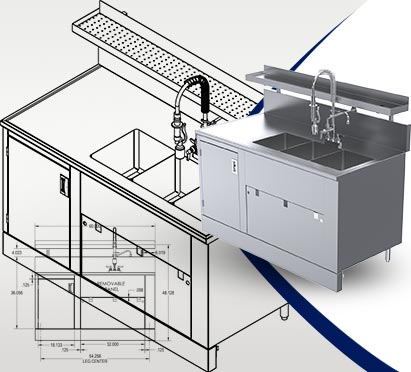

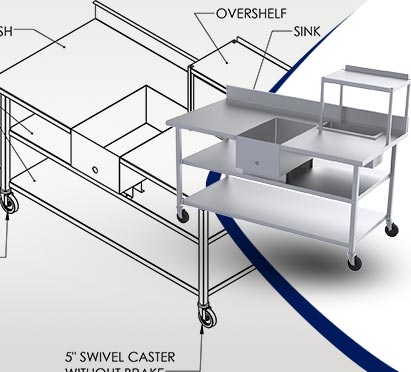

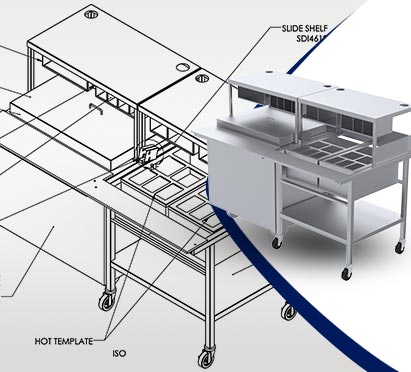

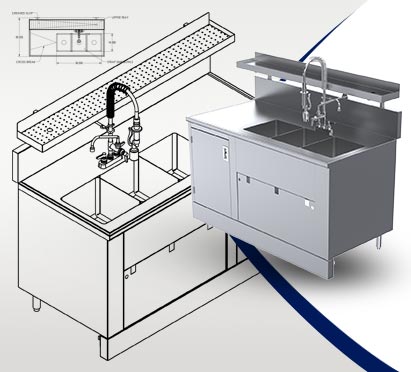

Initially, the team received input architectural drawings to understand the store layout and develop manufacturing drawings accordingly.

MillWork Detailing of Restaurant Kitchen

MillWork Detailing of Restaurant Kitchen

- An initial call was set up with the client’s design engineers to understand details of metal grade and wood type to be used and their manufacturing tooling capabilities

- Team studied the space allocation for placement of various equipment as designed by the store’s architect and compared it with actual dimensions on the construction site

- Based on these details, seeker’s drawings were developed to confirm the spacing set by the client for each section

- Project team manager visited the manufacturing facility of the client to properly develop drawings as per tooling capabilities and avoid iterations

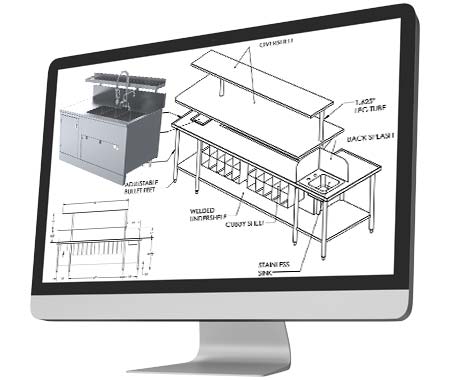

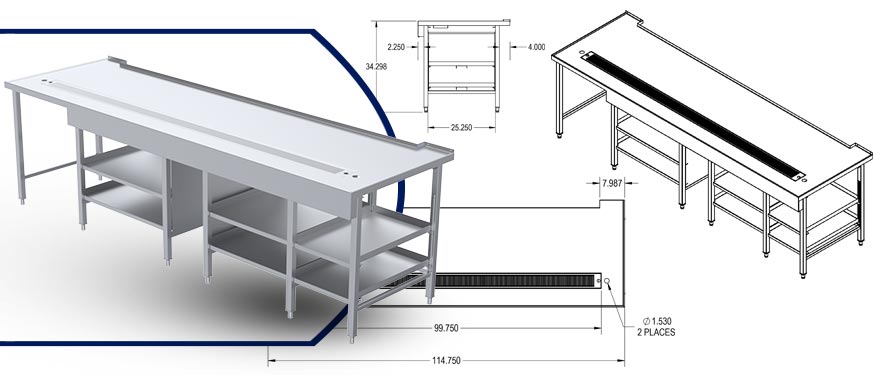

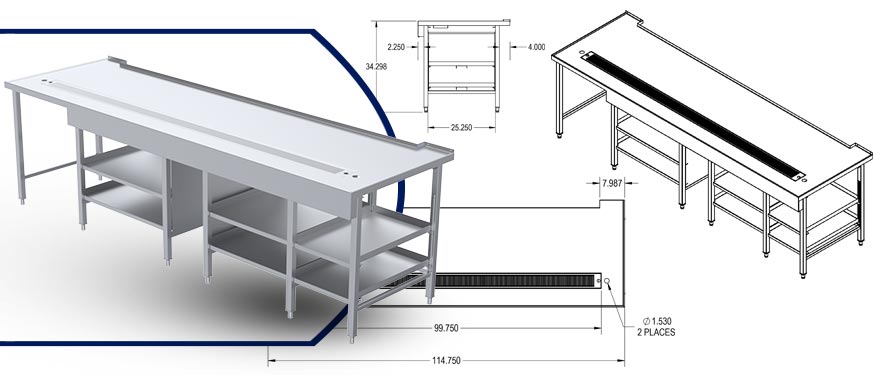

- Once the team had all the details, the team started developing millwork shop drawings for all fit-outs using AutoCAD

- Mostly standard products were used from the in-built CAD library along with filler materials to leave no alcoves

- 3D models were chosen from the library and customized wherever needed

- Final millwork shop drawings were shared with the client after a strict peer QC to ensure meeting quality benchmarks