Business Needs

Challenges

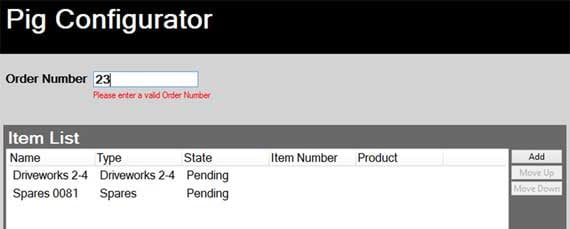

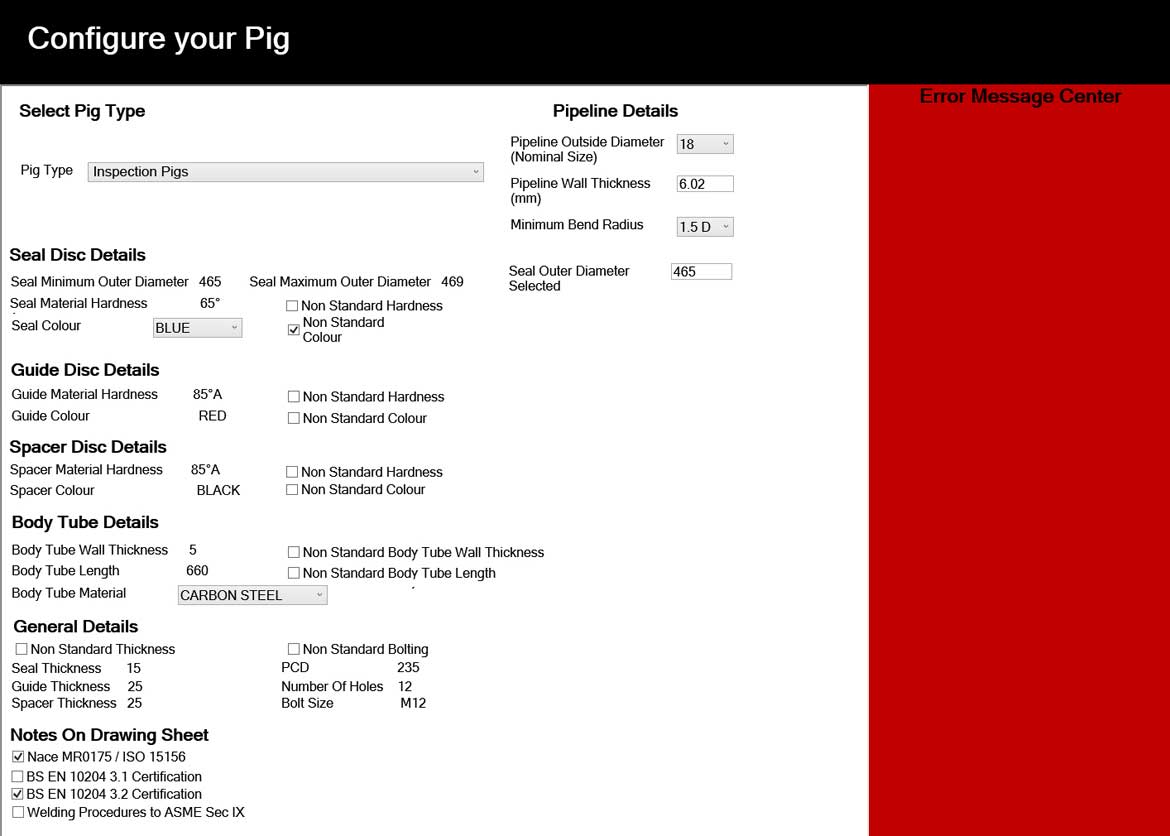

Developed Pig configurator that delivered custom manufacturing drawings and BOMs for shop floor needs.

Client shared the needs for pipe cleaning equipment, types of Pig and brush drives, to be modeled and automate the designs to save time and costs. Based on it, the project team at Hitech, developed SolidWorks base frame models of parts and automate those using DriveWorks. Final CAD configurator was developed which delivered custom manufacturing drawings and BOMs for shop floor needs.

By implementing design automation for the whole process, we empowered the manufacturer to eliminate the repetitive tasks and errors in design process. The client was also benefited by subtraction of manual calculation and could offer a range of design options at a fast pace.