Business Needs

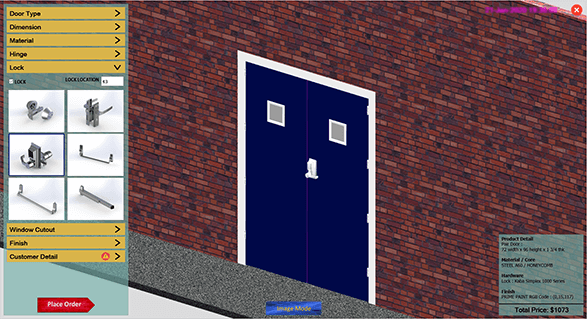

A manufacturer of hollow metal doors and frames from the USA needed to streamline their currently prevailing haphazard means of using paper-based spreadsheets and phone calls to address customer inquiries.

Challenges

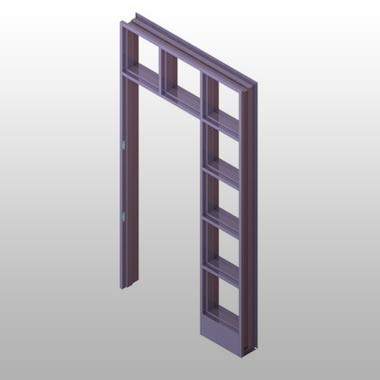

Developed Door Configurator using DriveWorks and achieved faster response to client enquiry.

Our DriveWorks specialists teamed up with the client’s design engineers to help increase productivity by becoming lean in their ETO (Engineer to Order) manufacturing practices.

The custom 3D CAD modeling and manufacturing drawings enabled faster response to inquiries and reduced capital expenditure with 70,000+ doors designed. The quality improved by 99% and reduced design cycle time by 70% that empowered the manufacturer to improve on cost of production and achieve higher customer satisfaction.