Material callouts in kitchen joinery detail the specifics of which materials are to be used, how thick, type of finish and which edge treatment will be applied to every cabinet part. This detail helps to keep fabrication errors to a minimum & ensures that there are no inconsistencies in the installation process.

Table of Contents

The majority of errors that occur in home kitchen joinery are because of making an incorrect selection of materials. Most often this occurs due to a lack of adequate information provided to fabricators, who then might mistakenly choose to use standard plywood instead of a moisture-resistant product where waterproofing is necessary.

Joinery material callouts helps you eliminate these mistakes and provide the ability to detail board grade, thickness, finish and edge treatment directly into your design. Therefore, you know you are using the appropriate materials for each individual cabinet piece.

This level of detail at the outset provides a great benefit to all parties involved. Fabricators can order the correct materials, installers encounter fewer problems during the fitting process, and the client will receive the kitchen as it was designed.

This also simplifies the process of quality control checks & maintains continuity throughout the project.

Material callouts in detailed joinery drawing for kitchens serve as a critical flag indicating the material, finish and quality required for each individual piece of cabinetry.

While general notes provide an overall guideline for various pieces of cabinetry, material callouts detail the specifics for particular cabinetry pieces.

For example, a general note may indicate the use of water-resistant MDF for all cabinets, whereas a callout for a specific sink base cabinet panel would read, “18mm MR MDF, Grade 2 with 0.8mm ABS edging”. This degree of detail is necessary for good kitchen projects.

Complete kitchen joinery material callouts must address the following essential components:

| Specifications | Details Included |

|---|---|

| Core material | Substrate type (particleboard, MDF, plywood), density grade, precise thickness measurement, board type (standard or moisture resistant) |

| Finish specifications | Finish type (laminate, veneer, lacquer), manufacturer codes for color/pattern, texture (matte, gloss, textured, woodgrain) |

| Edge & support details | Edge banding material, thickness and color code; back panel specifications (finished backs, support panels, dust barriers) |

| Hardware notes | Reinforcement areas for hinges, drawer runners or mounting brackets |

The real benefit of material callouts is that they prevent problems. These specs are your best protection against mistakes, inconsistencies and failures that can harm a kitchen project.

When a drawing spells out what the material is, for example “18mm PB, P2 grade, white melamine both sides, 1mm PVC edging on all exposed edges”, the fabricator knows exactly what to pick.

That means fabricators do not use whatever is available only to find out that it’s the wrong size or finish. For example, if a shelf is supposed to be 18mm but arrives as 16mm, then you have to make a lot of adjustments just to get the shelf pin holes and vertical spacing right.

If there are no detailed callouts for matching finish codes, fabricators will end up with finishes that don’t match and that will show up clearly under the kitchen lighting.

Kitchen environments are a lot tougher on materials than most other rooms in the house. You’ve got wet zones near the sink and dishwasher that need materials that won’t swell in water and dry zones where pantry storage is just fine on standard grade materials.

The key is to have material callouts that clearly differentiate between these zones.

A sink base made from standard particle board instead of moisture resistant MDF will soak up the water from spills and the edges will swell and before long the whole panel will start to fall apart. Panels near the cooktop need to be heat stable.

To get a kitchen cabinetry project looking right, you need to get the right finish. If your kitchen has white shaker style doors and you want it to look uniform, every door, every drawer front and every visible end panel needs to be the same white finish.

When you put those cabinet side by side, any little difference in the finish will come out. Material callouts are key to avoiding all the inconsistencies when you’re referencing codes.

When you put a semi-gloss finish on the top cabinets and a matte finish on the lower ones, even if they have the same color codes, you can tell the difference right away. Same goes for the color codes.

You need to make sure your finishing specs are all lined up. You might choose to have different cabinet finishes inside and out and also on the front and back. But the exteriors must match with proper edge banding.

Get precise kitchen shop drawings with clear material callouts.

Request drawings »Accelerated cabinet shop drawings for kitchen & bath manufacturer

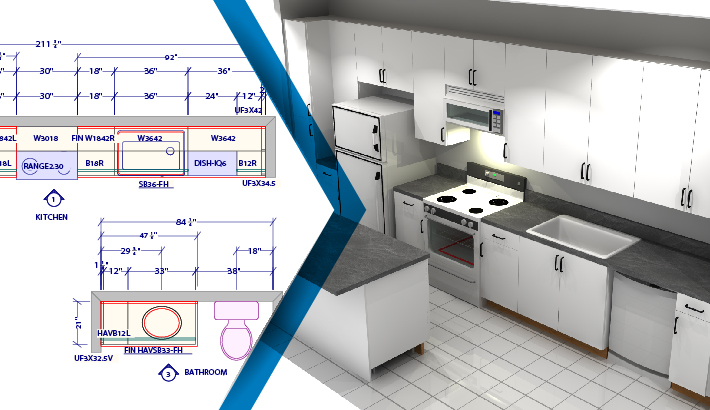

A US manufacturer of frameless kitchen and bathroom cabinets, decorative hardware and countertops were looking at 2D layouts and struggled with what the end product was going to look like or how they were going to manufacture it. They wanted 3D models, detailed shop drawings and accurate material callouts so they could get the job done right and quick.

