The two most recommended 3D CAD software, SolidWorks and Autodesk Inventor, offer a range of features for 3D CAD modeling. Given the difficulties in selecting the right tool for your project, we have written a comparison between SolidWorks and Inventor that might help you.

SolidWorks and Autodesk Inventor are two undisputed market leaders in 3D CAD modeling software. With both having many similar features, designers and manufacturers often face the quandary: Which to use, SolidWorks or Inventor?

While some design engineers and manufacturers prefer the user-friendless of SolidWorks, others find Inventor as a more preferable tool for its functionalities. From a user perspective, both, Autodesk Inventor and SolidWorks, have their own set of features for different capabilities whether it is about:

Other features such as generative designing capabilities play a critical in selecting the CAD tool’s suitability for projects. If you look at the two closely, there are some differences that will guide you in selecting the one over the other.

Table of Content

Inventor, an Autodesk product, is a forerunner in mechanical designing, tool making, plant construction and sheet metal processing. It enables users to design, visualize, and simulate the products thereby reducing errors, and generating impressive product designs expeditiously.

Inventor is a powerful design accelerator with useful capabilities. All data input methods are user-friendly, and it gives the designer a greater degree of freedom to design and alter the geometry.

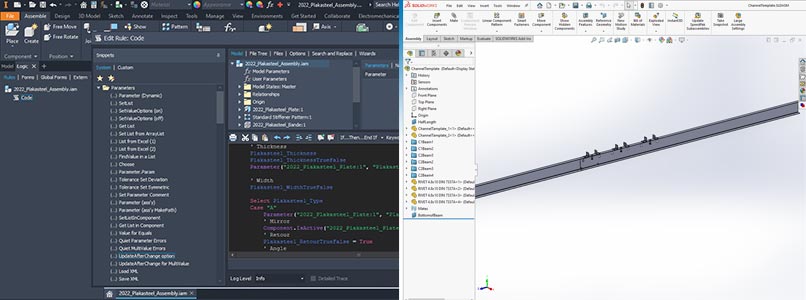

As far as design automation goes, for Autodesk Inventor there is an inbuilt functionality of iLogic. It functions the same as DriveWorks but comes as an inbuilt capability of Inventor.

Design engineers across industries use both these tools to deliver comprehensive 3D CAD models and CAD drafting for mechanical designs. But for modeling tasks like sheet metal, solid modeling, design automation, etc. one can see several differentiating features between these two platforms.

SolidWorks, a Dassault Systèmes product, has carved a niche in engineering designing by establishing itself as a foolproof platform for creating sketch geometries and models. It comes with sheet metal design tools and 3DEXPERIENCE platform for design collaboration. In SolidWorks 2023, users can work with large assemblies (up to millions of parts) with assembly management tools and create precise drawings.

Powerful modeling features of SolidWorks reduce development time, accelerate design development process and improve overall productivity of the design engineers. Many design engineers prefer SolidWorks when it comes to quick turnaround times. Especially in case of sheet metal part designs, SolidWorks offers a dedicated module that facilitates efficient sheet metal design development.

Another great feature for SolidWorks is its ability to automate designs with DriveWorks – an efficient design automation platform. The designer can eliminate redundant modeling and drafting tasks with pre-defined logical scripts and rules. If you purchase a license for SolidWorks, it comes with a free trial version of DriveWorks – DriveWorks Xpress to explore automation capabilities.

Don’t have the time to read the entire article right now?

That’s Ok. Let us send you a copy so you can read it whenever you want to. Tell us where to send it.

