In this comparative analysis, we examine Microvellum and Cabinet Vision, two leading millwork design software options. We evaluate their core functionalities, CNC integration, customization options, pricing structures, and user experiences to guide professionals in selecting the optimal solution for millwork design

Millwork design professionals often struggle to choose between available design software options, unsure of which solution best meets their immediate project needs. Complex modern millwork design works out better with project-aligned tools, regardless of their level of sophistication. However, finding the right balance between functionality and ease of use in software tools against projects remains a frequent matter of debate.

Two leading solutions that address millwork design and drafting workflows commonly come up for discussion. Microvellum leverages AutoCAD integration and handles complex commercial projects. It has deep customization capabilities and comprehensive library management. Cabinet Vision takes an alternative approach with its intuitive interface and specialized cabinet making tools and is particularly suited for residential projects and straight forward CNC integration.

In our Microvellum vs. Cabinet Vision comparison, we have done a detailed millwork design software comparison to help you choose the best CAD software for millwork. By focusing on the core capabilities of these tools, our article helps you decide which of these align best with your project’s scale, technical requirements, and long-term goals.

Table of Contents

Both Microvellum and Cabinet Vision offer a range of capabilities that are crucial for millwork design.

The following are some major useful features that Microvellum provides:

The following are some crucial features of Cabinet Vision:

Both the software is equipped with advanced features in millwork CAD tools. However, they differ considerably in their capabilities.

Microvellum’s integration with AutoCAD provides a familiar drafting environment for architects and designers, allowing seamless shifts between 2D and 3D workflows while maintaining industry-standard file compatibility.

The following are some advanced features and capabilities of Microvellum:

Microvellum’s seamless connection to HOMAG CNC machines has proven instrumental in reducing production errors and improving operational efficiency.

Cabinet Vision offers direct machine code generation and thorough tool path optimization for various manufacturing equipment, which streamlines the shift from design to production.

The software’s parametric design functionality enables automated drafting solutions for woodworking through rule-based modeling, adjusting dimensions and specifications based on predefined parameters.

Cabinet Vision also includes specialized tools for cabinet drafting, such as automated drawer box creation and door and face frame design wizards, simplifying common cabinetmaking tasks. This makes it ideal software for custom furniture design.

For example, a cabinet maker designing a kitchen can use Cabinet Vision’s face frame wizard to quickly generate a face frame with proper stiles, rails, and joinery, adjusting dimensions and styles with ease, saving major design time.

Both Microvellum and Cabinet Vision provide sophisticated CNC integration capabilities, although their approaches to manufacturing workflow automation differ considerably in implementation.

When evaluating millwork design automation tools, manufacturers must consider how each platform handles the change from design to production, particularly regarding machine code generation and post-processor compatibility.

The key differences in CNC integration capabilities for Microvellum and Cabinet Vision are:

Choosing the one with better CNC integration depends on your specific needs. Microvellum’s unified post-processor offers flexibility for shops with diverse machinery, while Cabinet Vision CNC integration may provide more tailored optimization for individual machines. Evaluating your CNC equipment and manufacturing workflow is crucial for determining the best fit.

Streamline your woodworking projects with detailed CAD plans

Contact us Now »As leading CAD software for cabinet makers, both Microvellum and Cabinet Vision enable users to create custom furniture designs through different programming interfaces and methodologies.

Microvellum provides a powerful Python based API that allows for extensive customization and automation. Users can leverage Python scripting to create custom tools, modify existing functionalities and integrate with other software systems. This open architecture provides a high degree of flexibility for tailoring the software to specific needs.

Cabinet Vision offers customization through a proprietary interface that focuses on parameter driven modifications. Users can define parameters and rules to control design elements and automate certain tasks. While this approach may be less flexible than Python scripting, it provides a more structured and user-friendly environment for customization.

Despite their different approaches, both platforms offer a range of customization features, including:

While both Microvellum and Cabinet Vision offer specialized 3D modeling tools for cabinetry, their interfaces cater to different user preferences and experience levels for custom cabinetry design software.

Microvellum’s interface, built upon AutoCAD, presents a familiar environment for users experienced with CAD software. This professional-grade interface offers a comprehensive set of tools and functionalities, but it may present a steeper learning curve for new users.

Cabinet Vision prioritizes user friendliness with a more intuitive and visually driven interface. The software employs design wizards, drag-and-drop functionality and simplified menus to streamline common tasks and reduce the learning curve.