Hitech CADD Services used 2020 Design to create 3D models from 2D plans and produced accurate shop drawings with all the material callouts on them. In the process they were able to save a lot of time, get the details right and end up with manufacturing ready drawings that were thoroughly quality checked.

The final deliverables led to:

Industry standards and inhouse conventions set the stage for making material callouts that get the message across and keep fabrication workflows running smoothly.

Following the Architectural Woodwork Institute (AWI) standards helps to define material grades, what types of wood can be used for specific jobs and what documentation is required to keep everything running smoothly across different projects.

By having a standard language eliminates all terminology variations that can cause confusion.

When joinery drawings and kitchen cabinet drawings refer to “premium grade” versus “custom grade,” fabricators who are working under AWI standards know exactly what material quality and selection requirements they need to meet.

AWI compliance also requires fabricators to have complete specifications to prevent incomplete callouts that leave critical decisions to fabricator interpretation.

While AWI requirements are a must, successful fabrication shops also develop their own internal standards for consistent formatting and terminology across the board

Keeping everything in line, drawings, legends and schedules requires a bit of coordination to make sure material codes in callouts match the legend entries exactly and that finish schedule references match up with callout identifiers. This makes sure there are no contradictions across the documentation.

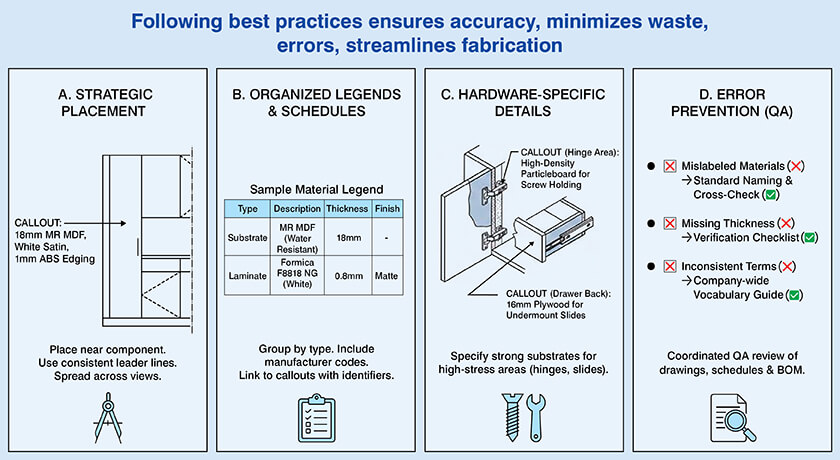

To get callouts right, you need to think about where you are putting them, what they’re saying and how they will flow with the rest of the drawing. That means paying attention to placement strategies, documentation structure, hardware considerations and avoiding making common mistakes.

When you put a callout right next to the component use a leader line to connect the two. So if you’re labelling a cabinet side panel, throw the callout right next to that panel and your fabricators will quickly understand.

In a busy kitchen layout you can quickly end up with too many callouts cluttering up your drawing views. Make sure you are spreading them out over all your views.

If you stick to one style like the same text height, leader line style and arrow config your fabricators can understand and read the whole drawing easier.

Material legends and finish schedules need to be set up in a clear way so you can get the information you need fast. A well-organized legend groups materials by type like substrates, laminates and edge banding. Each entry includes all the details such as thickness options, different grades and exactly what finish is being used.

Using the right manufacturer codes means you avoid any confusion down the line. A finish reference like “Formica F8818 NG” tells you exactly what color and surface texture you’re looking for, so you can’t end up with something that looks similar but isn’t quite right.

When you link a callout to a schedule, make sure to get clear identifiers so you can easily track things down between your drawings and supporting documentation.

When installing hardware, you are dealing with areas that are going to be subject to stress and strain. Hinge mounting areas on doors, for example, get hit with repeated cycles of loading which can cause screws to pull out of low density substrates. Correct material labeling for door components will identify substrates strong enough to take the mounting.

For oversized doors, you will need to call out for some additional support like hardwood blocking or metal plates. Also if you’re installing undermount slides in a drawer cabinet, you need to specify side panel materials that are thick enough not to flex and dense enough to keep the screws in place.

If you’re mounting full extension drawer slides to a back panel, you need something a lot more substantial than a thin dust panel. Your callouts need to spell that out with details on thickness and substrate type.

There are several common mistakes that can undermine the effectiveness of your callouts and lead to problems down the line:

Elevate cabinet fit and finish with clear material annotations.

Contact us »Having accurate and complete material callouts makes a huge difference to a project’s workflow:

Joinery material callout accuracy is the difference between successful completion of a residential kitchen joinery drafting into functional cabinets and failed fabrication. Missing a needed thickness note, a finish code or even a vague description of the substrate can confuse and mislead cabinet makers.

Standardized material labeling is crucial. Fabrication will continue efficiently as long as all of the fabricator’s questions regarding the substrate (what type), the thickness, finish and edge treatment are clearly defined in the callouts.

The quality of your material documentation will directly affect the speed of fabrication and the number of errors encountered during installation. The more detail provided in your material documentation, the less likely the need for onsite modifications.

You may also like

BIM-Based MEP Coordination for Multi-Trade Collaboration