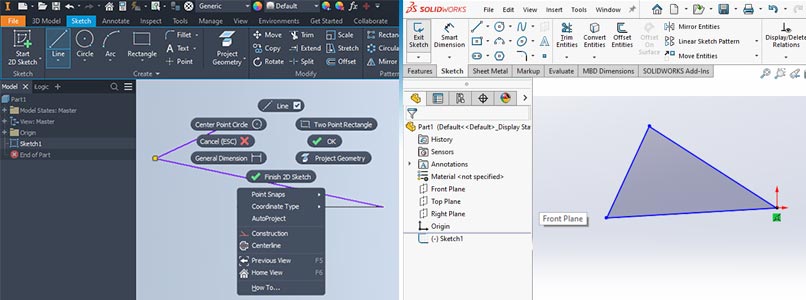

Autodesk Inventor: Inventor has an interactive environment in ribbon that enables using various 2D sketching, 3D modeling and other features. For example, while using a contour in Autodesk Inventor, closing the contour finishes the sketch line. For a dimensioning tool, this 3D CAD platform offers fewer functionalities. The user also needs to use a few more clicks to add aligned dimensions.

Secondly, when it comes to editing, the sketch geometry causes instability at times. Also, the sketch constraints are less user-friendly.

SolidWorks: As compared to Inventor, SolidWorks offers some more user-friendly functionalities. For one, while contouring, the user just needs to press ESC or use double click to finish the line. It also offer advanced functions such as text formatting symbols, comments etc. for ease in dimensioning. As against Inventor, the geometry remains relatively stable.

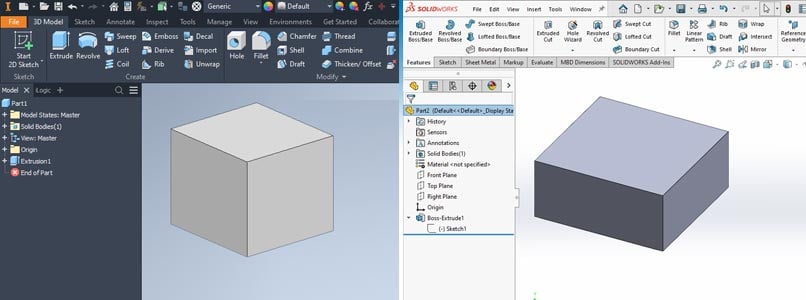

Autodesk Inventor: Inventor 3D CAD modeling is a popular choice and hence a user looks for several features. Features that allow creating complex geometrical shapes faster are popular with design engineers.

Autodesk offers featured like Extrude, Hole Wizard, Sweep etc. which are common for most 3D CAD platforms. One needs to have a defined surface to use features like Extrude and Revolve which cannot be used from offsets. Even the Hole Wizard needs an additional plane to create holes on curved surface.

SolidWorks: On the other hand, SolidWorks appears to be slightly more user-friendly. It has some powerful solid features options that allow users to seamlessly create complex industrial design shapes.

For instance, Extrude and Revolve features in SolidWorks can work with reference as a vertex, surface or an offset from the surface. For Hole Wizard, the user does not need to add an extra plane while creating holes on a curved surface. It also offers the use of profile twist while using Sweep and Bidirectional Sweep commands, unlike Autodesk Inventor where such is possible only in Sweep, and that too in a limited way.

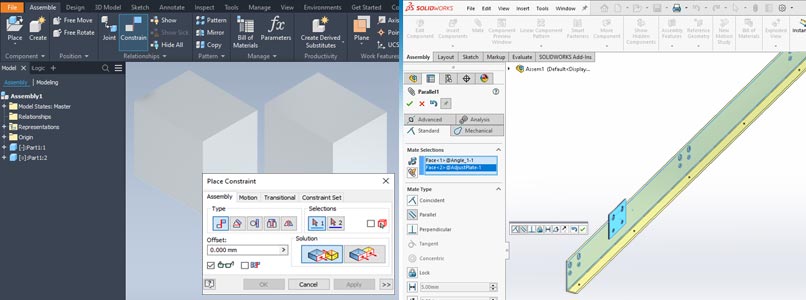

Autodesk Inventor: Inventor software uses joints and parameters to build assemblies. And it has only a few mechanical mates. As the platform uses Ground and Root methods, there are no mates needed and is widely used for furniture 3D modeling. This further eases the conversion in Inventor 3D modeling or of converting Inventor multibody part to assembly.

