Manufacturers must accurately meet diverse client needs to maintain a competitive edge. DriveWorks automates and accelerates custom industrial shelving and rack system designing with rules-based design and parametric modeling.

In custom industrial manufacturing, what differentiates a manufacturer from the rest of the crowd is TAT and level of customization. One area where this holds true is in the design of custom industrial shelving and rack systems.

Table of Contents

Traditionally, process of customizing designs has been labor-intensive, time-consuming, and prone to errors. However, with advancements in technology, especially automation, design automation tools like DriveWorks enable a faster design customization with minimal manual intervention.

DriveWorks is a powerful CPQ or a visual configuration tool engineered to streamline and accelerate the design process. Specifically tailored for industrial applications, DriveWorks design automation enables manufacturers to automate the creation of configurable rack systems through intelligent rules-based design. By leveraging parametric modeling and predefined rules, DriveWorks eliminates the need for manual intervention, reducing design time from weeks to mere minutes.

Shelves can be classified into different types based on rack arrangement including, pallet racking, cantilever racking, sheet and board racking, and vertical racking. Some challenges related to shelve designs include:

Streamline your custom design workflows with our DriveWorks engineers.

CONSULT THE EXPERTS »

DriveWorks offers several key features that set it apart as the premier choice for rack system design automation in the industrial sector. Firstly, its intuitive interface allows users to quickly define design parameters and rules, facilitating rapid iteration and customization. Moreover, DriveWorks seamlessly integrates with existing CAD systems, ensuring compatibility and ease of implementation. Additionally, DriveWorks’ robust 3D modeling capabilities enable manufacturers to visualize and validate designs before production, reducing costly errors and revisions.

Customization is a hallmark of modern industrial manufacturing, and DriveWorks excels in this regard. By enabling rule-based design automation, DriveWorks empowers manufacturers to effortlessly customize rack systems to meet the unique needs of their clients. From adjusting dimensions to specifying material types, DriveWorks provides unparalleled flexibility, allowing manufacturers to deliver tailor-made solutions without compromising on efficiency or quality.

Accuracy is paramount in industrial design, and DriveWorks excels in ensuring precision throughout the design process. By automating calculations and enforcing design rules, DriveWorks minimizes the risk of errors and inconsistencies, resulting in high-quality, reliable rack systems. Moreover, DriveWorks’ parametric modeling capabilities enable real-time updates and adjustments, ensuring that designs remain accurate and up-to-date.

3D modeling plays a crucial role in the configuration of racking systems, enabling manufacturers to visualize designs and identify potential issues before production. DriveWorks enhances this process by seamlessly integrating 3D modeling capabilities into its automation workflow. Through intuitive visualization tools and dynamic rendering, DriveWorks empowers designers to create immersive, lifelike representations of rack systems, facilitating better communication and collaboration throughout the design process.

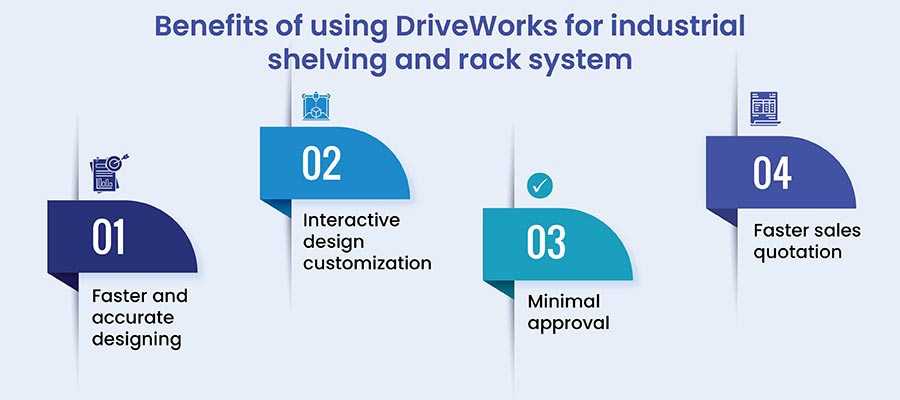

For manufacturers of storage racks, incorporating DriveWorks into their design workflow offers a multitude of benefits.

The benefits of DriveWorks in industrial shelving and rack system design are manifold. By automating repetitive tasks and enforcing design rules, DriveWorks streamlines the entire design process, resulting in significant time and cost savings. Additionally, DriveWorks’ flexibility and scalability make it ideal for handling large volumes of designs, ensuring that manufacturers can keep pace with growing demand without sacrificing quality or efficiency.

DriveWorks is uniquely suited for the design of custom rack systems, offering unparalleled flexibility and adaptability. By enabling rule-based design automation, DriveWorks empowers manufacturers to quickly and efficiently customize rack systems to meet the specific needs of their clients. Whether its adjusting dimensions, specifying materials, or incorporating unique features, DriveWorks makes it easy to create tailor-made solutions without the need for manual intervention.

In conclusion, DriveWorks represents a paradigm shift in industrial rack system design automation. By leveraging intelligent rules-based design, parametric modeling, and advanced 3D visualization, DriveWorks design automation for furniture manufacturers streamline their design processes, increase efficiency, and deliver custom solutions with unparalleled speed and accuracy. With DriveWorks, manufacturers can gain a competitive edge in the market, meeting the evolving needs of their clients while driving innovation and growth in the industry.

You may also like

From 2D to 3D: Why Architects are Switching to BIM Modeling