Business Needs

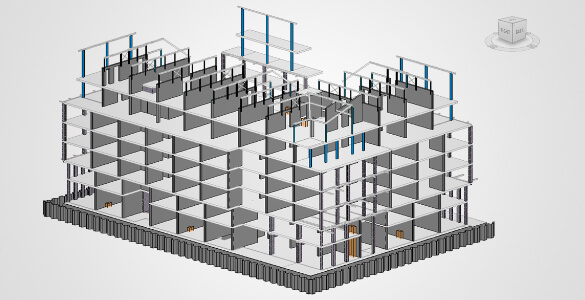

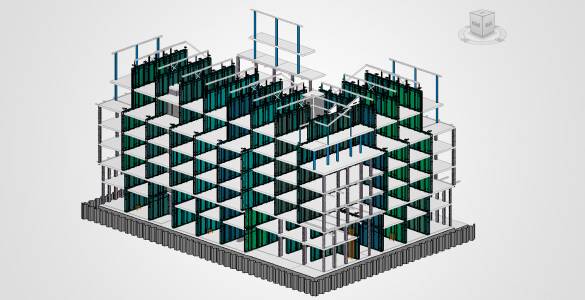

A leading formwork production company situated in Netherlands, faced challenges of getting accuracy in modelling formwork for 22 storeyed commercial building. They needed accurate 3D models of formwork in BIM 360 along with general arrangement fabrication drawings (GA’s) with part count which showed the overall structure or composition of the building.

Challenges

Accurate 3D models of formwork in BIM 360 along with general arrangement fabrication drawings.

The deliverables to client included:

This assisted the client company to make their production more cost-effective. Earlier they had a manual BIM ecosystem, which was not accurate and showed a 20% gap.

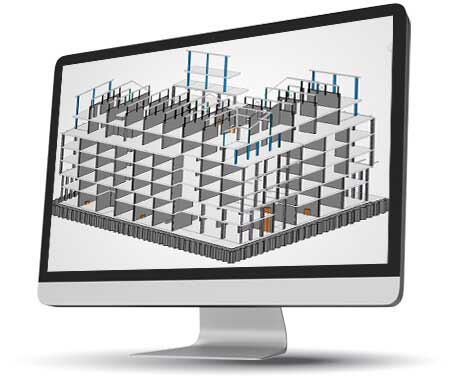

With the daily data sent to client in BIM 360 and Revit in cloud platform, they were able to access it anywhere on any device and jump into production right away.