Now if the designer wants to simulate any parts or effect, the derringer has to define joints using assembly building process. Also, while inspecting assemblies, it offers interference assessment. Dealing with large assemblies is through resolve and express.

SolidWorks: SolidWorks uses only mates while building assemblies and offers an advanced range of mates for features based modeling. So the user has to go through an additional step of creating a 3D sketch plane. The designer can then transfer the features and geometrical parameters from parts to assemblies. In case of assembly inspection, it offers the powers of detecting interference, clearance verification, and hole alignment. Large assemblies are loaded using Large Assembly Modes and Large Design Review.

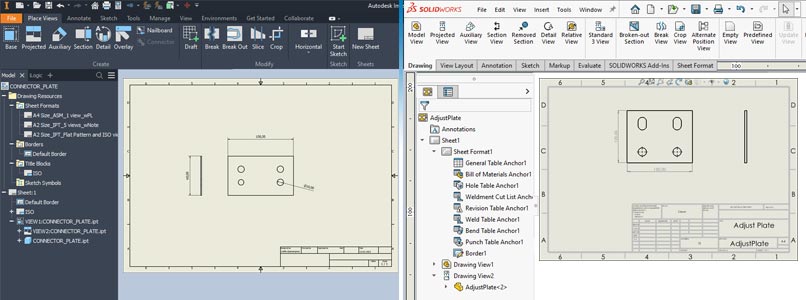

Autodesk Inventor: Autodesk Inventor allows the user to edit and update title blocks, borders and symbols for different sheets. Since Inventor and AutoCAD both are Autodesk products, accessing an AutoCAD file in Inventor is very convenient. This is particularly useful during 2D to 3D CAD conversion or CAD migration from one Autodesk product to another.

For sheet metal corner treatment, Inventor has various options including default features. For example, all corners are rectangular in Inventor sheet metal part.

SolidWorks: SolidWorks has limitations when it comes to editing the title block. The user is allowed to edit it in sheet format option only. During data migration, like converting Inventor to SolidWorks, each file is imported as a STEP or neutral file. Hence there are possibilities of data disruption.

In case of SolidWorks sheet metal parts, the user can define the corner type along with additional sheet metal parameters. One can create different features and generate seamless corner trims.

Autodesk Inventor: Inventor is compatible with a range of CAD applications within the Autodesk ecosystem. This makes design data management easier and hence more designers prefer it. For example, importing and working on files originally created in Revit is seamless in Inventor. It also offers design automation features – iLogic – which is an inbuilt product.

SolidWorks: SolidWorks products cause drawing files to get disrupted when imported from other platforms using neutral file formats. It comes as a standalone license platform to many users. For design automation, it uses a 3rd Party solution called DriveWorksXpress which is free but has limited functionality. For a comprehensive engineering design automation and CAD customization solution, it is required to purchase Solo or Pro version of the DriveWorks.

Autodesk Inventor: Autodesk Inventor, like all other Autodesk products, is available on subscription licensing. The buyer can renew this monthly or yearly depending upon their requirement. It is a relatively cost-effective option if you don’t want to use it for a long time.

SolidWorks: As opposed to this, SolidWorks is the best option for businesses with recurring needs. One can buy a perpetual license. This raises a question. Is the SolidWorks license truly for a lifetime? The answer is obviously no. One has to pay to upgrade it to new major versions of the software. But overall, the total price of SolidWorks license comes below that of Inventor.

While this comparison may not be exhaustive, it is clearly visible that SolidWorks offers more functionalities with each feature to keep the design process glitch-free. That being said, Inventor still has multiple features that come in-built in the standard edition, in comparison to the basic edition of SolidWorks. Additionally, Inventor has a significantly lower initial cost of ownership as compared to SolidWorks.

You may also like

From 2D to 3D: Why Architects are Switching to BIM Modeling