The following table shows a feature comparison between the two tools:

| Feature | Microvellum | Cabinet Vision |

|---|---|---|

| Learning curve | Steeper initial curve | Gradual progression |

| Interface style | AutoCAD-based layout | Proprietary system |

| Customization | Extensive options | Moderate flexibility |

| Navigation | Command-line focused | Icon-driven menus |

| Workspace layout | Multiple viewports | Single window dominant |

Both user friendly millwork design applications accommodate various working styles, with Microvellum emphasizing precision through command based interactions and Cabinet Vision focusing on visual workflow optimization.

When comparing Microvellum pricing and licensing against Cabinet Vision cost structures, you must evaluate both initial investments and long-term value propositions, including maintenance fees, upgrade paths, and technical support packages that impact total ownership costs.

Cabinet Vision typically employs a modular pricing system in which users can purchase individual modules based on their specific needs. This allows for flexibility in tailoring the software configuration to budget and requirements. However, adding multiple modules can increase overall costs.

In contrast, Microvellum offers a more integrated approach with bundled features in comprehensive packages. This can provide a more streamlined experience and potentially lower overall costs compared to purchasing individual modules.

Both platforms often provide flexible payment options, including perpetual licenses with upfront costs and subscription models with recurring payments. Evaluating these options based on your budget and long-term software needs is essential.

Optimizing commercial millwork with Microvellum

A prominent US-based furniture manufacturer required detailed shop drawings for a large commercial project. The client faced significant challenges with resource limitations and needed specialized expertise to handle complex millwork requirements.

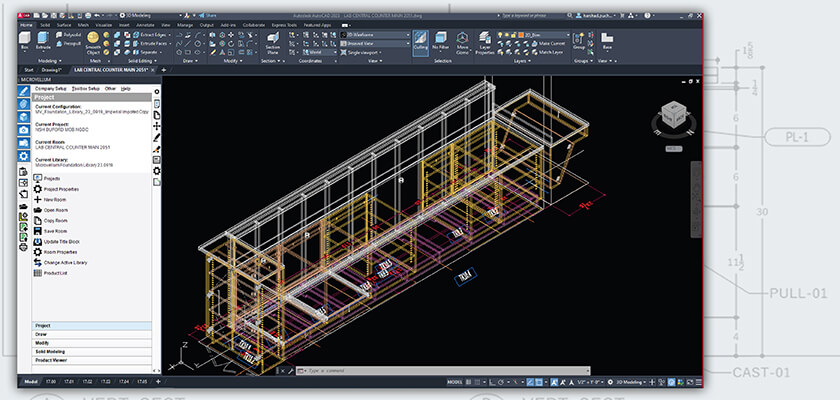

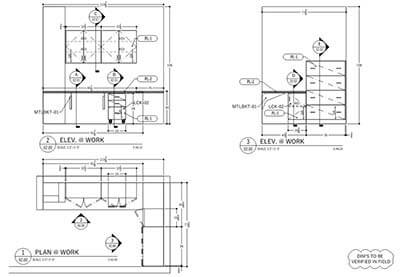

Microvellum CAD Drawing

Microvellum CAD Drawing

Microvellum CAD Modeling

Microvellum CAD Modeling

Hitech CADD Services’ team implemented a structured training approach to overcome these challenges. By leveraging Microvellum’s advanced parametric design capabilities, our specialists created precise shop drawings and comprehensive manufacturing documentation. We leveraged the software’s AutoCAD integration for seamless workflow optimization and accurate CNC-ready outputs.

The final deliverables resulted in:

Streamlining cabinet production with Cabinet Vision

A furniture manufacturer from the US needed specialized millwork shop drawings for commercial cabinet manufacturing project. The client struggled with a lack of trained resources to operate Cabinet Vision for their cabinet manufacturing needs.

