Millwork detailing enables the creation of both aesthetically pleasing and functional woodwork. Through detailed documentation, the use of digital tools and by adhering to precise tolerances, you are able to ensure that the custom fabricated wood pieces will be manufactured to exact specifications therefore fit properly, be visually appealing and meet the high standards of contemporary architecture.

Table of Contents

The most common problems encountered in designing and building a modern architectural project are the lack of clear definition in the conceptual design, inconsistencies in dimensions or material specifications and the lack of specifics from the architect as to how to manufacture custom fabrication parts. These problems occur primarily due to poor communication between the design team and the shop.

Millwork detailing provides a solution to these problems through a detailed instruction set that translates the architect’s idea into manufacturing information. The instructional set includes detailed drawings, a list of required materials and step by step assembly instructions to ensure accuracy and prevent any potential installation issues.

Therefore, millwork detailing in modern architecture enables the integration of custom wood elements to seamlessly blend with the overall design of the architectural project. This ensures that architectural design meets the contemporary design standards and performs as intended.

Millwork detailing refers to creating a blueprint that details the exact specifications for decorative wood elements, which include custom cabinetry, trim work, paneling and other built-in shelving designs that relate to the overall aesthetic of the architectural style.

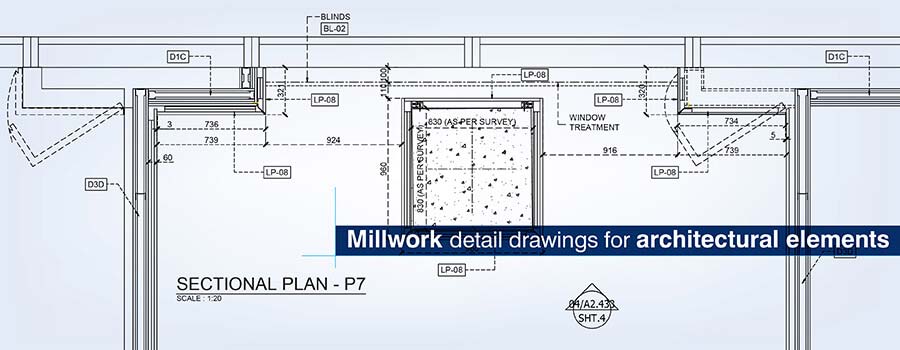

Architectural millwork detailing represents a critical process to connect the architectural drawings and the actual fabrication of the millwork in the workshop. It determines where various materials will interface, where any concealed lighting will be placed behind the woodwork and ultimately defines the final form of the wood components.

Through clear tolerance for each material (usually ±1mm) and determining the direction of the wood grain and the amount of allowance for expansion and contraction, this ensures that the custom woodwork fabricated in the shop fits into place precisely.

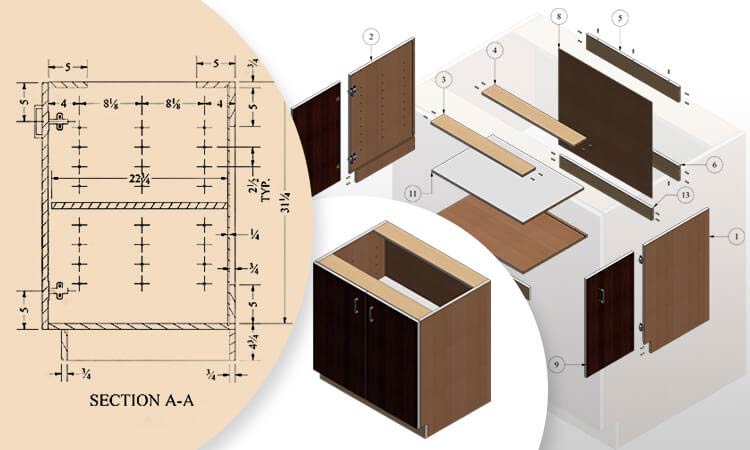

Bring cabinet concepts to life with clear, structured millwork detailing.

