Business Needs

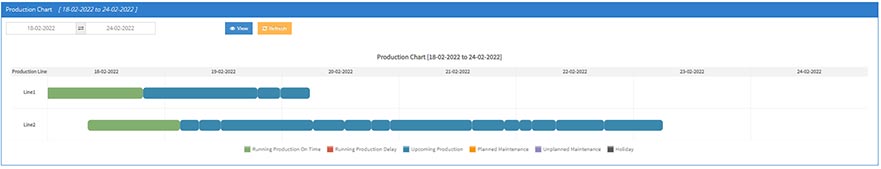

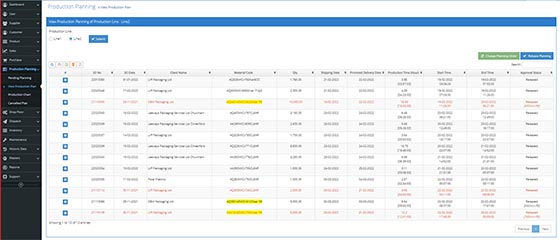

The RPET sheets specialist had no real-time visibility of manufacturing processes, stock availability and production capacity.

They needed to:

Challenges

Delivered a customized solution to digitize the entire manufacturing value chain, smoothen vendor management and eliminate manual intervention.