talk to our CAD specialists Now »Faster cabinet shop drawings development using 2020 Design

I Shape Kitchen

I Shape Kitchen

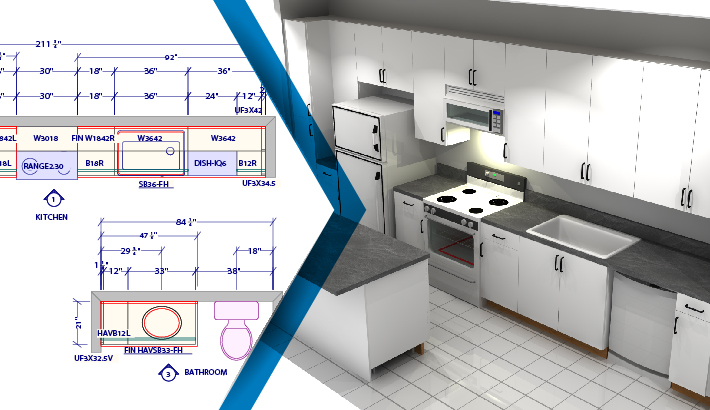

A US frameless kitchen and bath cabinet manufacturer needed to improve their design visualization and manufacturing efficiency with 3D models and shop drawings derived from 2D layouts.

Hitech CADD Services used 2020 Design to leverage 2D drawings into 3D models of the cabinetry, and visualization of kitchen and bathrooms layouts. The team employed drag-and-drop capabilities with the software product library to enhance the speed of developing designs by ensuring correct calculations of all the project components including vanities, hardware, accessories and countertops and all.

The results were:

Improved manufacturing of cabinetry by integratingAutoCAD and Imos IX

Input: Kitchen layout with red line mark-up

Input: Kitchen layout with red line mark-up

A US residential furniture manufacturer was looking to modernize their cabinet production and turn out high quality cabinet shop drawings utilizing CAD integration. The client needed high quality cabinet shop drawings continuously so they could manufacture cabinets effectively.

Hitech CADD Services assigned a capable team of CAD drafting professionals in furniture detailing and CNC machine coding. The team worked with the client closely to understand their architectural plans and developed cabinet shop drawings accurately using AutoCAD and Imos IX.

This resulted in:

We can expect more automation of the drafting process in the future. With the help of AI, you will be able to create better and efficient shop drawings. This will speed up the drafting workflow and reduce manual work.

Augmented Reality (AR) and Virtual Reality (VR) will change design and review processes. Seeing cabinetry designs in real time with clients and manufacturers prior to production, will give immersive visualization of cabinet concepts in real time, and in actual locations. These technologies will make using cabinet shop drawings more accurate, efficient and communication centric.

Producing quality cabinet shop drawings is importantfor creating successful cabinetry. It truly is about accuracy, clarity conveyed through proper use of these drawings. Use specialized CAD software to simplify complex aspects in technical drawings, show as many detailed views and specification as needed for a good understanding. Always, follow the best practices for creating cabinet shop drawings.

By leveraging technology and collaboration, you will be able to produce good shop drawings to reduce errors. And outcome is cabinetry that is beautiful, functional and represents your client’s vision.

Approval drawings are the ones that are sent to clients and architects for getting their consent before starting fabrication. Complete shop drawings are the ones you actually refer to for manufacturing. These can be simple blueprints or detailed based on your project.

A cabinet shop drawing must have plan views (top), elevations (sides), sections (concealed), isometric/3D views (overall) and close up details of complex features.

If your dimensions are not correct, your manufactured parts will carry these errors. This will lead to ill-fits, clearance issues and faulty parts.

Besides the diagrams, good quality cabinet shop drawings should have details of joinery methods, fastener types, fastener locations, and special assembly notes if any.

Outsourcing cabinet shop drawings frees your workforce to focus on other core areas. Also, when you outsource you gain access to experts and specialized tools who help reduce turnaround times for your design projects while keeping them accurate.

You may also like

BIM-Based MEP Coordination for Multi-Trade Collaboration

How AI and ML are Shaping the Future of Scan to BIM