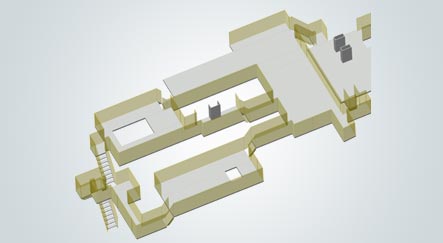

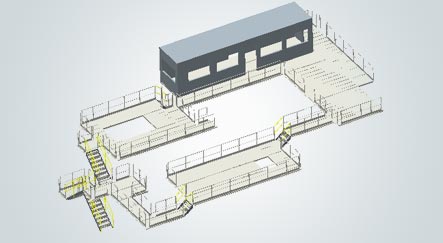

Business Needs

Challenges

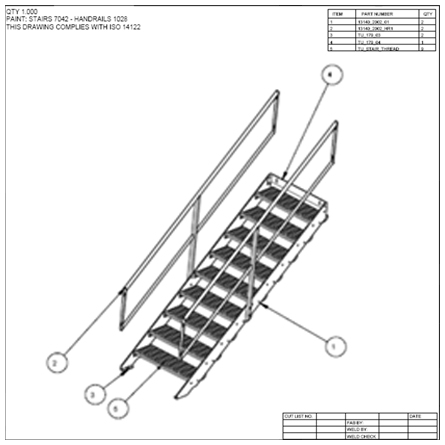

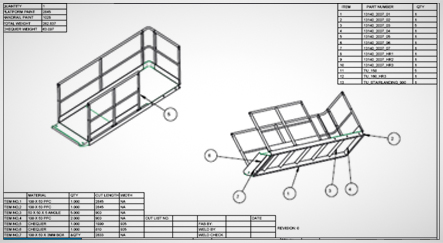

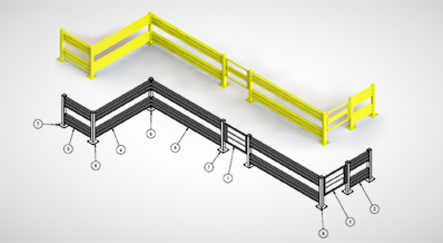

Avoided reworks in manufacturing and saved design time with top-down design approach abiding all guidelines.

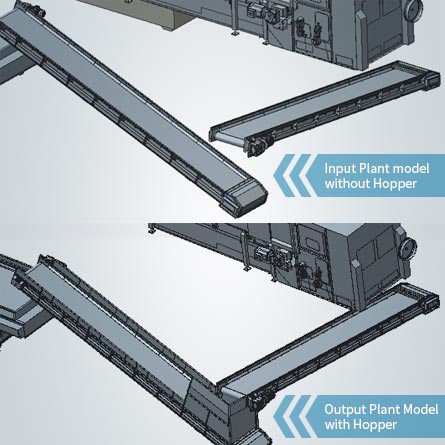

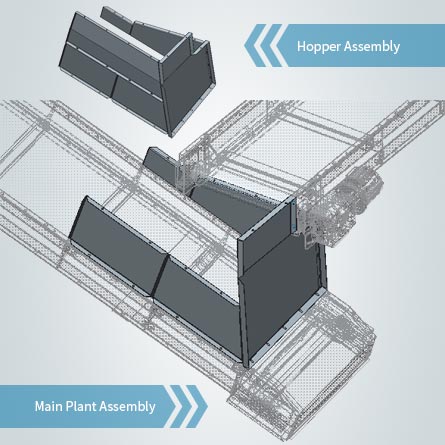

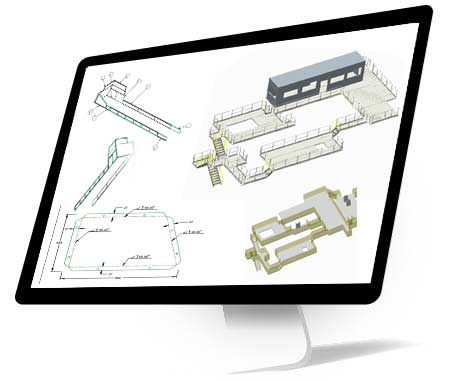

With extensive knowledge of Creo and domain expertise in sheet metal designing, project engineers at Hitech CADD Services learned the design requirements for both walkways and hoppers. Scope of work, plan of action, and milestones were defined to stay on track with delivery timelines, costs and quality standards.

The project head and coordinator ensure delivery of high-quality models and drawings on time through zip files over emails