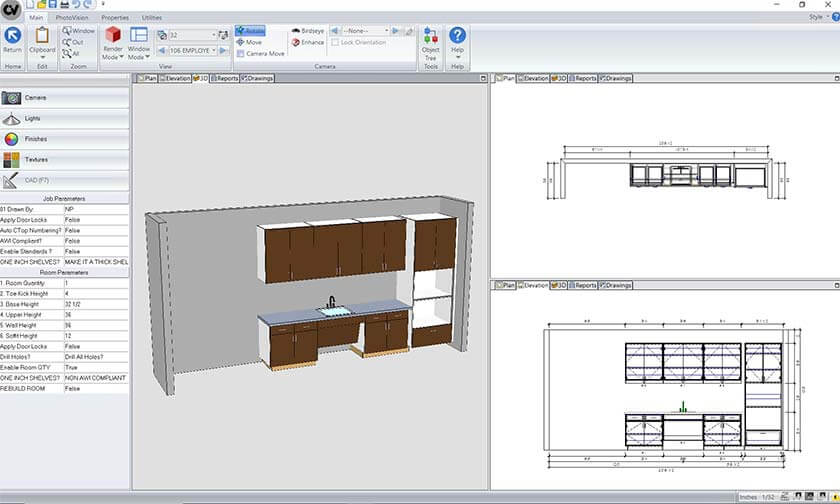

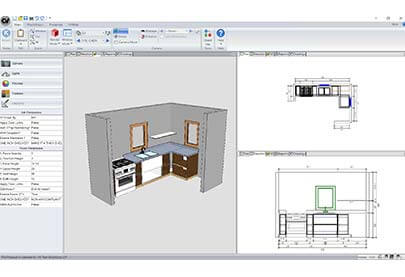

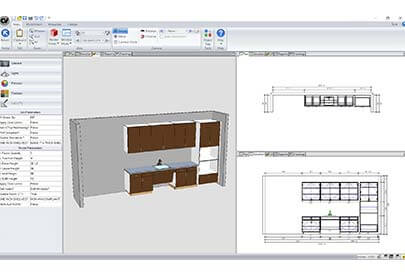

Cabinet Vision Drawings Modeling

Cabinet Vision Drawings Modeling

Cabinet Vision for Drafting Modeling

Cabinet Vision for Drafting Modeling

Hitech CADD Services tackled this challenge by implementing a customized training program focused on Cabinet Vision’s intuitive interface. Our team created detailed shop drawings utilizing Cabinet Vision’s specialized cabinet-making tools and automated features. Using the software’s direct CNC integration features provided comprehensive manufacturing support throughout the production process.

The final deliverables resulted in:

Get precise cabinet shop drawings for seamless manufacturing

Request a quote »Choosing between Microvellum and Cabinet Vision ultimately depends on your specific needs, priorities, and resources. Here’s a breakdown to help you make the best decision:

Recommendations

Both Microvellum and Cabinet Vision typically offer trial periods. You can take advantage of these trials to test the software, explore its features and evaluate its suitability for your specific needs and workflows. Hands-on experience is always crucial in making the right decision.

Both software tools can produce automated shop drawings, but Microvellum features and benefits, with its advanced library-based capabilities and detailed customization options, are often favored.

Yes, both Microvellum and Cabinet Vision integrate with CNC machines, exporting precise data for automated cutting and manufacturing processes.

Microvellum offers extensive customization options with its parametric libraries, while Cabinet Vision excels at simpler parametric designs suitable for smaller-scale or straightforward projects.

Many drafting firms use these tools, as they are industry-standard software for millwork and cabinetry. Microvellum is commonly used for large-scale commercial projects, while Cabinet Vision is more prevalent in smaller residential projects.

To ensure quality, work with experienced firms that specialize in millwork drafting and use advanced software like Microvellum or Cabinet Vision. Request sample projects and check for CNC-ready outputs.

Yes, both tools can manage curved designs, but Microvellum’s advanced 3D design features make it more suitable for intricate shapes and complex custom projects.

Yes, both tools offer plug-ins and add-ons for enhanced functionality. Microvellum has advanced integrations for reporting and workflow management, while Cabinet Vision alternativesinclude add-ons like Cut Rite for optimized nesting.

Yes, both tools support file imports and exports to and from popular CAD software like AutoCAD, SolidWorks, and SketchUp, making them flexible for collaboration.

Microvellum integrates seamlessly with ERP systems, making it ideal for larger scale operations. Cabinet Vision also supports integrations, but its functionality may be limited compared to Microvellum.

Both tools integrate well with CNC machines, but Microvellum is often regarded as superior for large-scale CNC operations due to its advanced G-code generation and machine ready outputs.

Microvellum: Typically, it is more expensive with tiered pricing for libraries, CNC integration, and custom features.

Cabinet Vision: Offers more affordable pricing options, making it ideal for smaller businesses.

Choosing the right software for millwork design is a crucial decision for any business. Microvellum vs Cabinet Vision, which one comes out on top? Both are popular choices, each with its own strengths.

Microvellum excels with its user-friendly interface and powerful automation tools, making it ideal for shops focused on efficiency and high-volume production. It boasts strong integration with CNC machinery and offers excellent customization options for improving efficiency in millwork design processes.

However, Cabinet Vision shines when it comes to complex design capabilities and intricate detailing. Its strength lies in producing highly customized, custom pieces where design flexibility is crucial. Ultimately, the best choice depends on your specific needs and priorities. Consider factors like your typical project complexity, the level of automation you require, and your budget constraints to make an informed decision.

You may also like

BIM-Based MEP Coordination for Multi-Trade Collaboration

How AI and ML are Shaping the Future of Scan to BIM