Manufacturing companies, with help of product design engineers, have embraced mass customized products as an easy way to sail through agile markets. It helps manufacturing units to accommodate a variety of design features by exhausting all the allowable permutations and combinations of design and development ideates. There is a general perception that when consumers are allowed to configure the products according to their requirements, they experience a sense of satisfactory purchase – and manufacturing companies have been leveraging that to a great extent.

For example, every hydraulic cylinder is different from every other hydraulic cylinder, in spite of having the same utility. The geometry, stroke length, piston diameter, volume of the cylinder etc. go on varying from application to application of the cylinder. Even a nail manufacturer is a perfect fit for such an example. Not many of the nails manufactured at a nail manufacturing facility are same in exact geometry or surface finish.

For fabricators and manufacturers, designing custom products isn’t the fundamental concern. Most of the manufacturing firms are equipped with design engineers savvy at using 3D CAD modeling software like SolidWorks or Autodesk Inventor® suite. Lot of manufacturing units outsource product 3d modeling to professional design service providers also. But when the manufacturing lead times are shorter, we think of faster, better and cost-efficient manufacturing methods; and ROIs are counted from the very initial stages.

In such times, practicing mass customization becomes much more dreary process for manufacturers and custom tool setting is really bothersome. Even outsourcing isn’t an option with the kind of time lag between order placement and shipping dates.

Automating repetitive tasks of modeling and drafting is the only alternative left with mass customized product manufacturers.

With mass customization, the production volume is high and so is the product mix. This means, their products are classified as products that have same utility but different form or geometry. Design automation software plugins are the perfect suit for such manufacturers as most of the design and modeling related tasks are automated.

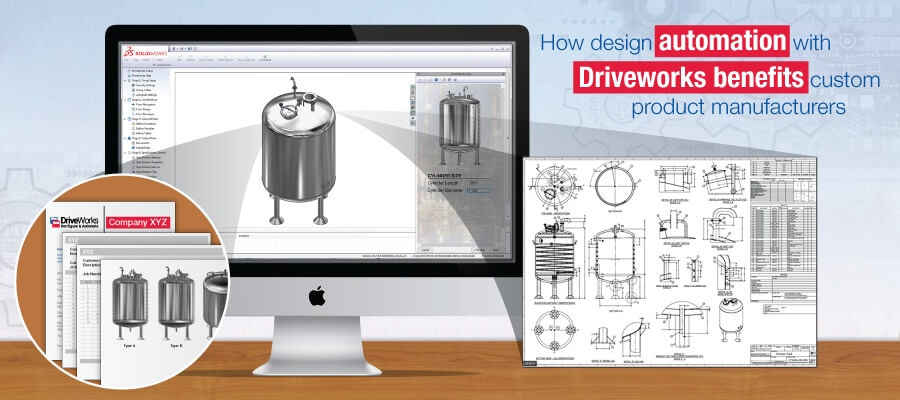

In fact, design automation not only saves time by automating repetitive modeling tasks but also helps manufacturer in setting up the pre-manufacturing requirements through sales configurator. Sales configurator gets manufactures an appropriate set of manufacturing information with fabrication drawings and models. But establishing and developing sales configurator can be a tricky business; to achieve exemplary user experience of buying/placing orders a professional help from design automation service partner can be availed.

Numerous companies working with custom product manufacturing have implemented DriveWorks but the outcome didn’t turn out the way they projected it. Instead of completely automated designing stage, design engineers still work manually on traditional CAD platforms.

An authorized Driveworks expert can successfully automate designs and train your in-house design engineering talent to leverage the maximum of Driveworks with SolidWorks. DriveWorks certified engineers also empower Driveworks implementation of different modules Driveworks Xpress, Driveworks Solo and Driveworks Pro as per the designing, manufacturing and sales capacity as well as the requirement of your firm.

The certified design automation specialist helps in gaining the edge by working alongside your teams and seamlessly implements CPQ tools across your manufacturing capacity. Besides, these specialist engineers have a vast experience of working in different manufacturing sector ranging from machinery to furniture and from industrial equipment to building products.

At Hitech CADD Services, we have dedicated teams of Driveworks authorized specialists having high competence across the Driveworks world. We help you make higher ROIs when counted right from the placement of order to dispatch of the final manufactured product. We can be your next design automation partner to achieve competency for custom product manufacturing, get in touch with us via info@hitechcaddservices.com for next logical step in getting success for custom product manufacturing.

You may also like

Top 5 Architectural BIM Companies to Outsource

Top Sheet Metal Design Outsourcing Companies in 2024

Understanding Digital Twins in AEC: A Comprehensive Overview