Start drafting today»

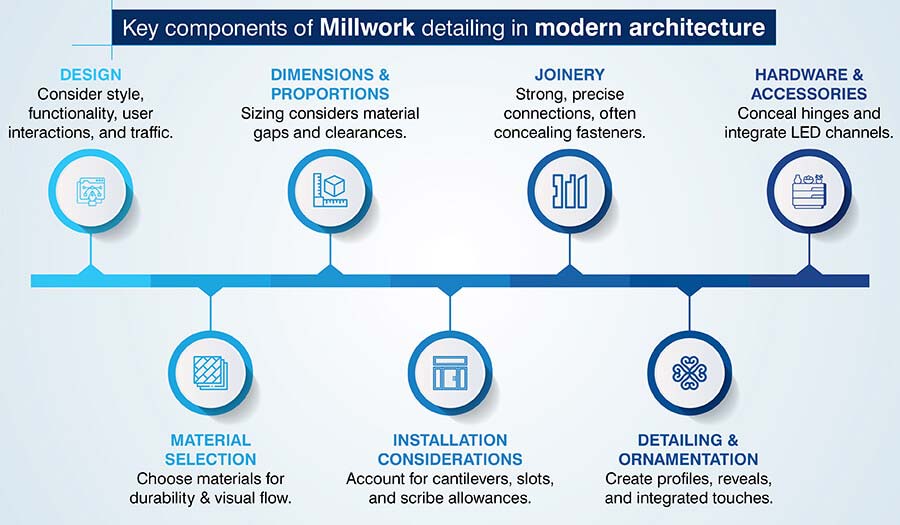

Custom millwork detailing puts together several important elements to create wood elements that fit in with the architectural style and also with the functionality and aesthetic of a modern space.

Following are some of the prime areas of millwork detailing in modern architecture:

Millwork shop drawings take an architect’s vision and turn it into a set of clear instructions that fabricators can use to bring the design to life.

Millwork shop drawings can turn architectural abstract ideas like making something look like it’s floating or seamless into actual engineering decisions such as which type of mounting system to use and how far apart the Z clips should be.

Shop drawings add more detail to the architectural plans what you would normally get from a normal blueprint. They include full-sized drawings of all the critical connections and the dimensioned profiles that show exactly how the shapes and curves fit together.

Cabinetry and trim detailing locks in tight tolerances and tells the fabricators exactly which hardware to use. This all helps to keep the final product as close to the architect’s vision as possible.

The precision and seamless surfaces of modern architecture requires detailers to get creative with designs to make them easier to build:

Getting the reveal and shadow lines right helps give modern installations that perfect, consistent look. Detailers usually standardize on a reveal width of 1/8″ to 1/4″ to make sure everything fits in right.

Cloud based CAD platforms are making real time collaboration easier letting architects, millwork designers and woodworkers work together seamlessly. They get to see the latest designs, make suggestions for changes and follow the evolution of the project as it unfolds.

Parametric modeling lets you make a change to one element and see the ripple effect through the rest of the design. When you tweak a dimension, the whole set of drawings gets updated automatically.

For example, when a designer wants to lift the height of a wall cabinet in a modern kitchen from 36″ to 42″ for a bit more storage, shelf spacing, door sizes, hardware positions and reveal gaps all get adjusted on the fly across all the cabinet units, keeping the modern look intact.

Optimize your production flow with clear millwork detailing in every sheet.

Request a quote»Architectural millwork detailing is essential when it comes to how contemporary spaces actually work, which means it addresses real life requirements without sacrificing the sleek, sophisticated look you want.

When designing dimensioned niches, pull outs and vertical built-ins, you’re essentially finding ways to draw out as much storage as possible in those tight modern spaces. Here’s how some of the creative millwork solutions keep your interior looking sleek while delivering the storage you need:

| Millwork solution | Application | Functional benefit |

|---|---|---|

| Pull out pantries | Kitchen storages | Makes the most of the depth you have, keeps things within easy reach |

| Concealed appliance garages | Countertops | Keeps your countertops looking clean and clutter free |

| Floor to ceiling cabinetry | Vertical walls | Uses up every last bit of space, means more storage |

| Under stair built ins | Transitional spaces | Takes what would be a waste of space and turns it into a useful corner |

When you use proportional detailing, you get a nice flow and hierarchy in interiors, which enhances the story architects are trying to tell with their building. By using millwork, you can create a visual flow by having consistent reveal patterns and repeating vertical elements that tie everything together.

Incorporating multifunctional millwork like a bench that’s built right into a media unit is a great way to keep things functional without having to compromise on your minimalist aesthetic. High-end joinery can really make use of this.

Wood panels get mounted on French cleats or Z clips so they can move with the wood when it expands and contracts. And quirk beads give you a nice 3mm separation when a cabinet meets a plaster wall, which lets the two surfaces move a little without cracking or sticking.

