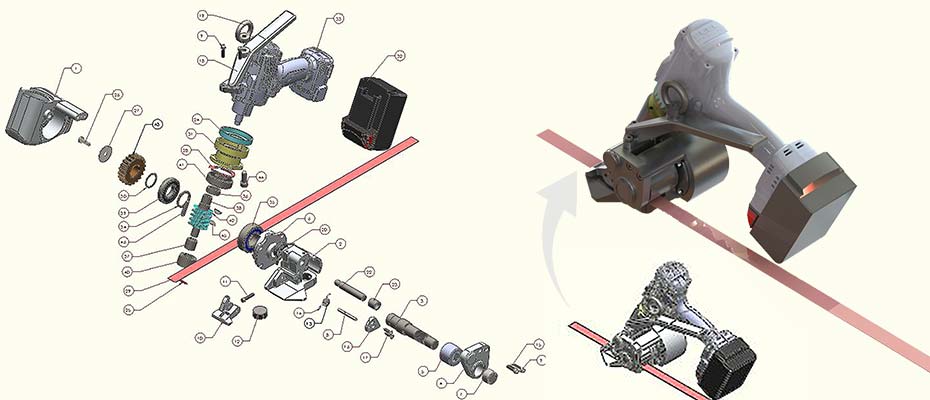

To reverse engineer the steel strapping machine prototype, a comprehensive approach was adopted combining advanced scanning techniques with manual analysis to ensure an accurate and optimized redesign.

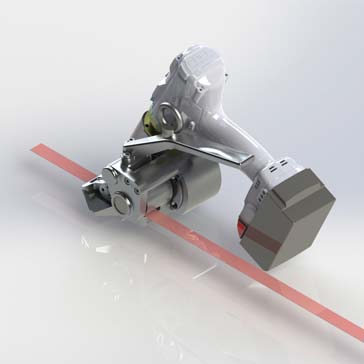

Pneumatic Tensioner Steel Strapping Machine

Pneumatic Tensioner Steel Strapping Machine

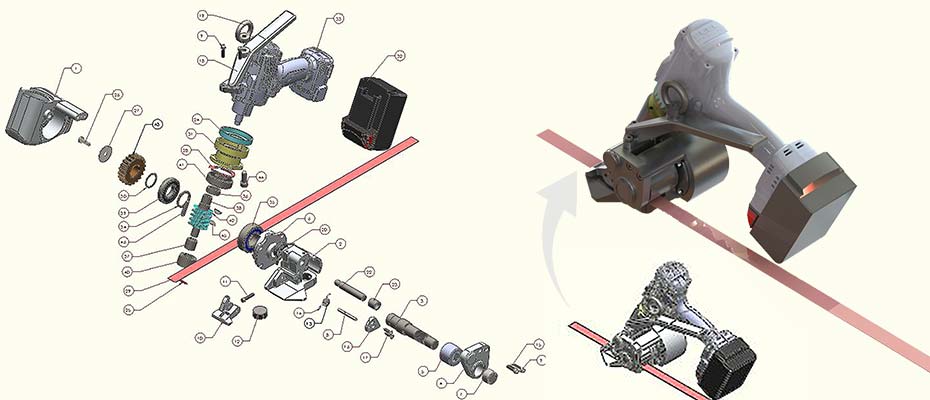

- The steel strapping machine prototype was transformed into a digital CAD model using 3D scanning techniques and manual measurements.

- Individual components were disassembled, and respective geometrical information was recorded to obtain the accurate overall design of the machine.

- Individual component drawings, as well as detailed manufacturing drawings, were prepared.

- Components were analyzed separately for structural integrity and stress concentration to identify critical areas in the design requiring optimization.

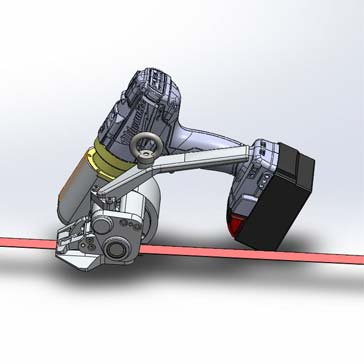

- Based on the analysis, it was observed that two of the machine components required design modification to sustain stress levels experienced during machine operation.

- Design modifications were implemented, resulting in a new machine design with improved ergonomics and enhanced strength to withstand operational loads and prevent premature failure.