Business Needs

Challenges

Developed process tank configurator that helped manufacturer to enabled same day manufacturing and improved sales revenue.

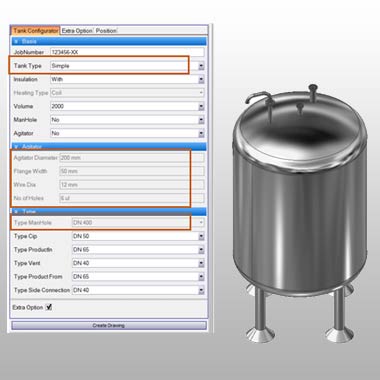

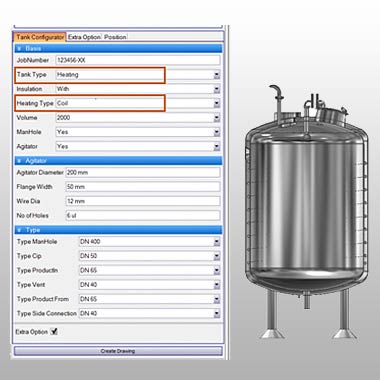

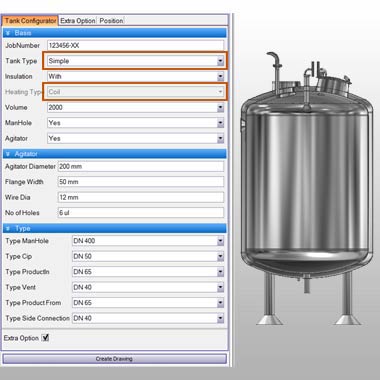

The industrial equipment manufacturer needed to implement Build-To-Order (BTO) manufacturing practices for which client partnered with our design automation specialists to develop CAD configurator custom tanks. Our industrial design engineers leveraged Inventor and iLogic to automate the designing and 3D modeling part.

With the process tank configurator the manufacturer could produce custom tanks and practice ETO and bespoke manufacturing with quality without much lead time. Same day manufacturing was enabled at the manufacturers end and could see clear improved sales revenue.