The longevity of millwork depends on factors including the type of wood used, assembly, finish and type of hardware selected.

Detailed wood ornamentation must remain intact and perform its function as expected over an extended period.

The designer selects the type of joinery and protective detail necessary to support the level of use the millwork will experience:

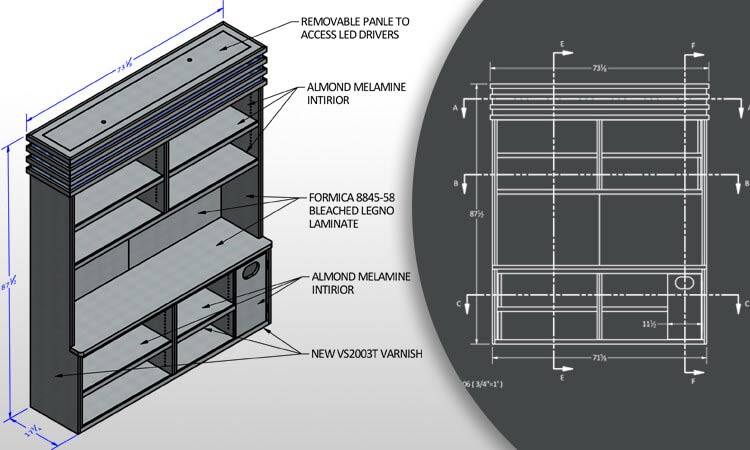

Modern designs conceal elements that require occasional attention. This is achieved through the incorporation of removable panels, typically secured with hidden fasteners, magnetic catches.

Designing handles, shelves & compartments is done by placing them in positions that makes them accessible for every user. This way, handles & shelves can be used by those with limited grip strength, and loop or bar handles work well for this. And tactile edges are added so that visually impaired users can navigate without any trouble.

In modern millwork, we make sure accessibility is added to the joinery so that it looks like it was always meant to be there:

| Accessibility feature | Millwork detail | Drawing specification | Functional benefit |

|---|---|---|---|

| Adjustable height surfaces | Telescoping apron with concealed lift mechanisms | Sectional details showing dual shell construction with reveal dimensions | Accommodates wheelchair and standing users (28″-42″) |

| Motorized pull downs | Heavy duty lifts within false backs | Hardware callouts with lift model numbers and clearance requirements | Brings upper storage to countertop level |

| Angled pipe shrouds | Custom wood panels with push fit fasteners | Exploded views showing 15° angle and fastener locations | Prevents burns, maintains aesthetics |

| Toe kick drawers | Bottom mount heavy duty slides | Plinth elevation with slide capacity ratings and touch latch placement | Converts wasted space into accessible storage |

We also make sure to pay attention to the rules, so that our detailing is in line. This means making sure there is 27 inches of clearance under the counter, that there are zero clearance levels and that all the support elements fit in during the fabrication process rather than having to be tacked on afterwards.

Millwork Detailing Significantly Reduced Turnaround Time for a Joinery Manufacturer

A UK joinery manufacturer was having difficulties with massive workloads, a complete mess of workflows and ordered way of managing custom orders. Turnaround times just kept getting longer, revisions were constant and manufacturing was getting held up. The company needed a better way to turn architectural plans into decent, reliable shop drawings for all their cabinetry and casework.

Hitech CADD Services surveyed the plans, produced the initial drawings for the client for their approval and then created proper 2D AutoCAD shop drawings, Bills of Materials (BoMs), layouts and all the installation instructions. This helped them get manufacturing and fitting on schedule.

The end result was:

Detailed Shop Drawing of Cabinet

Detailed Shop Drawing of Cabinet

Millwork Detailing Drafting

Millwork Detailing Drafting

As contemporary architectural practices continue to evolve, new materials and techniques along with changing priorities, are altering how millwork in modern architecture integrates into the physical environment.

Millwork detailing is the foundation in bringing an architect’s or designer’s vision to life. Here we are concerned with ensuring that custom wood details are functionally correct, technologically correct and aesthetically pleasing as a result of good documentation, proper use of materials and proper workflow processes.

Going forward, the focus will be on doing what is best for the environment, using materials appropriately and integrating new technology while maintaining the visual simplicity.

Architectural millwork detailing will be utilizing digital fabrication technologies to allow for increased customization of details. The changes in these areas will shape how it continues to support innovative & conscience driven architecture.

You may also like

BIM-Based MEP Coordination for Multi-Trade Collaboration